- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2021-09-15 Origin: Site

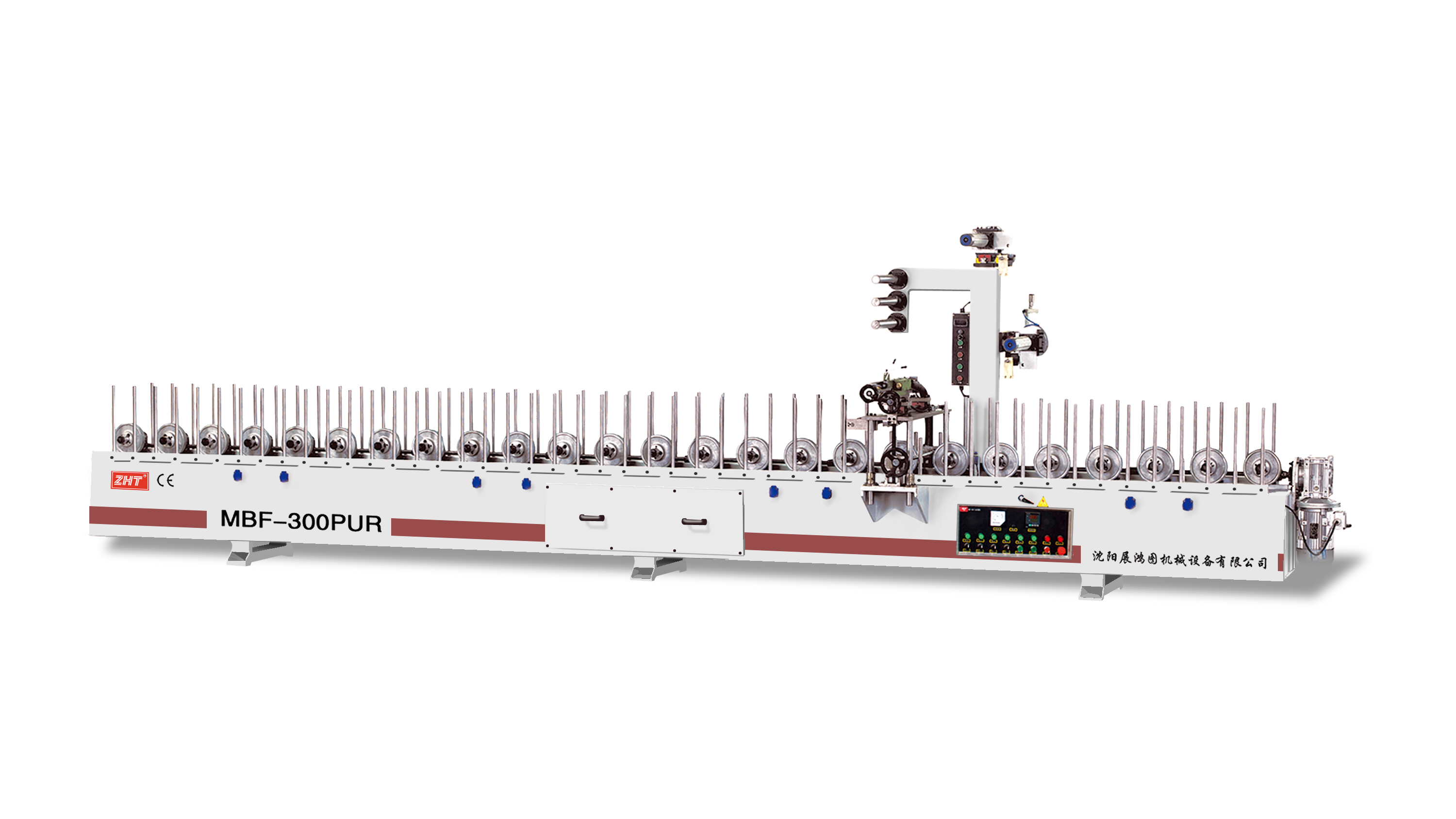

The universal coating machine is suitable for the production of PVC, decorative paint paper, and solid wood veneer on the surface of various lines such as wood, aluminum-plastic profiles, and foam materials. Instead of the traditional paint process, it is used for the production of surface coverings such as door liners, skirting lines, gussets, curtain rods, window sills, aluminum alloy doors and windows, and photo frames.

Working principle of line wrapping machine

Adopt various molding press wheels to simulate the manual veneer action, and attach the surface decoration material to the surface of the substrate. Generally, the center line or point or highest point of the profile is selected as the starting point. The second fixed position forms the envelope of the profile profile. When the profile moves in the conveying direction, the glued decorative material is rolled point by point through the pressing roller and the forming wheel to realize the combined work of the two.

Installation and Precautions:

1. Determine 2-3 operators of the machine. The equipment should be installed in a workshop with a clean environment and a flat floor. After the equipment is in place, remove the accessories from the machine, check and verify according to the packing list.

2. Adjust the anchor bolts to make them evenly stressed, so that the machine body reaches a level state.

3. Check whether the equipment is damaged by bumps during transportation.

4. Power supply: This machine adopts 380V three-phase four-wire power supply. The power cord should be larger than 2.5mm², and the right one of the power inlet cord is the neutral wire. The machine installs the grounding wire in accordance with the grounding standard. Turn on the power to check whether the motor, heater, lighting, etc. are normal.

Debugging:

1. Profile positioning: take a manufactured profile, requirements: it cannot be bent or twisted, put it on the bed conveyor wheel, adjust the distance between the two rows of conveyor wheels according to the profile width, shape and covering requirements ; Adjust the width and height of the leaning ruler and the platform to make it suitable for the coating requirements of the profile; install the guide wheels on both sides to make the profile and the conveying wheel parallel to the direction of movement.

2. Installation and adjustment of the pressure roller: Install and adjust the small pressure roller according to the profile surface profile. Generally, select the center line or section of the profile, the point or the highest point of the main curve of the profile, and transition and roll along the profile line point by point. The profile and the diaphragm are compounded together. To install the small pressing wheel, the line must be balanced, and the left and right sides should be carried out at the same time. There is a pressure roller on the top, and a supporting roller must be installed at the bottom to balance the line up, down, left, and right. Otherwise, there will be unrealistic phenomena at the line joints. The large plane can be rolled gradually from the center to the two sides with a small pressing wheel. At a 90° corner, the small pressing wheel needs to be used for three gradual turning angles. For lines with complex shapes, the small pressing wheels need to be arranged naturally and cannot be forced to form. Especially the pasting of decorative paper should be more natural and smooth.

3. The use of glue box or roller coating system

⑴. Operation method of cold glue box:

① Unloading method of the glue box: Lift the glue box steadily, and the glue box will naturally leave the platform.

②Adjustment of glue layer thickness: Turn the lifting bolts on both sides of the glue box to adjust the glue layer thickness.

⑵, the use of roller coating device:

The thickness of the glue layer can be adjusted by turning the glue squeegee on the glue box. Turn the adjustment handle clockwise to thicken the glue layer; turn counterclockwise to make the glue layer thinner. Until the glue is evenly applied.

4. Diaphragm installation and glue adjustment

Install the cut film on the film hanging shaft, adjust the position, lift the glue box, the film passes through the upper film guide roller, pass through the gap at the bottom of the glue box, add glue to the glue box, pull off the inclined iron, The distance is slightly narrower than the width of the diaphragm. Adjust the screws on both sides of the front end of the glue box to control the thickness of the glue. The thickness of the glue depends on the type of glue, generally 50-100 grams of glue is used per square meter.