- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 115 Author: liya Publish Time: 2024-11-20 Origin: Site

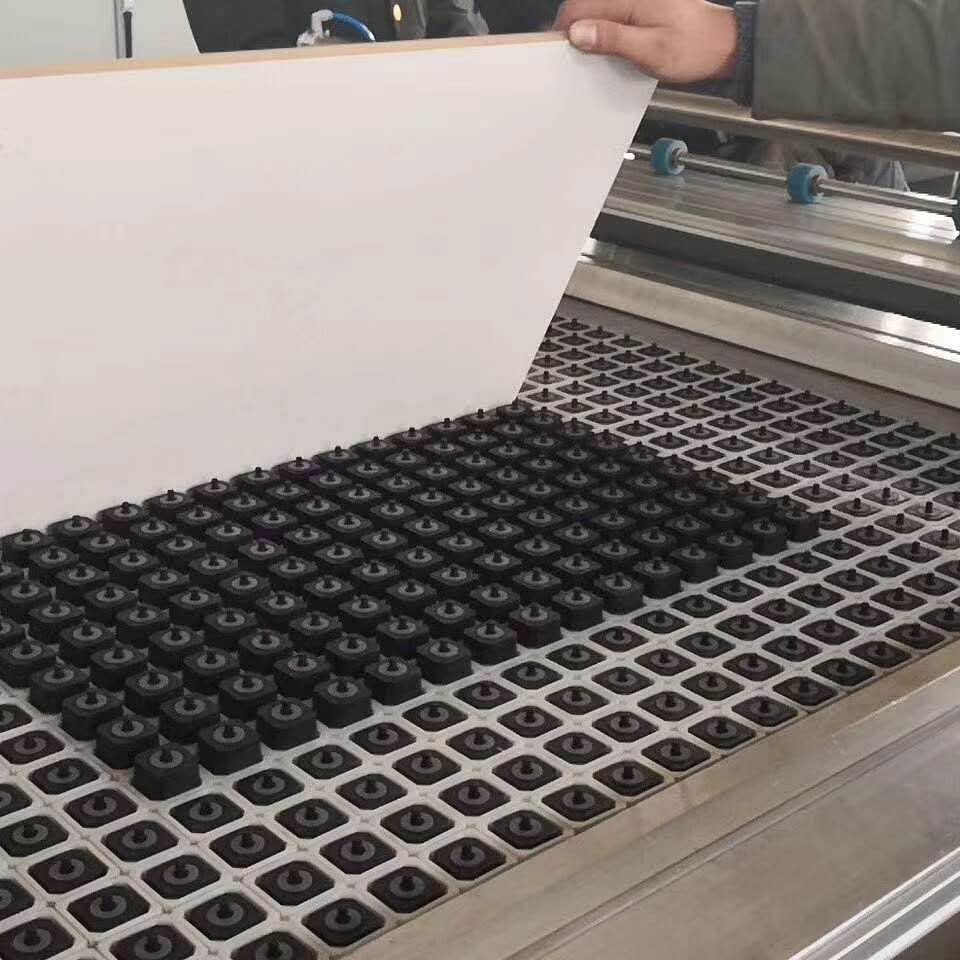

The difference and advantages of the top block of our mechanical structure principle and electronic scanning:

1. Our pin workbench is a gravity sensing system, purely mechanical principle, other manufacturers work on the principle of electronic cooperation with mechanical structure, whether it is Taian or Wemhoner. This workbench has some drawbacks

2. Affected by temperature, as the equipment works for a long time, when the temperature reaches 50-60 degrees, the workbench will be deformed through thermal expansion and contraction, which will cause misoperation of the top block. Why? Because the workbench adopts the structure of infrared radiation to drive the electromagnet or the cylinder to lift or reset the top block to drive the top block to bend or stand upright.

The workbench is covered with a number of small holes. Whether there is a workpiece on the workbench is determined by whether the small holes of the workbench are transparent. When the workbench is affected by thermal expansion and contraction, the light source will be deformed due to the workbench, and it will be different from the light source in the small holes around the top block. If it does not correspond, it will be blocked from light, and then mistakenly think that there is a workpiece here, then it will be jacked up by misoperation.

3. Dust, dust is also a factor that affects misoperation. If dust falls on the light source, it will affect the transmission of light, and misoperation will also occur. There are no furniture factories without dust, so you must work on the workbench several times. To blow soot, blow the top block. Waste time and affect work efficiency.

4. In order to reduce this kind of misoperation, manufacturers usually use thin aluminum plates while reducing costs. In order to allow light to pass through easily, 4-5-6mm thick aluminum plates are used. Wemhoner uses 5mm aluminum plates for this reason. If the aluminum plate If the thickness is reduced, the stability of the machine will decrease, the stability will decrease, the work will be easily deformed, and it will also be misoperated. Therefore, all manufacturers will adopt a compromise method in this regard. The early misoperation is low, so as the equipment is used longer. , the failure rate will increase.

The last item, in terms of maintenance cost, if the top block is broken, we only need to remove it, replace it with a new one, and press it on. Other manufacturers can do the same, but when working, the top block is easy The reason for being sucked out is due to the design of the device itself, and also the disadvantage of the electronic cooperation with the mechanical structure. If you do not want to be sucked out, then the device needs to be modified in a series of places, which is impossible.

Our aluminum plates are purely imported from Germany and never made in China, the reason is that the stability of the machine determines the quality of the product. We use 10 thick aluminum plates. The cost is about 50,000 RMB.

For more information contact me please

Liya Liu WhatsApp:+8618204035885

Liaoning ZHT machinery Equipment Company LTD