- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

HBDL-1600

ZHT

HBDL-1600

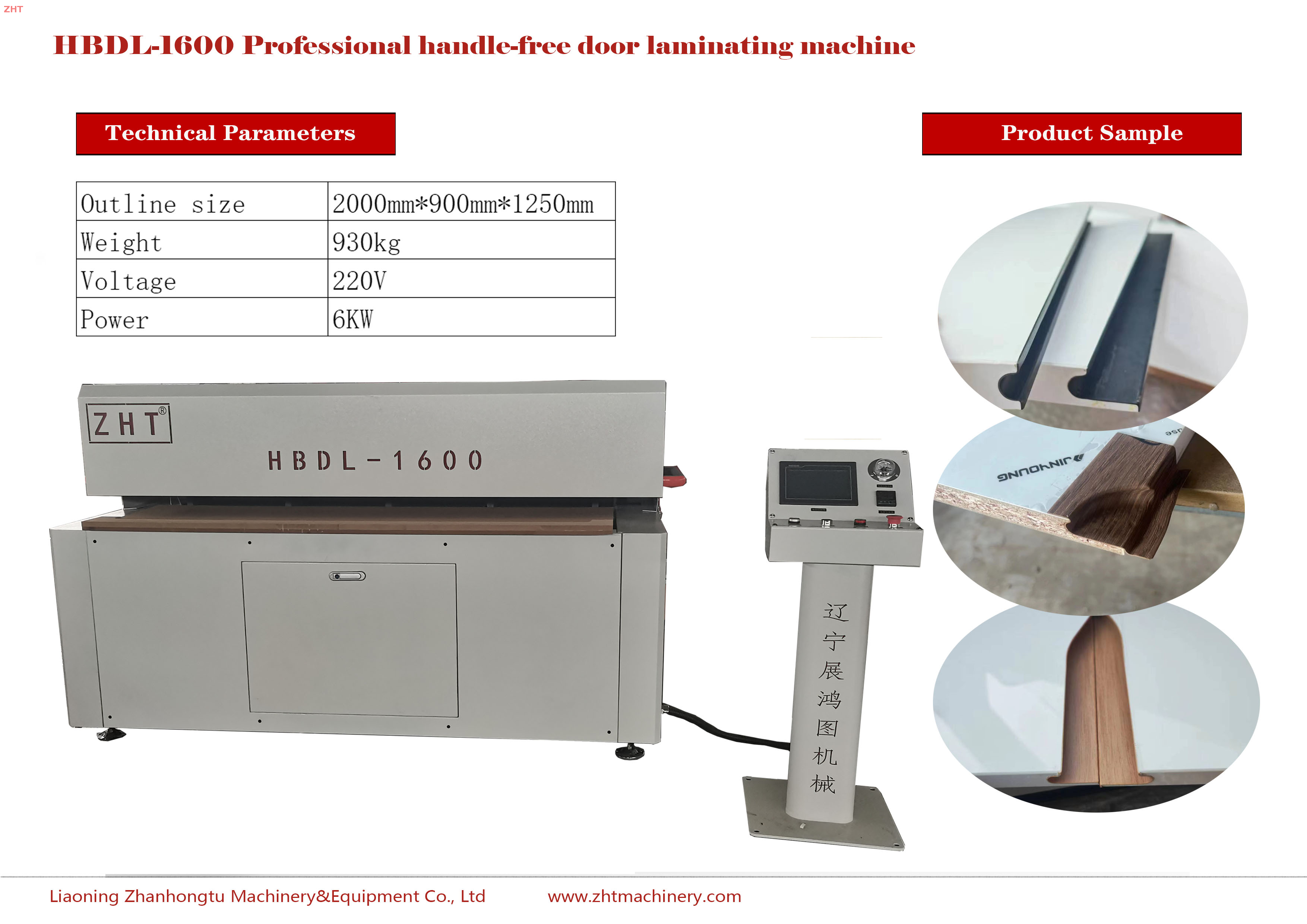

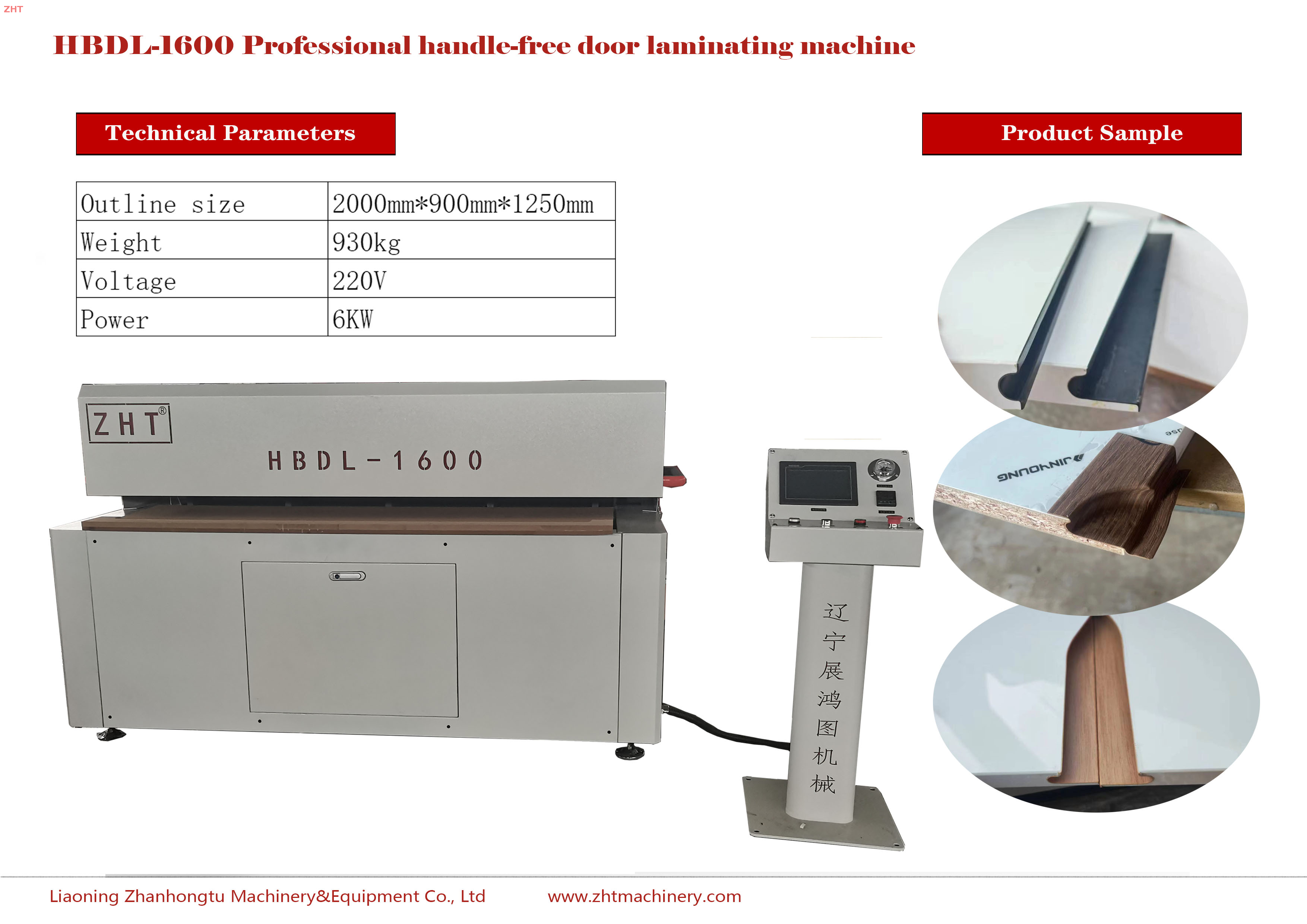

HBDL-1600Professional handle-free door laminating machine

"Non-Handle Positive and Negative Pressure Laminating Machine" Introduction

The non-handle positive and negative pressure laminating machine is an efficient and advanced device designed for the seamless lamination of printed materials with pre-coated plastic film. This machine incorporates cutting-edge technology and features the following characteristics:

**1. Simple and Efficient Structure:**

The non-handle positive and negative pressure laminating machine consists of four main parts: film unwinding, automatic input of printed materials, hot pressing and laminating, and automatic winding. Its structure is more compact compared to traditional devices, making operation simpler. Moreover, it eliminates the need for adhesive coating and drying, leading to increased efficiency.

**2. High Production Flexibility:**

Designed with production flexibility in mind, this machine can be instantly operated, catering to various laminating machines, composite machines, and sealing machines with thermal pressing capabilities. The lamination of pre-coated film and paper printed materials is achieved through a straightforward process of hot pressing.

**3. Automatic Conveying with Precision Control:**

Equipped with an automatic conveying mechanism, the machine ensures that printed materials are transported without overlap and enter the laminating section at equal intervals. Control is achieved through pneumatic or friction methods, ensuring accurate and high-precision transmission suitable for printed materials of various sizes.

**4. Integrated Design for Lamination and Calendering:**

The laminating section of the non-handle positive and negative pressure laminating machine includes the laminating roller group and the calendering roller group. The laminating roller group consists of heated pressure rollers and silicone pressure rollers, utilizing an advanced adjustment mechanism for seamless control. The calendering roller group, through secondary pressing, significantly enhances the surface brightness and bonding strength of the laminated printed materials.

**5. Advanced Computer Control System:**

Featuring a computer control system with a microprocessor, the machine incorporates hardware components such as the mainboard, digital keypad, optical isolation board, power board, and stepper motor power driver board. This system enables intelligent monitoring and precise control of the entire laminating process.

The non-handle positive and negative pressure laminating machine, with its advanced technology and high efficiency, has become a crucial asset in the modern field of laminating printed materials, bringing greater convenience and benefits to the production process.

![]()

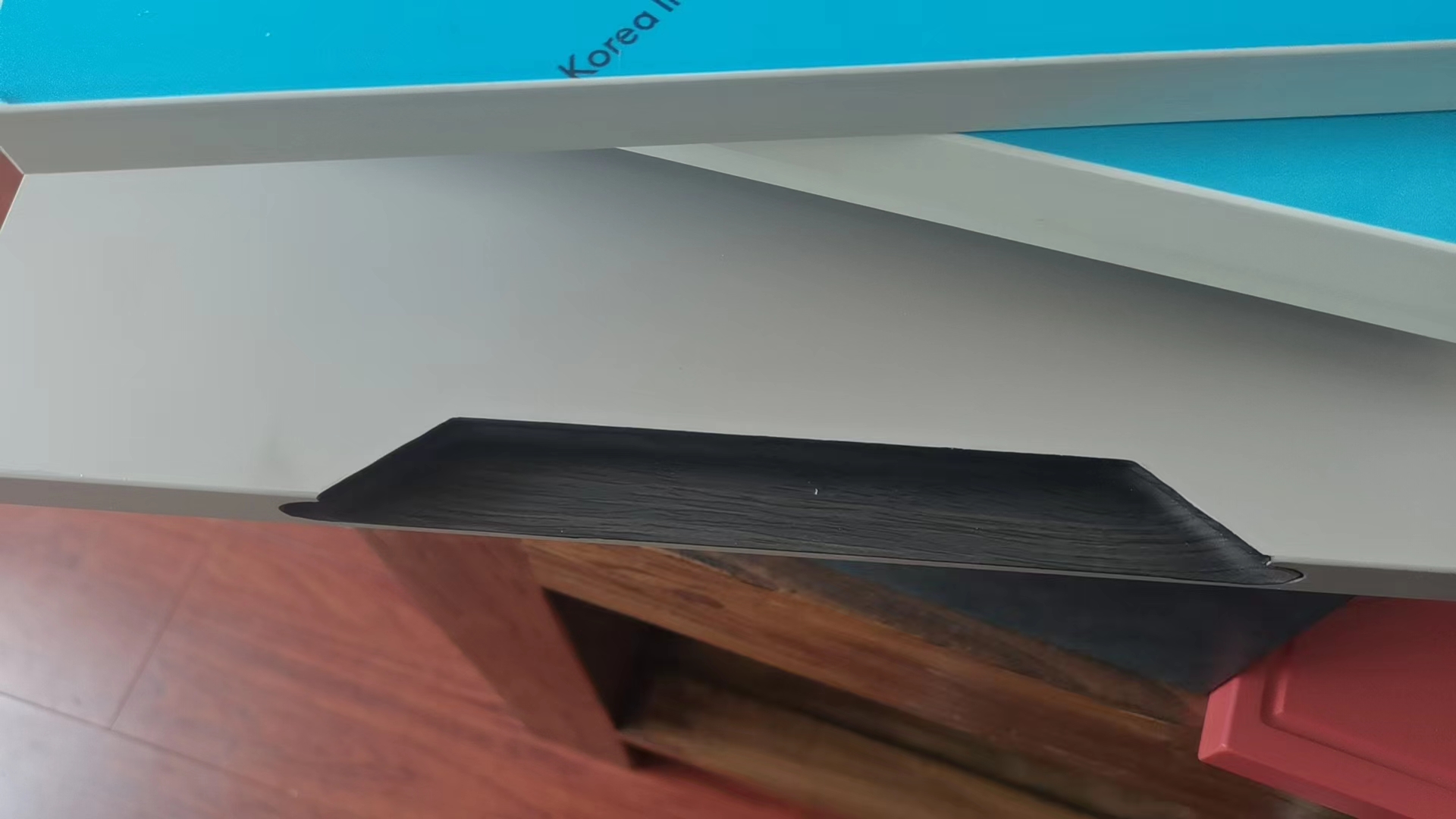

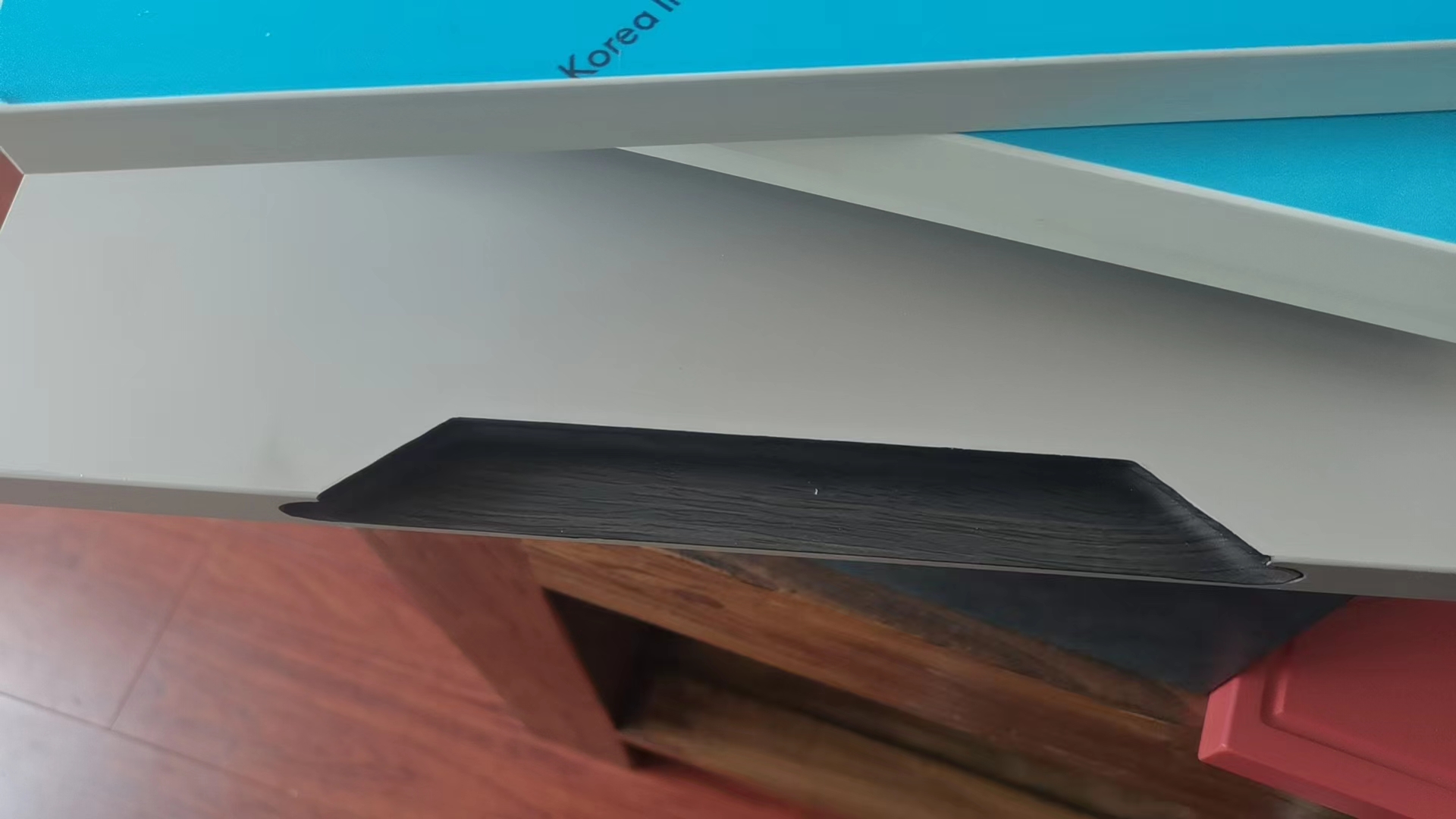

Finished effect

Quality and Service are most important things for us

If you have any problem,please let us know

HBDL-1600Professional handle-free door laminating machine

"Non-Handle Positive and Negative Pressure Laminating Machine" Introduction

The non-handle positive and negative pressure laminating machine is an efficient and advanced device designed for the seamless lamination of printed materials with pre-coated plastic film. This machine incorporates cutting-edge technology and features the following characteristics:

**1. Simple and Efficient Structure:**

The non-handle positive and negative pressure laminating machine consists of four main parts: film unwinding, automatic input of printed materials, hot pressing and laminating, and automatic winding. Its structure is more compact compared to traditional devices, making operation simpler. Moreover, it eliminates the need for adhesive coating and drying, leading to increased efficiency.

**2. High Production Flexibility:**

Designed with production flexibility in mind, this machine can be instantly operated, catering to various laminating machines, composite machines, and sealing machines with thermal pressing capabilities. The lamination of pre-coated film and paper printed materials is achieved through a straightforward process of hot pressing.

**3. Automatic Conveying with Precision Control:**

Equipped with an automatic conveying mechanism, the machine ensures that printed materials are transported without overlap and enter the laminating section at equal intervals. Control is achieved through pneumatic or friction methods, ensuring accurate and high-precision transmission suitable for printed materials of various sizes.

**4. Integrated Design for Lamination and Calendering:**

The laminating section of the non-handle positive and negative pressure laminating machine includes the laminating roller group and the calendering roller group. The laminating roller group consists of heated pressure rollers and silicone pressure rollers, utilizing an advanced adjustment mechanism for seamless control. The calendering roller group, through secondary pressing, significantly enhances the surface brightness and bonding strength of the laminated printed materials.

**5. Advanced Computer Control System:**

Featuring a computer control system with a microprocessor, the machine incorporates hardware components such as the mainboard, digital keypad, optical isolation board, power board, and stepper motor power driver board. This system enables intelligent monitoring and precise control of the entire laminating process.

The non-handle positive and negative pressure laminating machine, with its advanced technology and high efficiency, has become a crucial asset in the modern field of laminating printed materials, bringing greater convenience and benefits to the production process.

![]()

Finished effect

Quality and Service are most important things for us

If you have any problem,please let us know