- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 9 Author: Site Editor Publish Time: 2022-11-10 Origin: Site

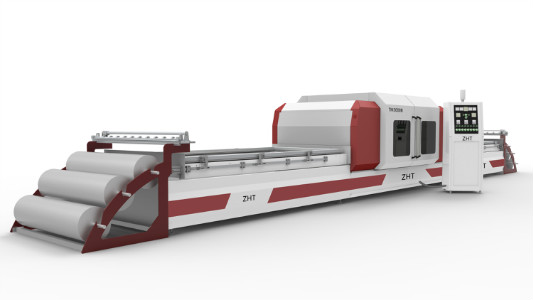

How to choose vacuum membrane press machine ?

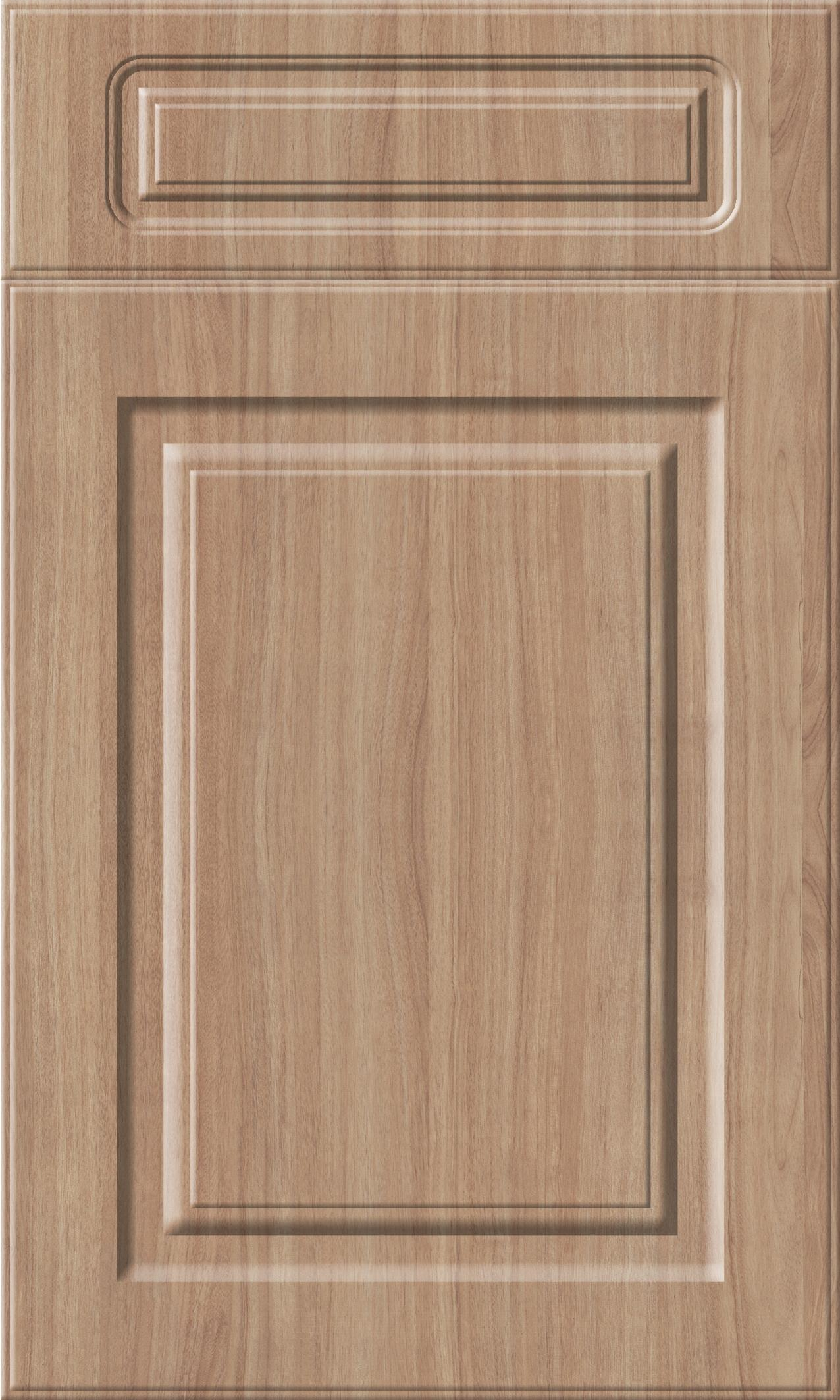

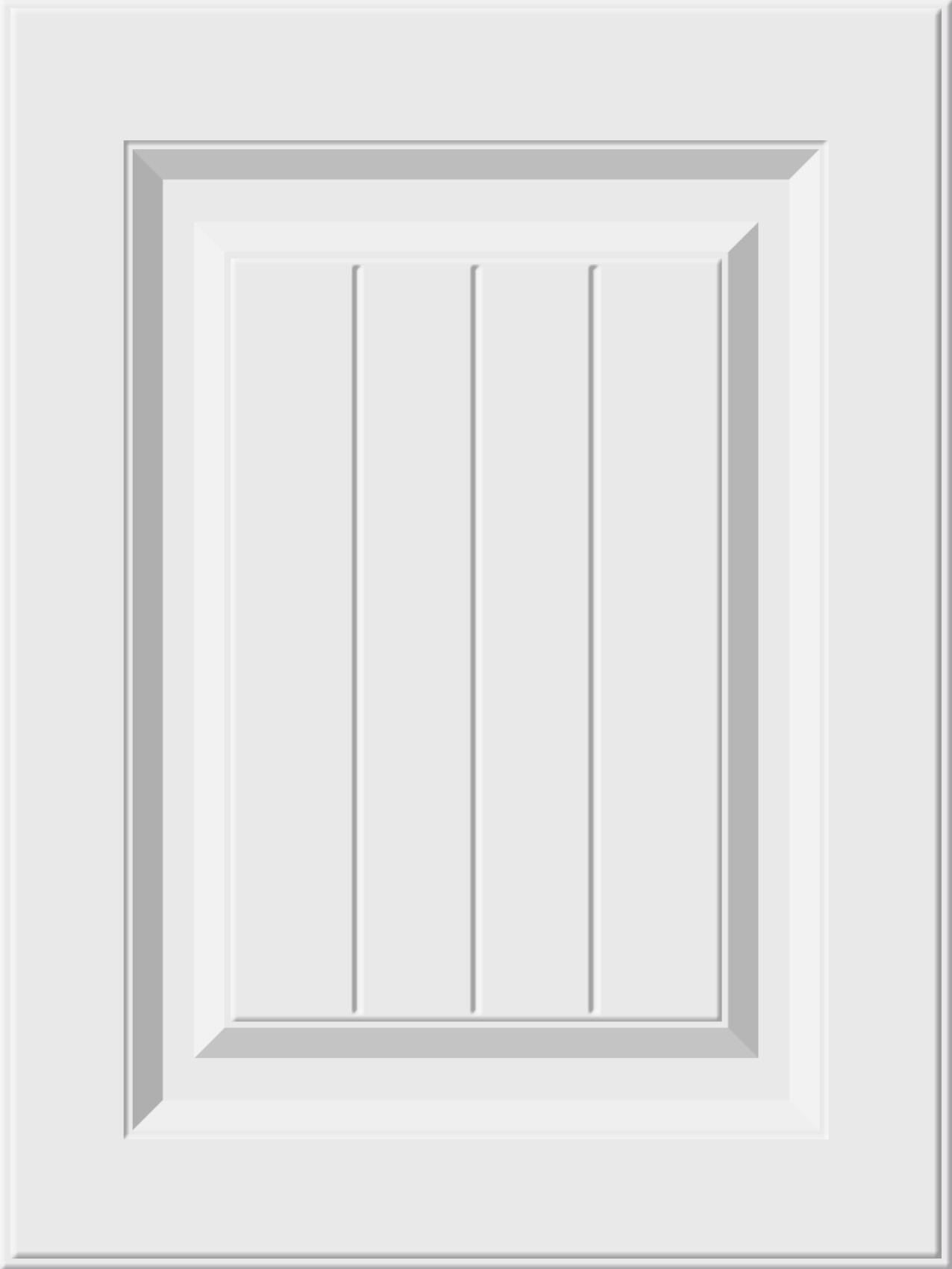

1 First of all, according to your product type, it is cabinet door, wardrobe door or interior door.

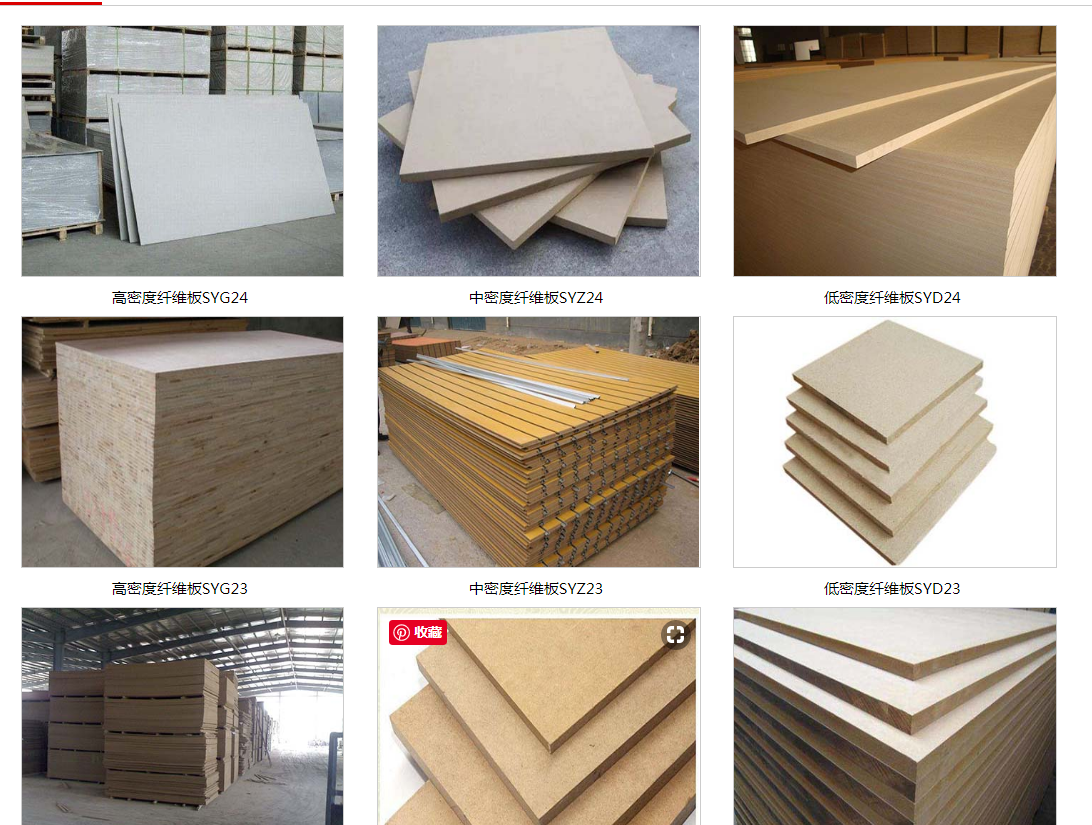

2 According to the material of the door panel, it is MDF, or other wooden material.

3 Output, according to your own orders, choose the equipment with the appropriate output.

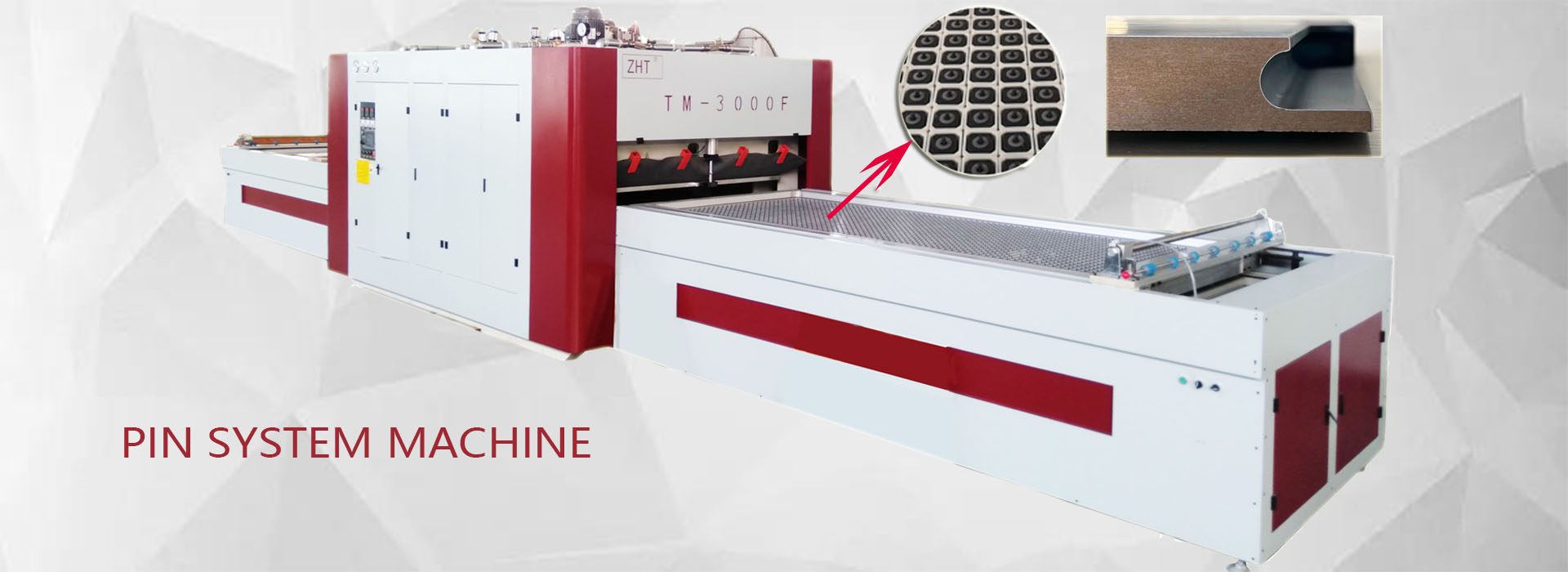

4 Laminating machine, divided into negative pressure machine, positive and negative pressure machine, positive and negative pressure machine with pin, positive and negative pressure machine with pin with replica, and fully automatic equipment with three trays.

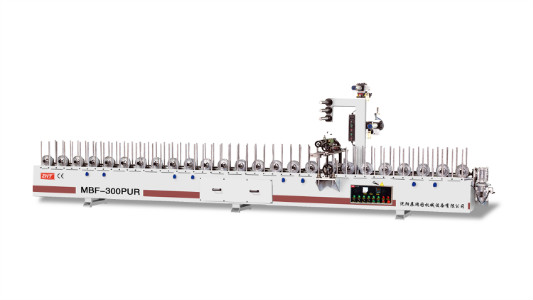

profile coating machine negative press machine positive and negative press machine

upper press machine with pin system automatic three trays machine with pin system

Many accessories can be purchased, such as whether it is equipped with a pin table, whether it needs an automatic film pulling system, whether it is equipped with a flip fabric rack, whether it is equipped with a copy plate, etc.

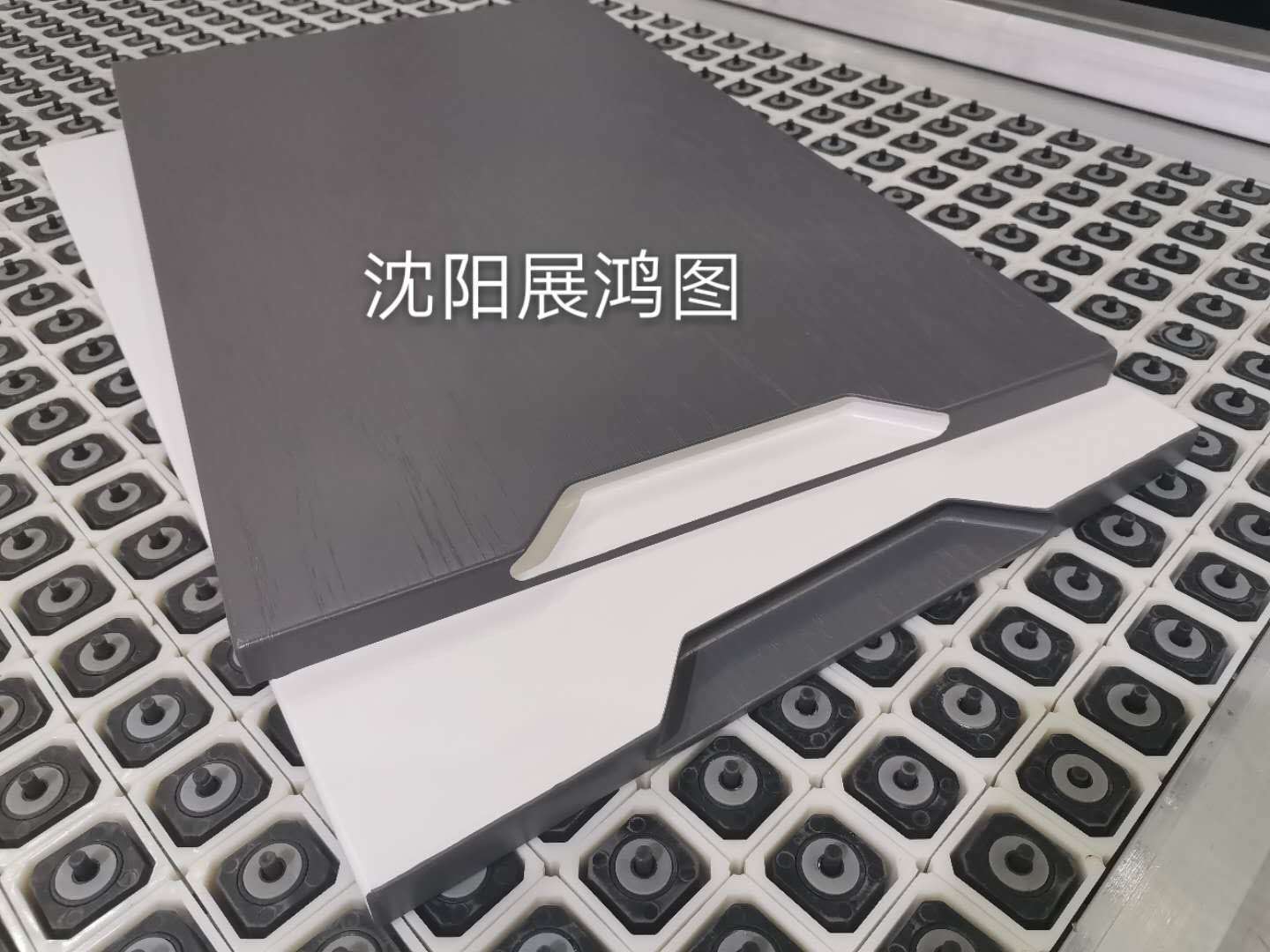

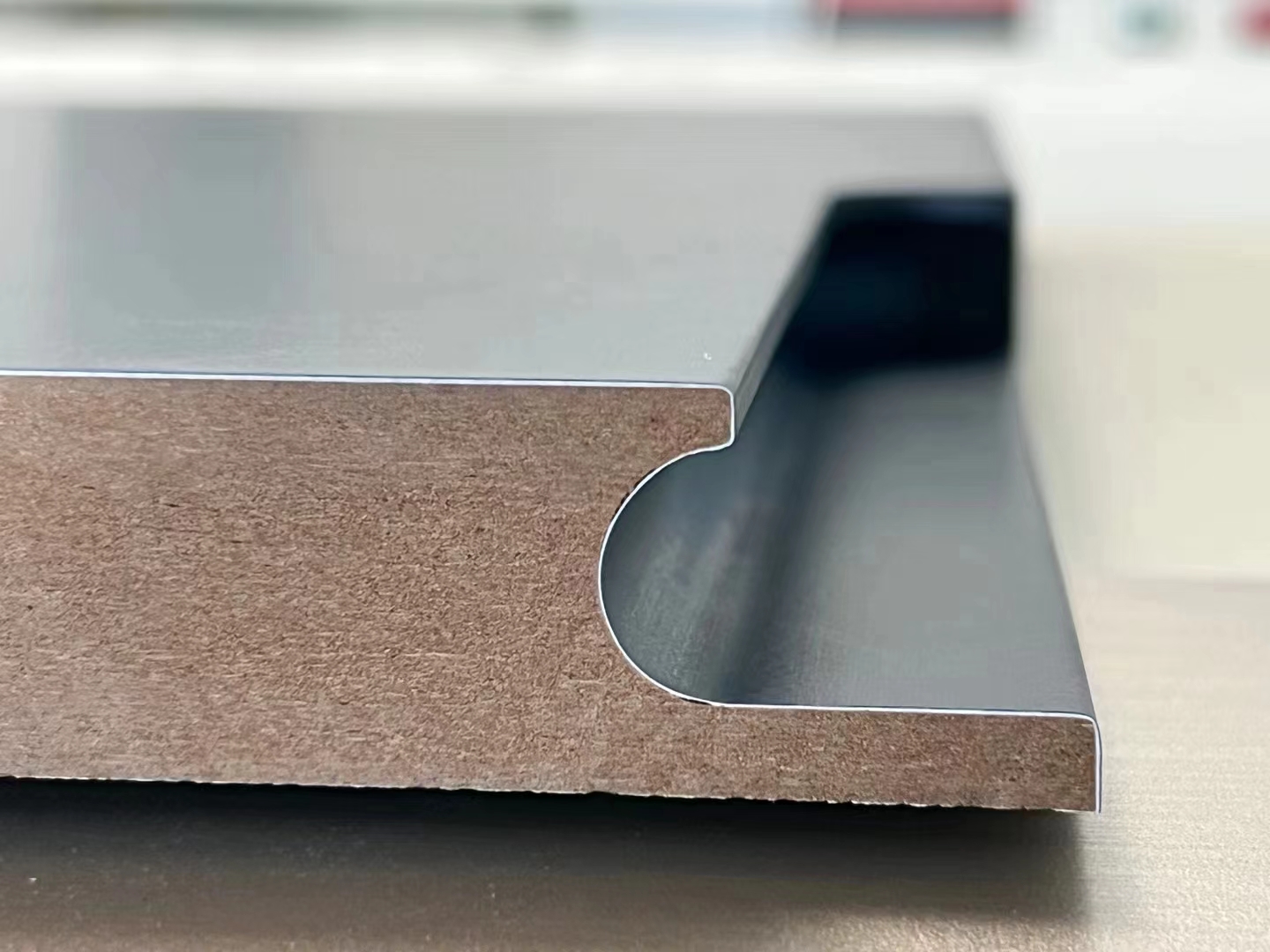

5 The negative pressure machine can make most of the door panel shapes, but it cannot make handle-free or high-gloss workpieces, positive and negative pressure equipment, because the heating system is different and there is upward pressure, the workpiece can be done in place, including high-gloss, no-draw hand parts.

6 The device with pin is a device that does not need to place a backing plate, gravity induction system, the worktable will automatically rise according to the size of the placed workpiece, the work efficiency is fast, and the output is high.

7. The equipment with a copy plate will still increase the output, because it is not necessary to trim the workpiece on the worktable, and it will be turned over to another worktable for trimming, which will not affect the continued placement of the workpiece. Improve efficiency

8 The equipment with three pallets is three pallets circulating work, making full use of the working time, the equipment has no working gap, making full use of the equipment work. At the same time, it is equipped with an automatic turning fabric rack and automatic film pulling system, which will make the work more efficient.

9 According to the specific situation of your factory, you can choose the appropriate equipment. At the same time, choose not only the parameters or accessories. Good accessories can improve the stability of the equipment, and can not determine whether the equipment can make good products. If you can bring your own piece The board, let the workers make it on the spot, you can let the workers make a handle-free door panel, and cut it on the spot to check whether it is in place.

10 When workers operate on-site, they should pay attention to the parameters and the condition of the pressure gauge to see how much pressure can make such an effect.

11 Look at the power of the equipment at the same time, pay attention to the total power and the actual power. Generally, the actual power is one-third of the total power, which determines how much the electricity bill will be in the future.

12 Heating system, electric heating or oil heating, if the oil heating equipment is used for a long time, there will be problems such as uneven heating, long preheating time, high energy consumption, electric heating, uniform heating, short preheating time, especially in winter, Low energy consumption.

13 Vacuum pumps, hydraulic cylinders, electrical parts, transmission systems, etc., use high-quality accessories. Pay attention to the brand.