- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

electrostatic coating equipment

ZHT

MDF electrostatic coating equipment

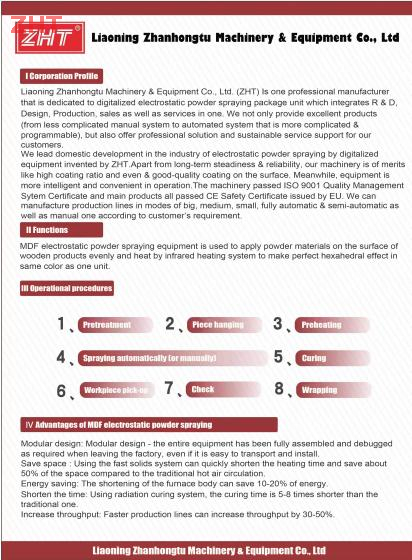

Company Profile :Liaoning Zhanhongtu Equipment Co., Ltd. is a professional equipment manufacturer dedicated to the production of special-shaped veneers. The factory covers an area of 30,000 square meters with over 100 employees. The company aims to be the pioneer enterprise in special-shaped veneer equipment, adhering to customer-centricity and continuous innovation based on market demand, earning respect and trust in the industry.

Company Profile :Liaoning Zhanhongtu Equipment Co., Ltd. is a professional equipment manufacturer dedicated to the production of special-shaped veneers. The factory covers an area of 30,000 square meters with over 100 employees. The company aims to be the pioneer enterprise in special-shaped veneer equipment, adhering to customer-centricity and continuous innovation based on market demand, earning respect and trust in the industry.

Products Liaoning Zhanhong Machinery Equipment Co., Ltd. specializes in special-shaped veneer equipment. Main products include vacuum laminating machine, MDF electrostatic powder spraying series, wooden door laminating equipment, paint-free door equipment, and coating machine. The company has developed more than 30 varieties, widely used in various industries, such as molded cabinets, solid wood veneer cabinets, solid wood composite doors, paint-free doors, wooden doors, panel furniture, and audio. It has achieved international advanced levels, especially in the high-gloss PVC series.

Enterprise Strength Liaoning Zhanhong Machinery Equipment Co., Ltd. holds national invention and utility model patents. Their self-developed automatic pad positive and negative pressure laminating machine equipment has reached international leading technical levels. Products have passed EU CE safety certification. The company has developed and produced various models, including positive and negative pressure laminating machines, automatic high-gloss laminating machines, and more.

MDF Electrostatic Coating Equipment Introduction and Advantages MDF electrostatic coating equipment uniformly coats powder material on wood product surfaces through electrostatic spraying. It achieves a perfect, uniform color effect on all six sides through an infrared heating system.

Process Principle - MDF Electrostatic Coating Equipment MDF powder spraying technology is a surface treatment for medium fiberboard. Powder coating is evenly adsorbed on the MDF board through static electricity, serving as an alternative to painting. The process involves heating the MDF to make it a conductor and using static electricity to adsorb powder on the surface.

Process Principle - MDF Electrostatic Coating Equipment The process includes powder recycling and reuse, short spraying time, low labor cost, and high powder recycling rates. Electrostatic spraying involves releasing high-voltage static electricity, forming an electric field between the spray gun and the workpiece.

Advantages of MDF Electrostatic Powder Coating

1. Modular design for easy transportation and installation.

2. Space-saving with a fast solid system, saving about 50% compared to traditional methods.

3. Energy-saving with total power at 240kw/H.

4. Shortened time with a radiation curing system, 5-8 times faster than traditional methods.

Staff configuration: 3 people for manual work.

Increased throughput: Faster line speeds can increase throughput by 30-50%.

Site requirements: length 60 meters * 15 meters * 5.5 meters

Parameter

Power: 3-phase 4-wire system, 380V, 50HZ

Total power: 240KW

Installation size: length ≥ 38m, width ≥ 8m, height ≥ 5.5m

Total weight: about 12T (Configuration and length differences)

Fan parameters: 1.1KW, 380V

Heating tube parameters: Medium wave infrared heating

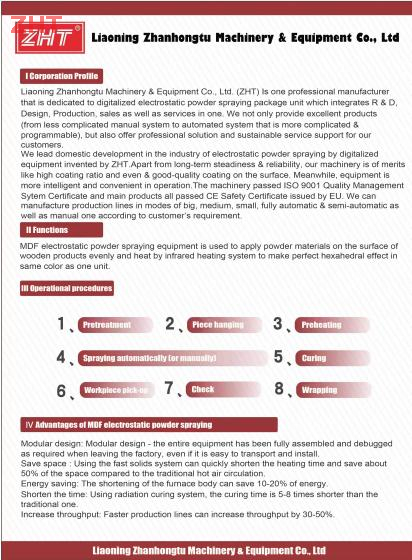

Company Profile :Liaoning Zhanhongtu Equipment Co., Ltd. is a professional equipment manufacturer dedicated to the production of special-shaped veneers. The factory covers an area of 30,000 square meters with over 100 employees. The company aims to be the pioneer enterprise in special-shaped veneer equipment, adhering to customer-centricity and continuous innovation based on market demand, earning respect and trust in the industry.

Company Profile :Liaoning Zhanhongtu Equipment Co., Ltd. is a professional equipment manufacturer dedicated to the production of special-shaped veneers. The factory covers an area of 30,000 square meters with over 100 employees. The company aims to be the pioneer enterprise in special-shaped veneer equipment, adhering to customer-centricity and continuous innovation based on market demand, earning respect and trust in the industry.

Products Liaoning Zhanhong Machinery Equipment Co., Ltd. specializes in special-shaped veneer equipment. Main products include vacuum laminating machine, MDF electrostatic powder spraying series, wooden door laminating equipment, paint-free door equipment, and coating machine. The company has developed more than 30 varieties, widely used in various industries, such as molded cabinets, solid wood veneer cabinets, solid wood composite doors, paint-free doors, wooden doors, panel furniture, and audio. It has achieved international advanced levels, especially in the high-gloss PVC series.

Enterprise Strength Liaoning Zhanhong Machinery Equipment Co., Ltd. holds national invention and utility model patents. Their self-developed automatic pad positive and negative pressure laminating machine equipment has reached international leading technical levels. Products have passed EU CE safety certification. The company has developed and produced various models, including positive and negative pressure laminating machines, automatic high-gloss laminating machines, and more.

MDF Electrostatic Coating Equipment Introduction and Advantages MDF electrostatic coating equipment uniformly coats powder material on wood product surfaces through electrostatic spraying. It achieves a perfect, uniform color effect on all six sides through an infrared heating system.

Process Principle - MDF Electrostatic Coating Equipment MDF powder spraying technology is a surface treatment for medium fiberboard. Powder coating is evenly adsorbed on the MDF board through static electricity, serving as an alternative to painting. The process involves heating the MDF to make it a conductor and using static electricity to adsorb powder on the surface.

Process Principle - MDF Electrostatic Coating Equipment The process includes powder recycling and reuse, short spraying time, low labor cost, and high powder recycling rates. Electrostatic spraying involves releasing high-voltage static electricity, forming an electric field between the spray gun and the workpiece.

Advantages of MDF Electrostatic Powder Coating

1. Modular design for easy transportation and installation.

2. Space-saving with a fast solid system, saving about 50% compared to traditional methods.

3. Energy-saving with total power at 240kw/H.

4. Shortened time with a radiation curing system, 5-8 times faster than traditional methods.

Staff configuration: 3 people for manual work.

Increased throughput: Faster line speeds can increase throughput by 30-50%.

Site requirements: length 60 meters * 15 meters * 5.5 meters

Parameter

Power: 3-phase 4-wire system, 380V, 50HZ

Total power: 240KW

Installation size: length ≥ 38m, width ≥ 8m, height ≥ 5.5m

Total weight: about 12T (Configuration and length differences)

Fan parameters: 1.1KW, 380V

Heating tube parameters: Medium wave infrared heating