- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 10 Author: Site Editor Publish Time: 2020-02-21 Origin: Site

The difference between positive & negative pressure laminators with and without PIN system:

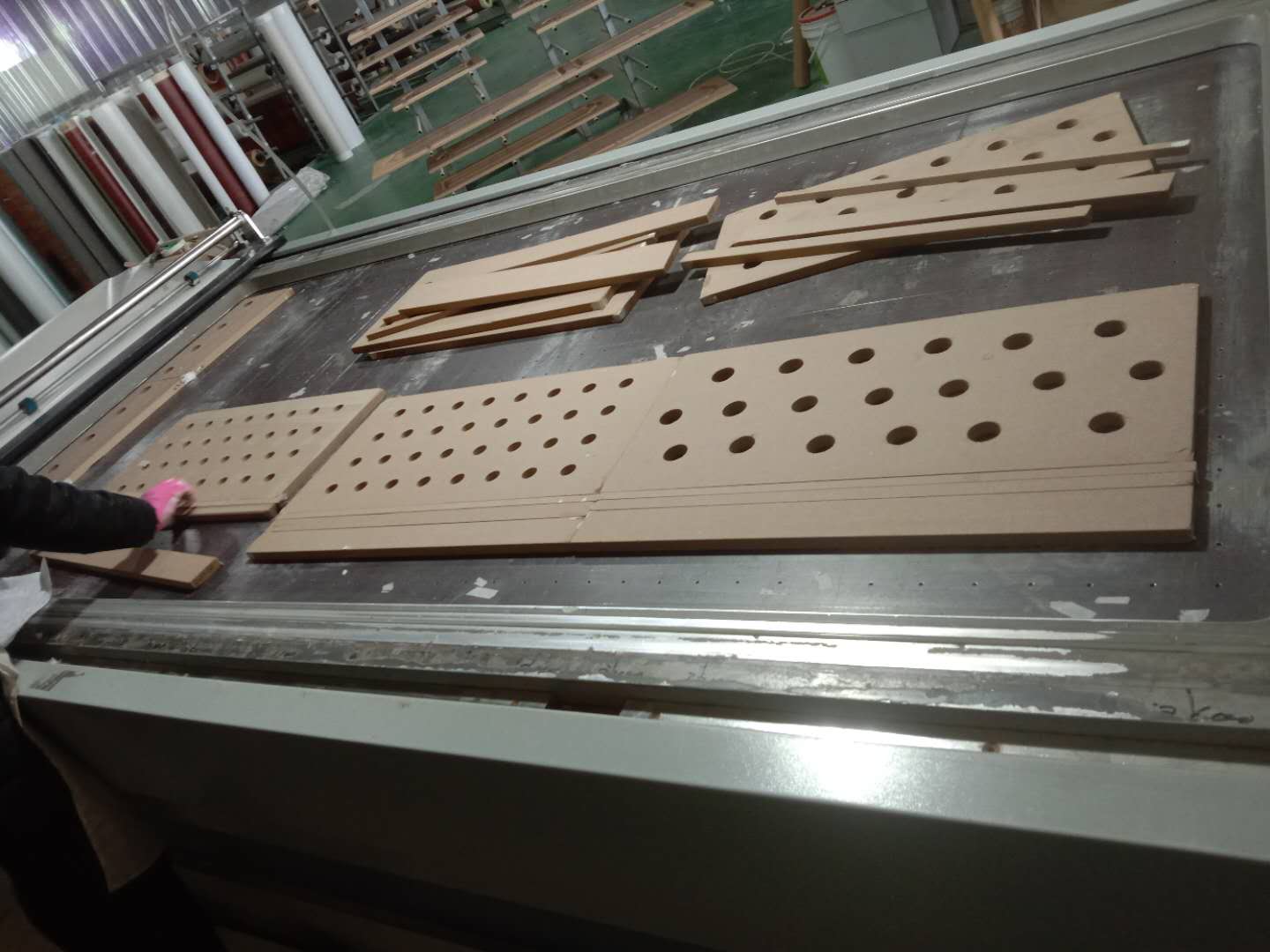

1. Positive-negative pressure laminating machine without thimble system: When laminating wood boards, it is necessary to use a pad to assist the processing. When processing products of different sizes and shapes, a special size and shape pad needs to be customized. , Increase costs and reduce processing efficiency. When laminating, the underboards of cabinet boards, wardrobe doors, and wooden doors are frequently replaced, which is labor-intensive, labor-intensive, time-consuming, and complicated.

2. Positive and negative pressure laminating machine with thimble system: The thimble system is a gravity sensing system with high degree of automation, and the laminating operation is not limited by the shape and size of the workpiece. It does not need a pad, saving costs and manpower, and increasing work efficiency.

The positive and negative pressure laminator is sealed with a silicone plate, which forms a stronger air pressure than the simple negative pressure on the top and bottom of the silicone plate, and blister the PVC onto the plate. Because there is an additional positive pressure, the pressure of the positive and negative pressure is greater, so the pressure of the positive and negative pressure vacuum laminator will be more firm.

Traditional positive and negative pressure laminators need to be placed on the bottom of the workpiece, which is slightly smaller than the size of the workpiece to be processed during operation. Put the workpiece up to make the workpiece film more in place (similar to plastic wrap) ), The production of pads requires higher dimensional accuracy of the pads, and requires higher operating requirements for workers. It belongs to skilled trades and has higher wages, and it requires more space to store these pads.

Based on this industry problem, ZHT has carried out technical innovations and invented an automatic ejector system and applied for a patent. This technology is also known in the industry as a padless / automatic ejector block / PIN system.

The PIN system does not need to use a wooden board as the backing plate. Using the wooden board as the backing plate requires the size of the backing plate to be the same as the workpiece under pressure. And the storage of these boards requires a lot of space, and this problem does not exist with the ejector system.

Our automatic PIN system is equivalent to replacing the traditional padding process. Using the principle of gravity induction, the workpiece is automatically jacked up by sensing the position of the workpiece. After placing the workpiece, the film can be pulled and ejected to the inside. The workpiece can be processed as long as it is square (trapezoidal, circular workpiece is not supported for the time being), and workpieces with arc can also be processed.