- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 6 Author: Site Editor Publish Time: 2019-05-27 Origin: Site

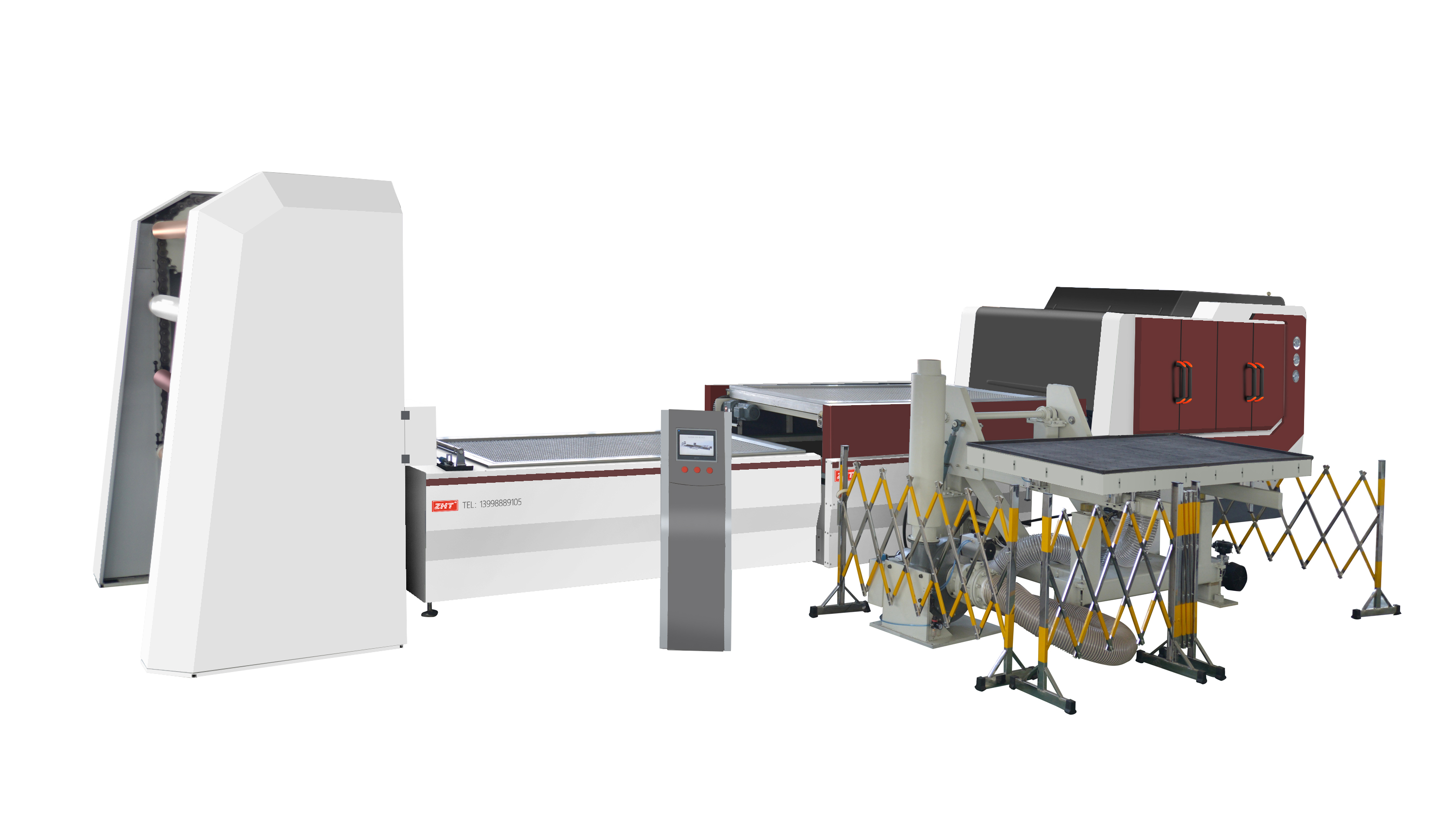

The TM-3000P with automatic pin pedestal system is the pinnacle of Shenyang Zhanhongtu Machinery Equipment Co.,Ltd’s range of air membrane presses. It is designed and engineered for the highest requirements in productivity, flexibility, and reliability. Its creation is the evolution of designing and manufacturing thousands of membrane presses .

Main features of TM-3000P are:

Fast speed:

The working period of ordinary workpiece is less than 2 minutes after it enters the main machine, which is 2-4 times of the efficiency of common positive and negative pressure membrane pressure equipment.

Good effect:

The product processed by common film has clear groove, no open side, bubbling, no color difference, and high light working surface has strong adhesion, and the effect reaches the international leading level.

Low energy consumption:

The total power of the machine is 43KW, which is one half of that of the peer equipment;The main heating starting power is 18KW, and the average power consumption is 13KW/h.

High configuration:

The key part of the machine adopts original parts from Germany, Japan and Taiwan, which is high configuration and stable performance.

High working efficiency:

The whole machine adopts automatic pin system. Compared with other domestic manufacturers, it saves the technological process of making the pad, saves the cost of process raw materials, saves the scanning sequence of the pad of the equipment, saves the time of laminating process, greatly improves the working efficiency and reduces the labor cost.

User-friendly color touch screen interface.

High degree of automation:

The machine is equipped with automatic fabric selection tilting rack, automatic film cutting device, automatic gasket device, laminating device of pressing machine, pallet lifting device and finished product rollover collection device, etc., with high degree of automation, smooth and close process and one-stop film-covering process production.The height of the top block can be selected 12, 15 and 18 mm, solving the phenomenon that the high-light sample block is not in place.

Working effect all can be seen:

The pins can be activated automatically. The pin activation is performed directly in the loading station in full view of the operator. The pins are activated while the tray is stationary in the lay-up station. The operator has the opportunity to visually see that the pins have been correctly activated. The pins are automatically reset at the end of the cycle. The auto reset can be excluded to maintain the setting of the pins from cycle to cycle for repetitive panel dimensions.

Quality and Service are most important things for us

If you have any problem,please let us know