- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 9 Author: Site Editor Publish Time: 2021-03-23 Origin: Site

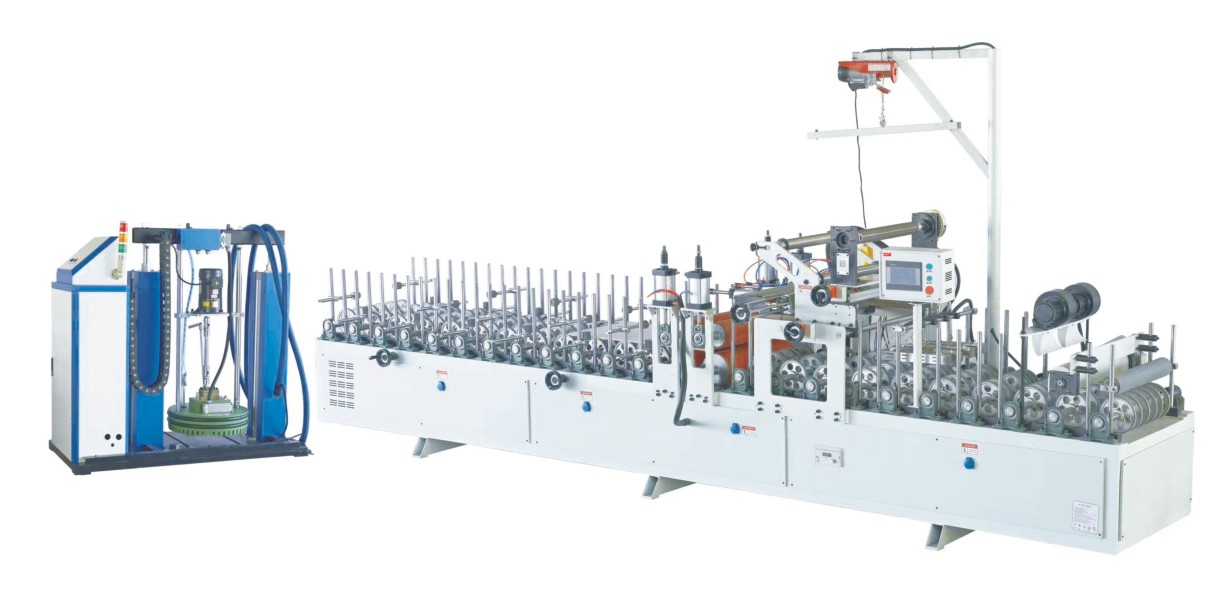

The coating machine is suitable for the production of PVC, decorative paint paper and solid wood veneer on the surface of various lines such as wood, aluminum-plastic profiles, and foam materials. Before the coating machine is used, it is necessary to adjust the profile positioning, pressing wheel, diaphragm, and glue application.

How to debug the coating machine

1. Profile positioning adjustment

Take a fabricated profile. The requirements: it should not be bent or twisted, and put it on the bed conveyor wheel. Adjust the distance between the two rows of conveyor wheels according to the profile width, shape and covering requirements; adjust the ruler and The width and height of the platform make it suitable for the wrapping requirements of the profile; guide wheels on both sides are installed to make the profile and the conveying wheel parallel.

2. Installation and adjustment of the pressure roller

Install and adjust the small pressing wheel according to the profile surface profile, generally select the profile center line or cross section, the highest point or lowest point of the main profile curve, and transition and roll along the profile line point by point. The profile and the diaphragm are compounded together. The installation of the small pressing wheel should balance the force of the line, and proceed at the same time. There is a pressing wheel on the top, and a supporting wheel must be installed at the bottom to balance the line up, down, left, and right. Otherwise, there will be unrealistic phenomena at the line joints. The large plane can be rolled gradually from the center to the two sides with a small pressing wheel, and the small pressing wheel needs to gradually turn the angle 3 times at the 90° corner. For lines with complex shapes, the small pressing wheels need to be arranged naturally and cannot be forced to form. Especially the pasting of decorative paper should be more natural and smooth.

3. Diaphragm installation and glue adjustment

Install the cut film on the film hanging shaft, adjust the position, lift up the glue box, pass the film through the upper film guide roller, pass through the gap at the bottom of the glue box, add glue to the glue box, pull off the inclined iron, The distance is slightly narrower than the width of the diaphragm. Adjust the screws on both sides of the front end of the glue box to control the thickness of the glue. The thickness of the glue depends on the type of glue, generally 50-100 grams of glue is used per square meter.

How to operate the cladding machine correctly

1. Turn on the main power supply, power on the control cabinet, control the barrel up button with both hands to make the coating machine run to the "+90º" feeding position.

2. Use the crane to carry out the feeding operation according to the technological requirements.

3. Control the lowering button of the barrel with both hands to make the coating barrel run to the "+25º" coating position, and start the rotating button of the coating machine to rotate the coating barrel.

4. Set the heating temperature of the coating machine, control the temperature of the inner wall of the coating barrel to be ≤65°C, start heating, and heat the coating barrel.

5. In accordance with the process regulations, add additives for insulation coating.

6. After the powder is completely dried, turn off the heating power and control the barrel down button with both hands to make the coated barrel run to the "-40º" unloading position for unloading, and keep the coated barrel rotating when unloading.

7. When the temperature of the inner wall of the barrel is less than or equal to 40°C, stop the rotation of the coated barrel, turn off the main power supply and wait for the next operation.