- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

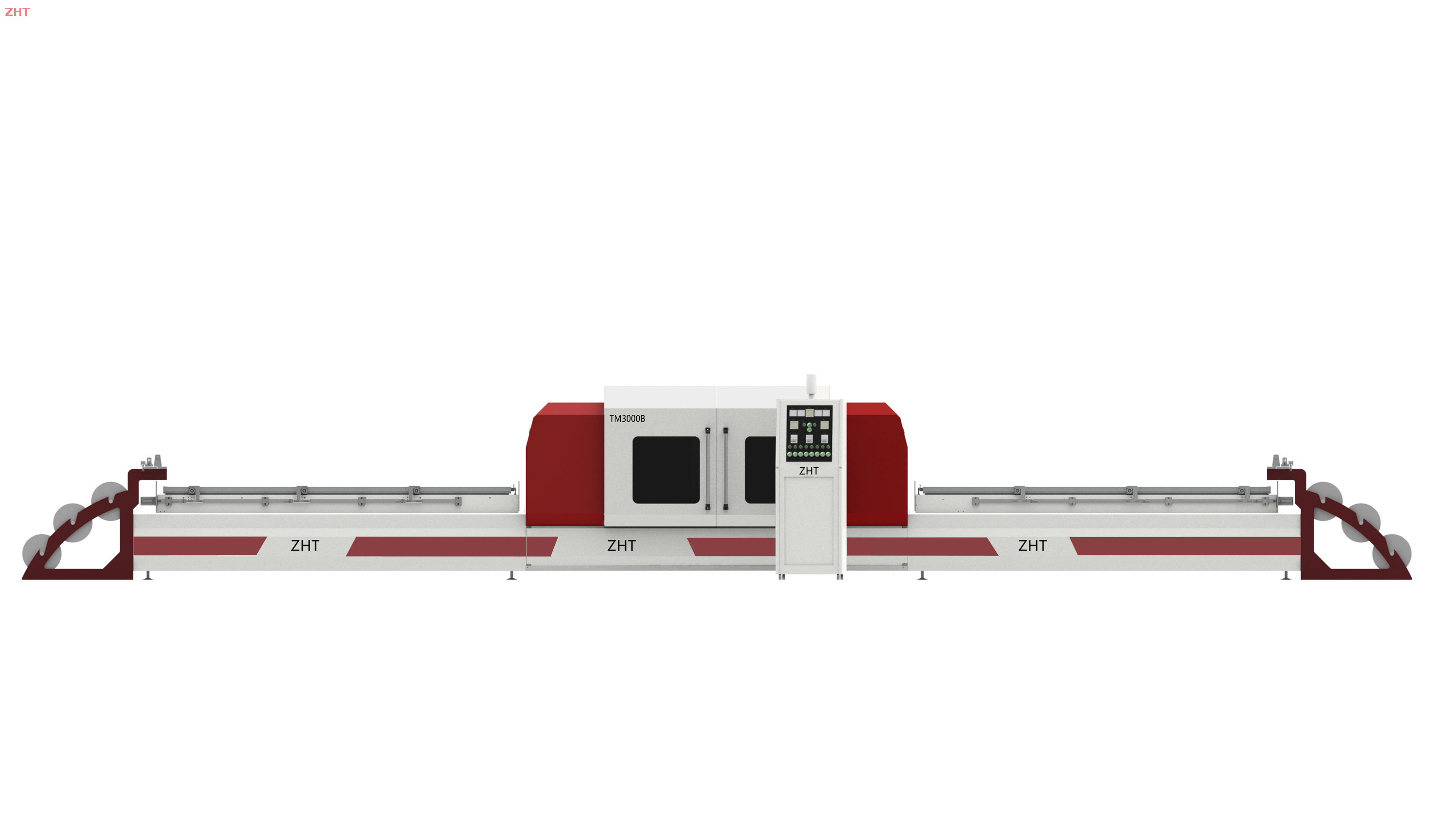

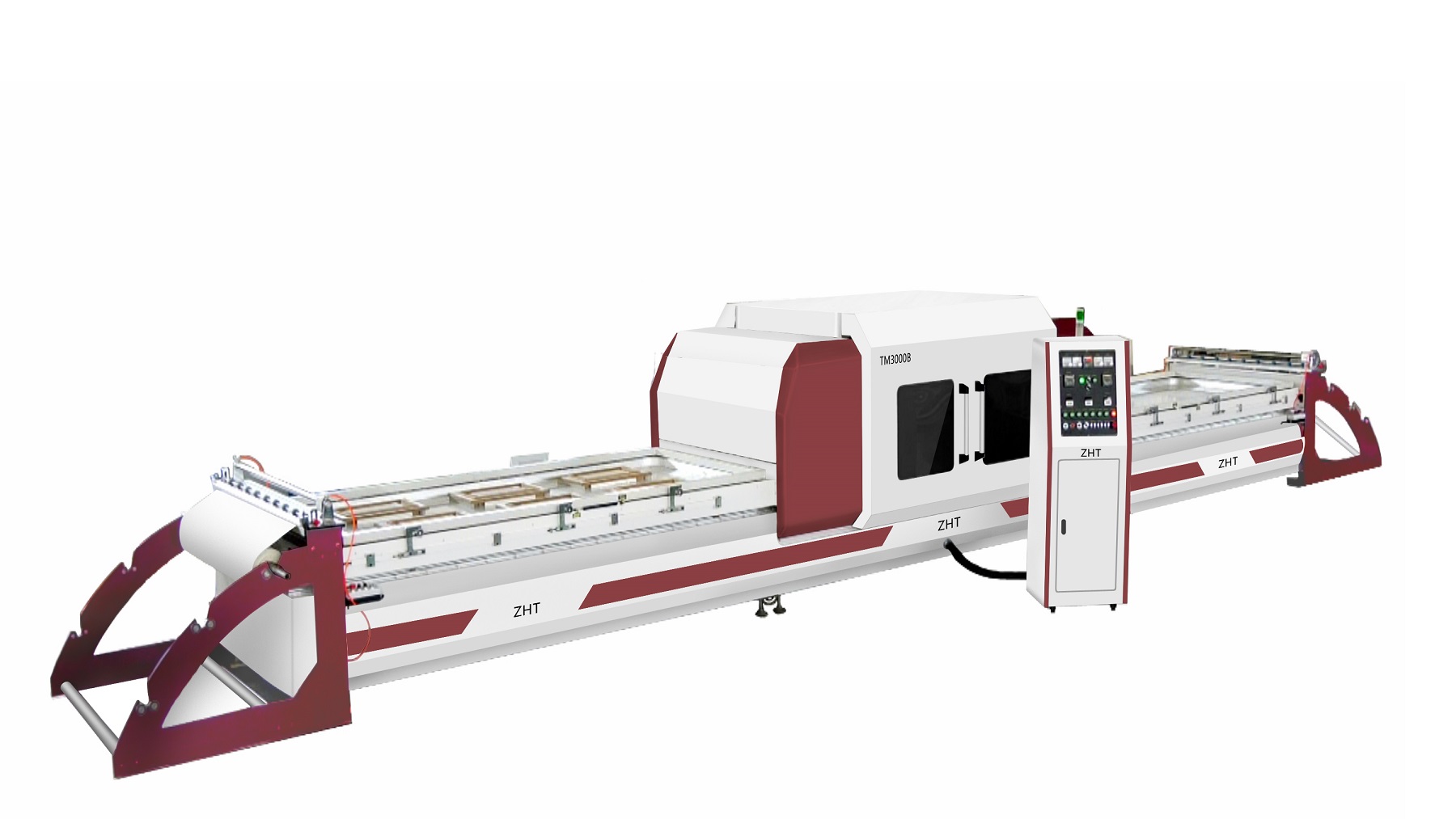

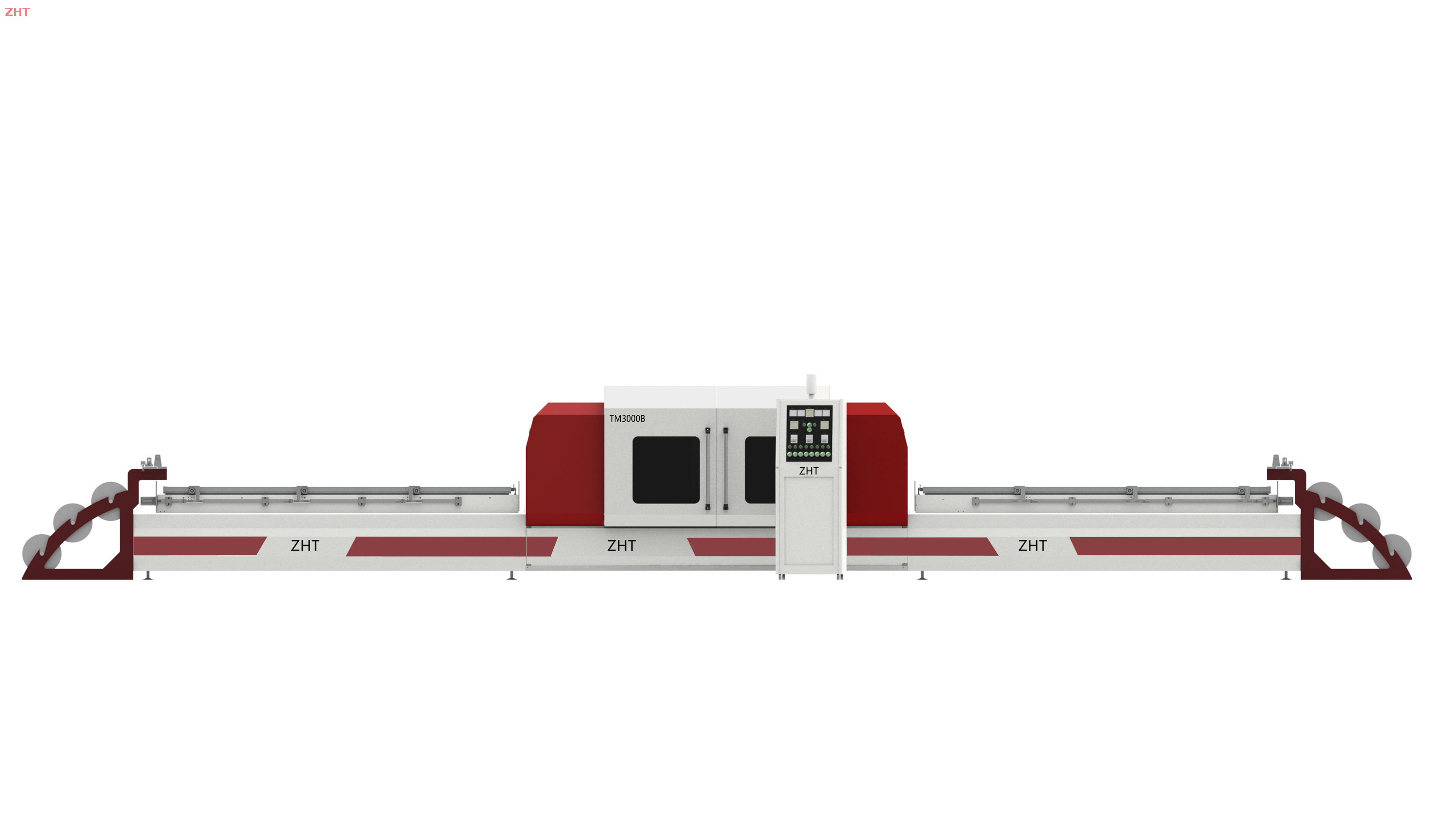

TM3000B

ZHT

Hot Vacuum Press

Function

1. It fully demonstrates that the equipment can be used rationally and pleasantly.fully take equipment structural, materials and other conditions into consideration, so the operator's working gesture is more in line with the the principle of ergonomics, to provide workers with a comfortable and safe working environment,to reach an optimize efficiency.

2. This machine is equipped with automatic locking device, Press film covering device, automatic table running device and so on. The process is smooth and tightly one-stop production.

3. The machine is highly automation and is easy to operate. The warehouse is automatically operated and transmitted. The processing time, temperature and vacuum degree of the work piece are automatically controlled by digital display, so that the function of high-gloss PVC is achieved. The heating system is heated by aluminum plate, so it can maintain a uniform strength heat, thereby improved the percentage of qualified products.

4. This high-performance membrane press machine developed by our technicians from studying the characteristics of PVC film. It solves the problem that ordinary positive and negative press machine can not properly dealing high-glossy work piece.

5. This machine adopts unique heating process, large processing work-surface , which can both greatly improves production efficiency and saves cost;

6. The transmission system leases chain drive, adopts two-stage deceleration to prevent misalignment, avoid product wasting; computer system adopts imported electrical appliances with stable work performance , equipped with manual operation procedures with high degree of automation. This machine equipped with the largest worktable area in Asia.

Technical parameter

Outline dimension | 12500mm x2100mm x1700mm |

Bed dimension | 3000mm x1300mm |

Maximum machining height | 60mm |

Total power | 45KW |

Total weight | 4T |

vacuum degree | ≤-0.095Mpa |

Electrical component list

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1 | 1 | Chint | ||||

3 | ammeter | 85L1 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

How it works

v Preheating equipment

v Put product on the workbench

v Pull the PVC membrane and cover cabinet door

v Cutting pvc film

v Enter the machine

v Vacuum plus negative pressure

v Release of negative pressure

v Workbench out

v Trimming

v Work end

This process is done automatically by one click

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance

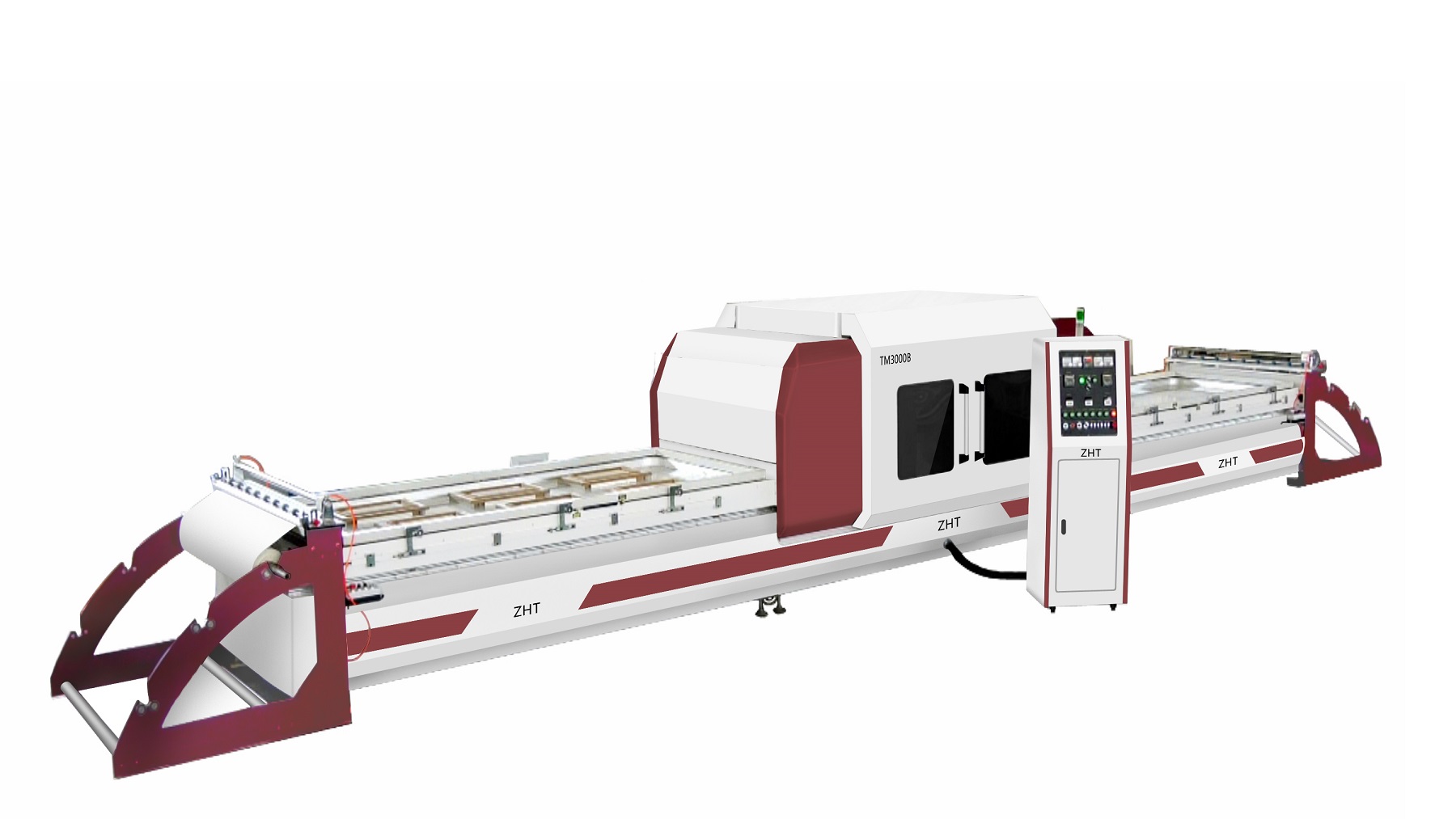

Hot Vacuum Press

Function

1. It fully demonstrates that the equipment can be used rationally and pleasantly.fully take equipment structural, materials and other conditions into consideration, so the operator's working gesture is more in line with the the principle of ergonomics, to provide workers with a comfortable and safe working environment,to reach an optimize efficiency.

2. This machine is equipped with automatic locking device, Press film covering device, automatic table running device and so on. The process is smooth and tightly one-stop production.

3. The machine is highly automation and is easy to operate. The warehouse is automatically operated and transmitted. The processing time, temperature and vacuum degree of the work piece are automatically controlled by digital display, so that the function of high-gloss PVC is achieved. The heating system is heated by aluminum plate, so it can maintain a uniform strength heat, thereby improved the percentage of qualified products.

4. This high-performance membrane press machine developed by our technicians from studying the characteristics of PVC film. It solves the problem that ordinary positive and negative press machine can not properly dealing high-glossy work piece.

5. This machine adopts unique heating process, large processing work-surface , which can both greatly improves production efficiency and saves cost;

6. The transmission system leases chain drive, adopts two-stage deceleration to prevent misalignment, avoid product wasting; computer system adopts imported electrical appliances with stable work performance , equipped with manual operation procedures with high degree of automation. This machine equipped with the largest worktable area in Asia.

Technical parameter

Outline dimension | 12500mm x2100mm x1700mm |

Bed dimension | 3000mm x1300mm |

Maximum machining height | 60mm |

Total power | 45KW |

Total weight | 4T |

vacuum degree | ≤-0.095Mpa |

Electrical component list

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1 | 1 | Chint | ||||

3 | ammeter | 85L1 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

How it works

v Preheating equipment

v Put product on the workbench

v Pull the PVC membrane and cover cabinet door

v Cutting pvc film

v Enter the machine

v Vacuum plus negative pressure

v Release of negative pressure

v Workbench out

v Trimming

v Work end

This process is done automatically by one click

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance