- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2023-03-15 Origin: Site

Unpainted wooden door production process and required equipment

1. PVC film paint-free door (surface material: PP, PE, PVC, PETG)

2. White stubble wooden door (both original wooden door)

3. CPL wooden door: characterized by high hardness

4. Painted paper door

5. Ecological doors generally have aluminum alloy edge banding

Note: HDF is generally used, and there are two sizes: (1) 2.1m*2.5m*8mm or (2) 1.22m*2.44m*8mm

1. Equipment required for door skin process

1. Electronic cutting saw

2. Machining center for engraving door skin patterns

3. Grinding machine

4. Glue spraying machine

5. Laminating machine

2. Laminate equipment (L port line and cladding)

1. Sliding table saw or electronic cutting saw

2. Glue applicator (white glue): for multi-layer board lamination

3. Cold press: multi-layer board lamination

4. Slotting options are available: (1) vertical milling feeder; (2) planer; (3) slotting machine.

Note: You can also choose both

5. Edge banding machine: when the edge of the cover board is not cut smoothly, the edge can be flattened

6. Coating machine

7. Cutting machine

Three, close the door

1. Saw: used to cut the width of wooden strips

2. Glue applicator: apply glue to the frame of the door panel

3. Cold press or high frequency press

4. Planer on all sides

5. Punch keyholes and hinges

6. Edge banding machine

7. Wood thread laminating machine

we have laminating machine , coating machine and cutting machine

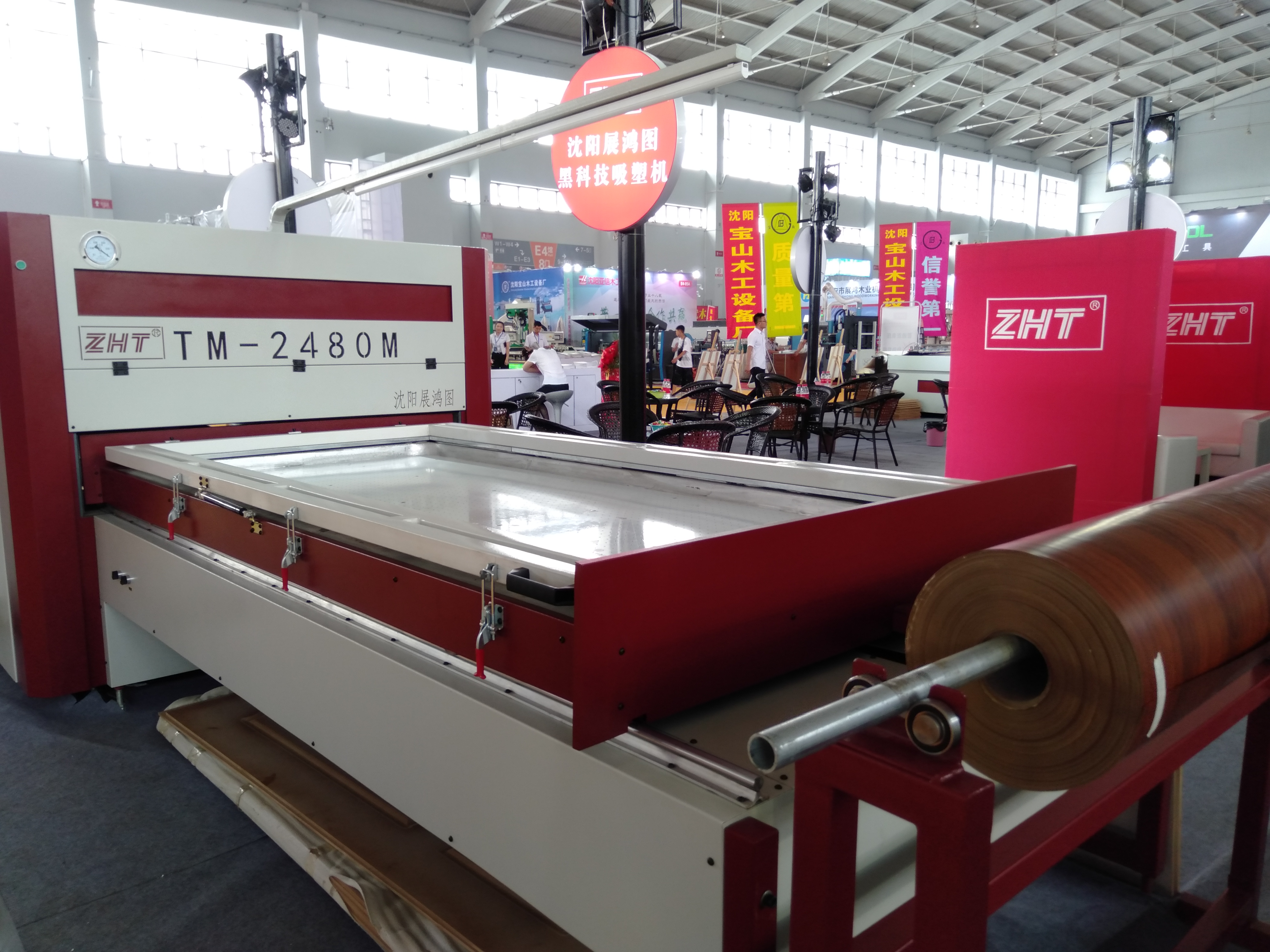

laminating machine for door skin and or door surface .such as TM2480A TM2480M and TM5000

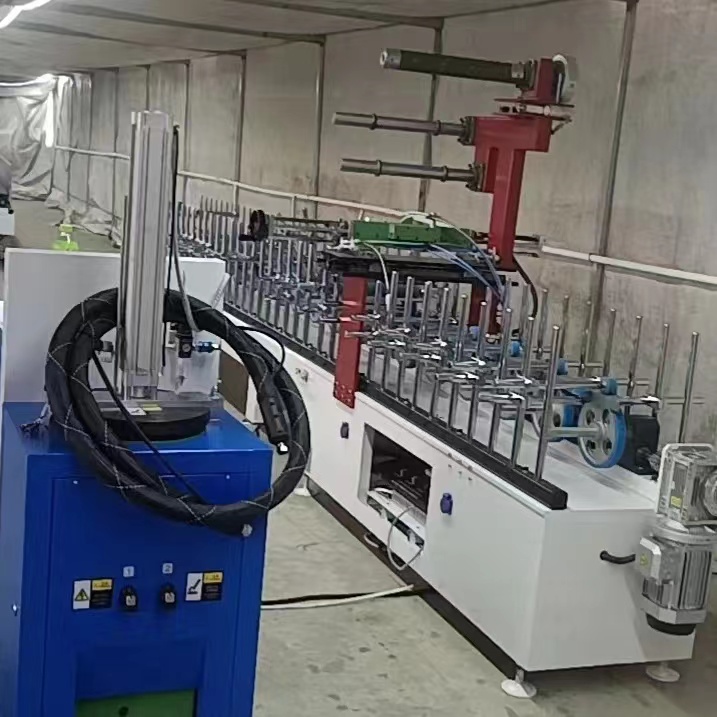

coating machine we have MBF 350 MBF 450 MBF 1300

MBF 350 for door line , L shape , narrow product

MBF 450 FOR door frame

MBF 1300 FOR DOOR SKIN, if your product are all flat surface , you can selelct this machine

cutting pvc film machine is for cut the width of pvc for door line or door frame