- All

- Product Name

- Product Keyword

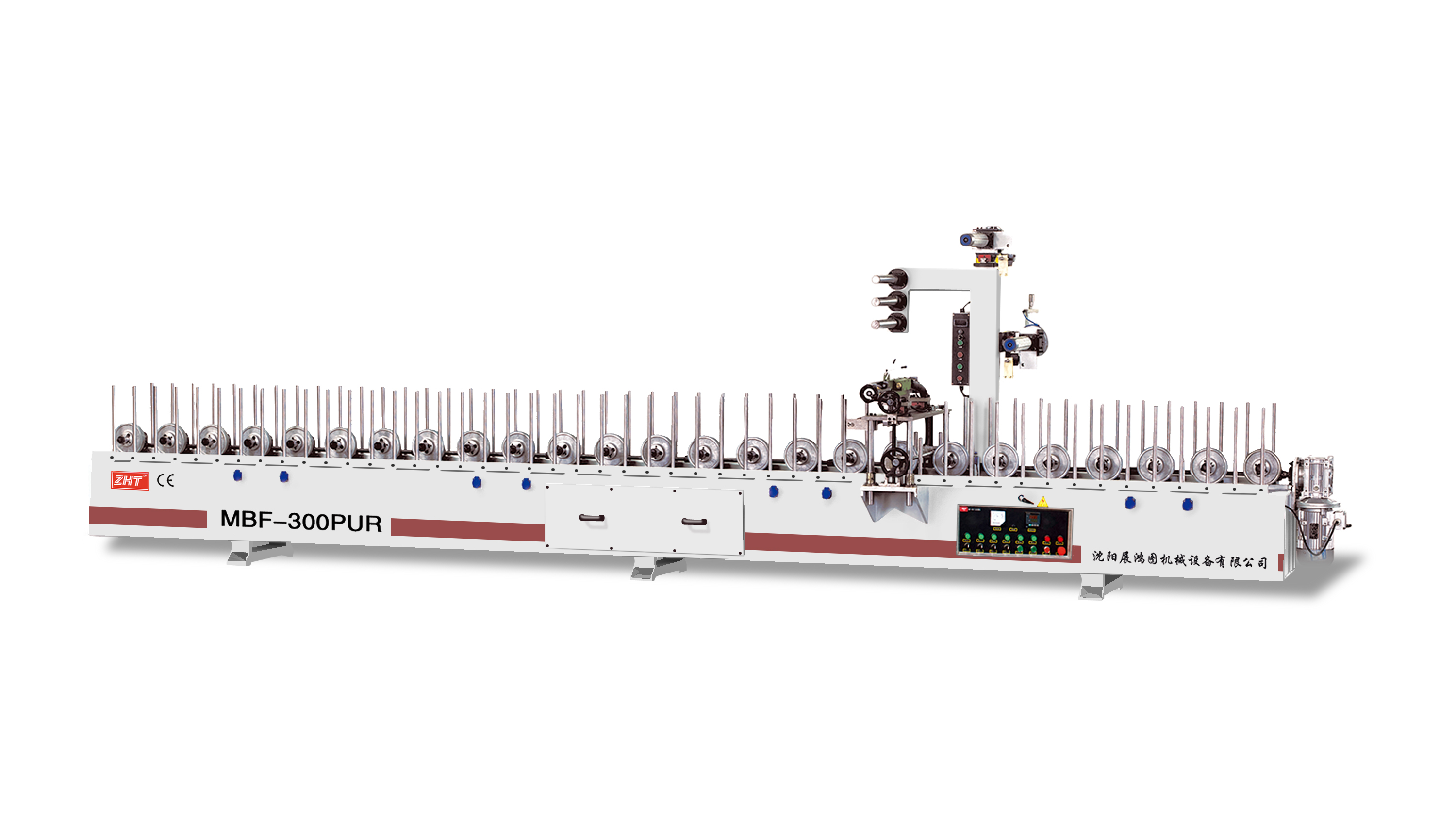

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2021-09-29 Origin: Site

The working principle of the covering machine generally selects the center line or the highest point or the lowest point of the profile as the starting point.

When the profile moves in the conveying direction, the glued decorative material is rolled point by point through the pressure roller and the forming wheel to realize the combined work of the two.

Ranges available

The universal coating machine is suitable for the production of PVC, decorative paint paper, and solid wood veneer on the surface of various lines such as wood, aluminum-plastic profiles, and foam materials. Instead of the traditional paint process, it is used for the production of surface coverings such as door liners, skirting lines, gussets, curtain rods, window sills, aluminum alloy doors and windows, and photo frames.

Working principle

Using various molding press wheels to simulate the manual veneer action, attach the surface decoration material to the surface of the substrate. Generally, the center line or the highest point or the lowest point of the profile is selected as the starting point. The positions are fixed sequentially to form the envelope of the profile contour.

Raw materials

1. Substrate: wood molding, medium density board, wood plastic, plastic steel, PVC, aluminum profile and other lines. Base material requirements: it is a regular line profile, which can have grooves and curved surfaces, but each point must be a straight line in the longitudinal direction, with a certain pressure resistance, and the length is generally more than 40 cm to infinite.

2. Veneer materials: PVC decorative film, decorative paper, solid wood leather, Boeing board, composite aluminum film, etc. The width is determined according to the needs of the substrate and the selected model, generally less than 50 cm.

For example, the widest laminating width of the 300-type universal laminating machine is 30 cm. Generally used in rolls. There are also extra-wide profiles of about 100 cm on the market. The solid wood leather can be rolled or single. The solid wood leather is generally with a non-woven fabric on the bottom surface. The surface material without non-woven fabric must not penetrate through the glue, and it is easy to break when cornering.