- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TM2580F

ZHT

TM2580F

TOP AND BOTTOM VACUUM SYSTEM MEMBRANE PRESS MACHINE

Function

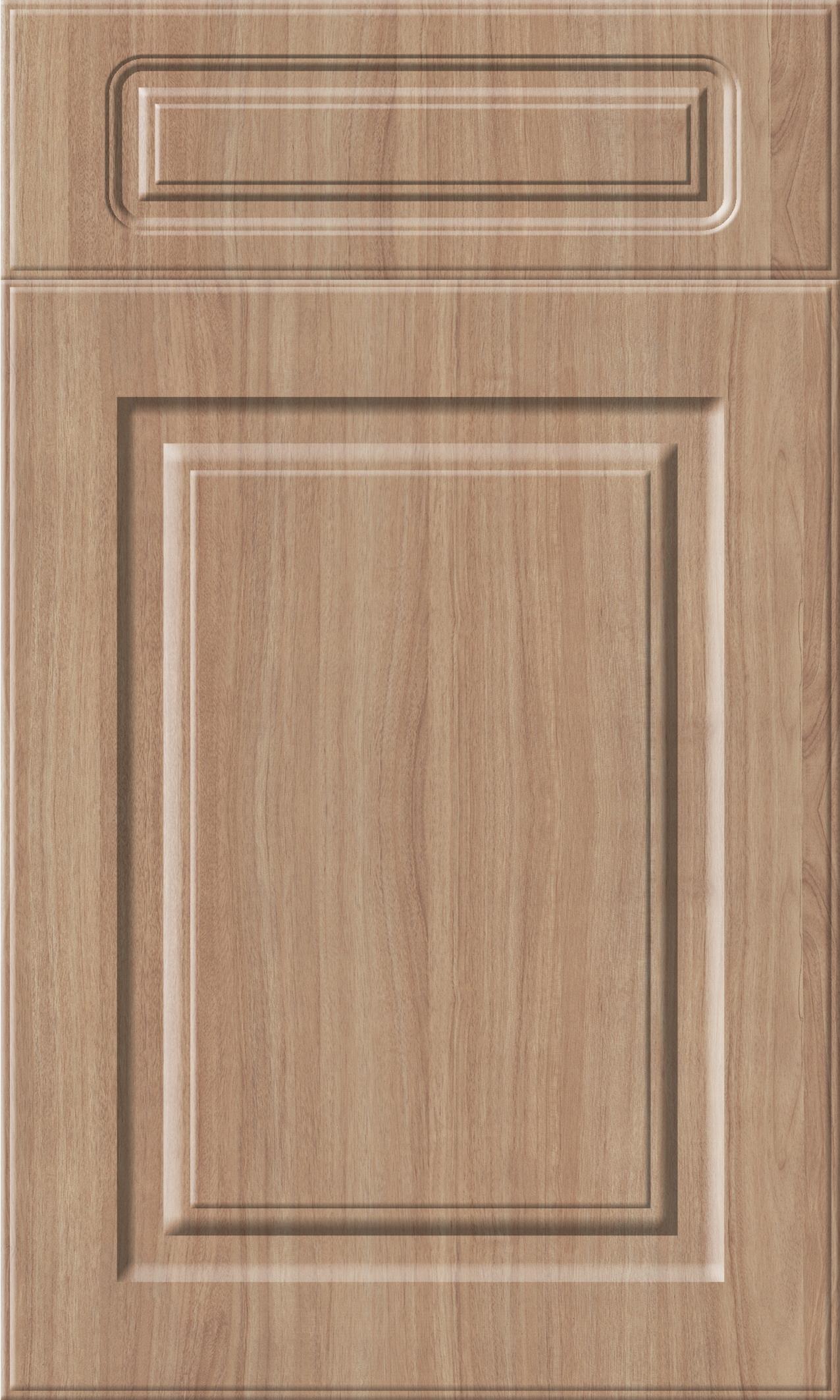

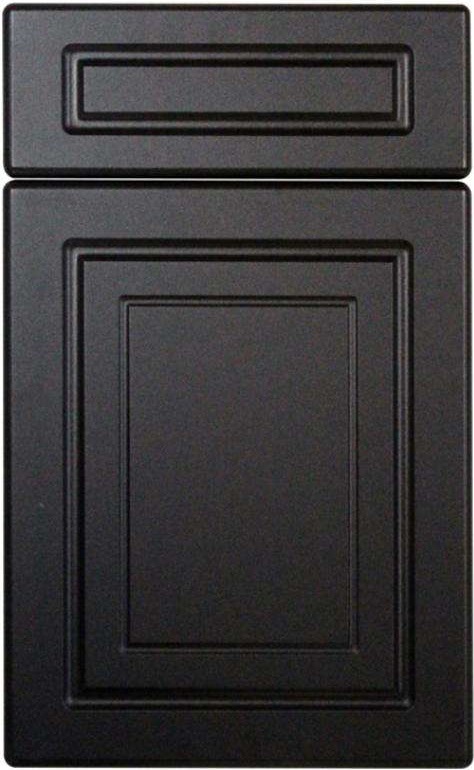

It is used to work on Surface decoration of various high-profile PVC, thermal transfer and single veneer.

Various PVC film can be pasted on furniture, wardrobe, cabinets, acoustics, process doors, Car inner decorating,Advertisement board ,decoration wallboard, etc.,

Features

The key components of the hydraulic system are imported, which are excellent in safety and reliability.

Vacuum pump imported from Germany. Which has powerful engine and stable performance.

The PLC operating system , large screen interface, easy to operate, advanced technology and high degree of automation.

Digital current and voltage display, clear and intuitive. Microcomputer temperature control instrument is used to precisely control the temperature.

Hardware Configuration

Frame | Whole steel plate cut |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder stroke | 200mm |

Hydraulic system | Taiwan |

Heating method | Electrical heating (Nano technology) |

Vacuum pump | SV100 |

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance.

Quality and Service are most important things for us

If you have any problem,please let us know

TOP AND BOTTOM VACUUM SYSTEM MEMBRANE PRESS MACHINE

Function

It is used to work on Surface decoration of various high-profile PVC, thermal transfer and single veneer.

Various PVC film can be pasted on furniture, wardrobe, cabinets, acoustics, process doors, Car inner decorating,Advertisement board ,decoration wallboard, etc.,

Features

The key components of the hydraulic system are imported, which are excellent in safety and reliability.

Vacuum pump imported from Germany. Which has powerful engine and stable performance.

The PLC operating system , large screen interface, easy to operate, advanced technology and high degree of automation.

Digital current and voltage display, clear and intuitive. Microcomputer temperature control instrument is used to precisely control the temperature.

Hardware Configuration

Frame | Whole steel plate cut |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder stroke | 200mm |

Hydraulic system | Taiwan |

Heating method | Electrical heating (Nano technology) |

Vacuum pump | SV100 |

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance.

Quality and Service are most important things for us

If you have any problem,please let us know