- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2022-01-10 Origin: Site

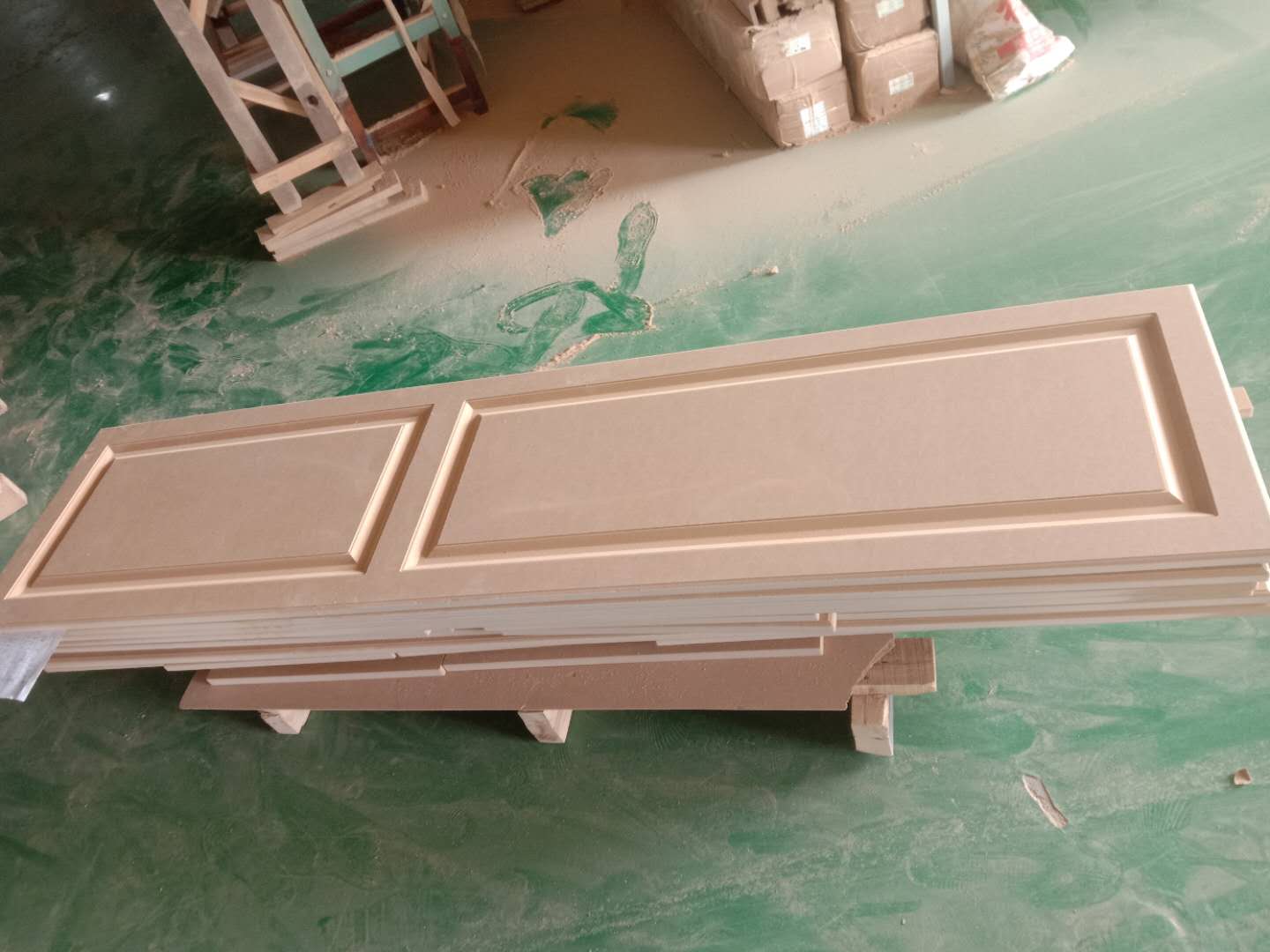

The blister door is an excellent cabinet door, with rich colors and textures, and is scratch-resistant and wear-resistant. It is the more common type of modern cabinet doors.

Grasping the quality of cabinet door panels is also one of the skills for purchasing cabinets. A good cabinet must pass the quality of the door panels. The way to distinguish the quality of plastic cabinet door panels can be seen from four aspects: substrate quality, film quality, surface treatment and workmanship.

1. Substrate quality identification method

The quality of the base material directly determines whether the cabinet door panel has the secondary nail-eating ability, the nail-holding ability, the deformation degree of the finished blister board and the environmental protection performance of the finished blister board. The density of good plastic door panels is different from that of ordinary substrates. The best way to distinguish them is to choose small pieces of the same size and weigh them. The high density plastic door panels are relatively nail-holding. The ability will be better, and the deformation will be smaller.

2. How to identify the quality of the membrane skin

The quality of the film skin directly determines the grade and performance of the finished blister door panel. A good blister film should reach a certain thickness, the film skin should be evenly glued, and the color should be stable. If the thickness of the PVC film is low, it will cause whitening phenomenon and surface orange peel phenomenon when pressing the edges and corners. There is a problem of sheet deformation, but the adhesion and pressure firmness of the PVC film and the substrate cannot be guaranteed. The main problem caused by the uneven back glue of the film skin is that the PVC film skin and the substrate cannot be glued normally, and the PVC film itself cannot be glued and pressed by the glue and the base material through the blister machine. It must be rolled on the back during production. We call it back glue, whether the back glue is uniform or not, and the quality directly affects the adhesive pressure between the PVC film and the substrate. The color problem is the most noticeable problem of the finished blister board, and yellowing is an inevitable problem, but the stability of the PVC surface texture and color must be guaranteed, otherwise it is likely to occur during the normal wiping process. Fading problem.

3. Surface treatment of plastic door panels

Surface treatment is related to the overall image of the finished blister board. If the orange peel phenomenon is serious, the entire door panel looks darker (orange peel refracts light), and the high-gloss blister door panel is very obvious at this point.

4. The workmanship of the plastic door panel

This is the most likely to cause trouble in the process of use. It is mainly reflected in the adsorption at the corners. If there is glue opening, then this piece of plastic cabinet door panel may suffer from water absorption deformation and cracking of the PVC film itself during use. When choosing, you can use your fingernails to dig the part of the PVC film and the board that is glued and pressed. The blister board with good workmanship (including the back glue and the good glue) will not be pulled off with a little force.

What are the advantages and disadvantages of plastic door panels?

1. Advantages of plastic door panels:

Good quality blister door panel base material is not easy to deform, and has good environmental protection performance, delicate appearance, wear resistance, scratch resistance, high temperature resistance, and flame retardant performance.

2. Disadvantages of plastic door panels:

Poor quality blister door panels, the substrate is easy to deform, the appearance is rough, and it is afraid of scratching.

3. Other knowledge:

The thickness of PVC film used for blister door panels is generally 0.15mm-0.45mm. The price imported from Germany is more expensive, followed by products from South Korea, Japan and joint ventures, and the domestic ones are less expensive.

The thickness of the blister door affects the price, so it must be taken into account, and several parameters are given as reference standards: the best blister door in Europe is 18mm thick, and the PVC coating is 0.35mm thick. Generally, the thickness of imported plastic doors is 16-18mm, and the thickness of PVC coating is 0.3-0.35mm. The thickness of the domestic blister door is also 16-18mm, but the quality is not as good as the imported one, and the thickness of the PVC coating is about 0.3.

When choosing doors, we may pay attention to their material, because the performance of the material determines the service life of the product to a certain extent, except for our common wooden doors made of wood and steel made of some stainless steel materials As far as steel doors are concerned, the blister door as an example today may have a better service life and cost-effectiveness. It is a product made of blister materials as raw materials and processed with the inspiration of designers through some complex processes. On the one hand, it can be Satisfy the user's opening and closing needs. On the other hand, they have a glossy surface, easy to clean, and the later use effect is also very good.