- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TM-2480M

ZHT

TM-2480M

Specification:

Model: TM2480M

Dimension: 10300MM×1920MM×1730MM

Worktable size: 2550(2350)MM×1150MM×40MM

Maximum working surface: 2550(2350) MM×1150MM×40MM

Maximum height of workpiece: 60MM

Total power: 15KW

Actual power consumption: 5KW

Total weight: 2000(2500)KG

Vacuum level: ≥ -0.095Mpa to -0.08Mpa

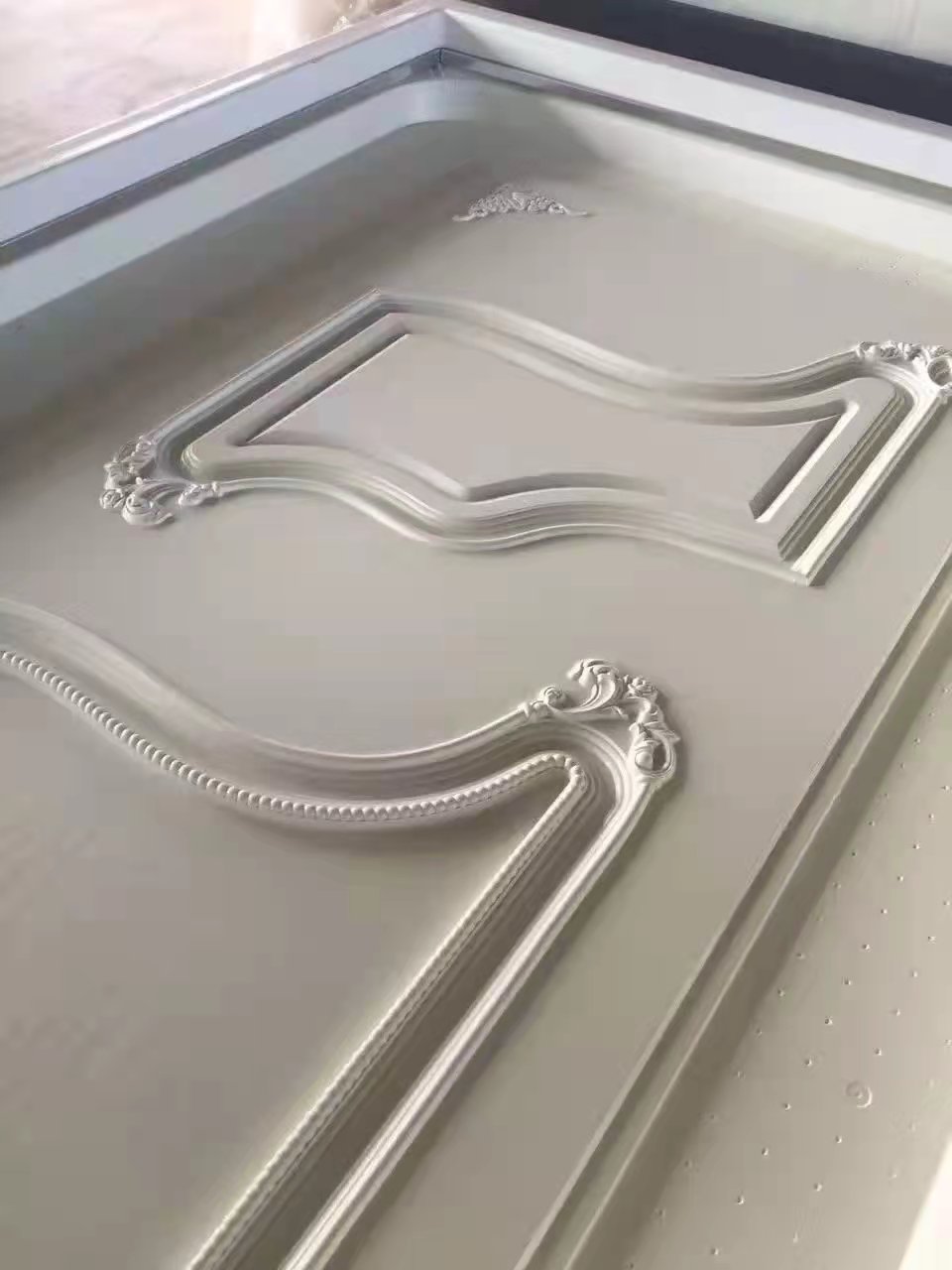

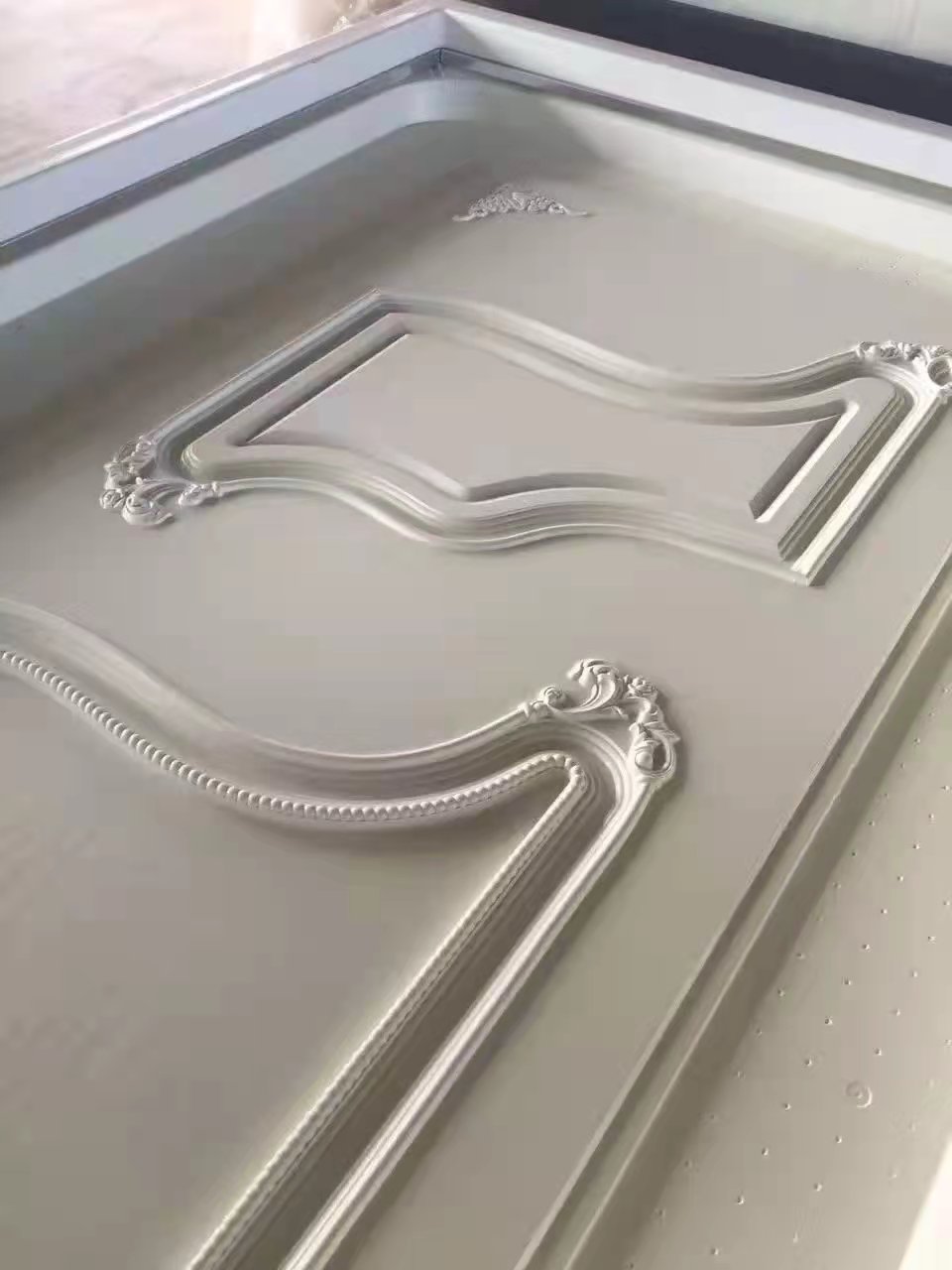

Description:TM series vacuum laminating machine is an economical and practical equipment designed for laminating various PVC films on different substrates, such as imitation wood, stone, leather, etc. The machine utilizes German vacuum technology, features a compact design, and is available in manual, semi-automatic, and automatic models with different table configurations.

**Workpiece Processing Technology:**

1. Surface preparation: Sand the workpiece surface to remove wood chips and residues.If you have purchase needs please contact AllisonHao

2. Edges and corners: Recommend rounded or beveled edges for better lamination.

3. Glue spraying: Ensure uniform and complete coverage on the workpiece.

4. Drying: The glued workpiece should be dried before the laminating process.

5. Workpiece placement: Maintain a suitable distance to prevent film rupture during suction coating.

6. Avoid sharp workpieces: Prevent damage to the PVC film during operation.

7. Padding: Use a pad with good air permeability and proper thickness.

8. Film repair: Seal any holes with transparent tape, and use an electric hair dryer for heat repair if needed.

9. Trim excess film: Cut off excess PVC film with a paper cutter after processing.

**Equipment Maintenance Requirements:**

1. Keep the workbench clean to prevent dust.

2. Ensure the vacuum pipeline is unblocked.

3. Check and replenish vacuum pump oil regularly.

4. Lubricate the workbench pressing handle regularly.

5. Operate within the machine's design indicators for safety.

6. Consult the factory before using non-factory provided maintenance parts.

**Note:** Use special oil for vacuum pumps, such as vacuum No. 1 oil for belt pumps and N68# oil for direct-coupled pumps.

Specification:

Model: TM2480M

Dimension: 10300MM×1920MM×1730MM

Worktable size: 2550(2350)MM×1150MM×40MM

Maximum working surface: 2550(2350) MM×1150MM×40MM

Maximum height of workpiece: 60MM

Total power: 15KW

Actual power consumption: 5KW

Total weight: 2000(2500)KG

Vacuum level: ≥ -0.095Mpa to -0.08Mpa

Description:TM series vacuum laminating machine is an economical and practical equipment designed for laminating various PVC films on different substrates, such as imitation wood, stone, leather, etc. The machine utilizes German vacuum technology, features a compact design, and is available in manual, semi-automatic, and automatic models with different table configurations.

**Workpiece Processing Technology:**

1. Surface preparation: Sand the workpiece surface to remove wood chips and residues.If you have purchase needs please contact AllisonHao

2. Edges and corners: Recommend rounded or beveled edges for better lamination.

3. Glue spraying: Ensure uniform and complete coverage on the workpiece.

4. Drying: The glued workpiece should be dried before the laminating process.

5. Workpiece placement: Maintain a suitable distance to prevent film rupture during suction coating.

6. Avoid sharp workpieces: Prevent damage to the PVC film during operation.

7. Padding: Use a pad with good air permeability and proper thickness.

8. Film repair: Seal any holes with transparent tape, and use an electric hair dryer for heat repair if needed.

9. Trim excess film: Cut off excess PVC film with a paper cutter after processing.

**Equipment Maintenance Requirements:**

1. Keep the workbench clean to prevent dust.

2. Ensure the vacuum pipeline is unblocked.

3. Check and replenish vacuum pump oil regularly.

4. Lubricate the workbench pressing handle regularly.

5. Operate within the machine's design indicators for safety.

6. Consult the factory before using non-factory provided maintenance parts.

**Note:** Use special oil for vacuum pumps, such as vacuum No. 1 oil for belt pumps and N68# oil for direct-coupled pumps.