- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Dimensions: | |

|---|---|

| Bed dimension: | |

| Total power: | |

| Actual power consumption: | |

| Total weight : | |

| Availability: | |

| Quantity: | |

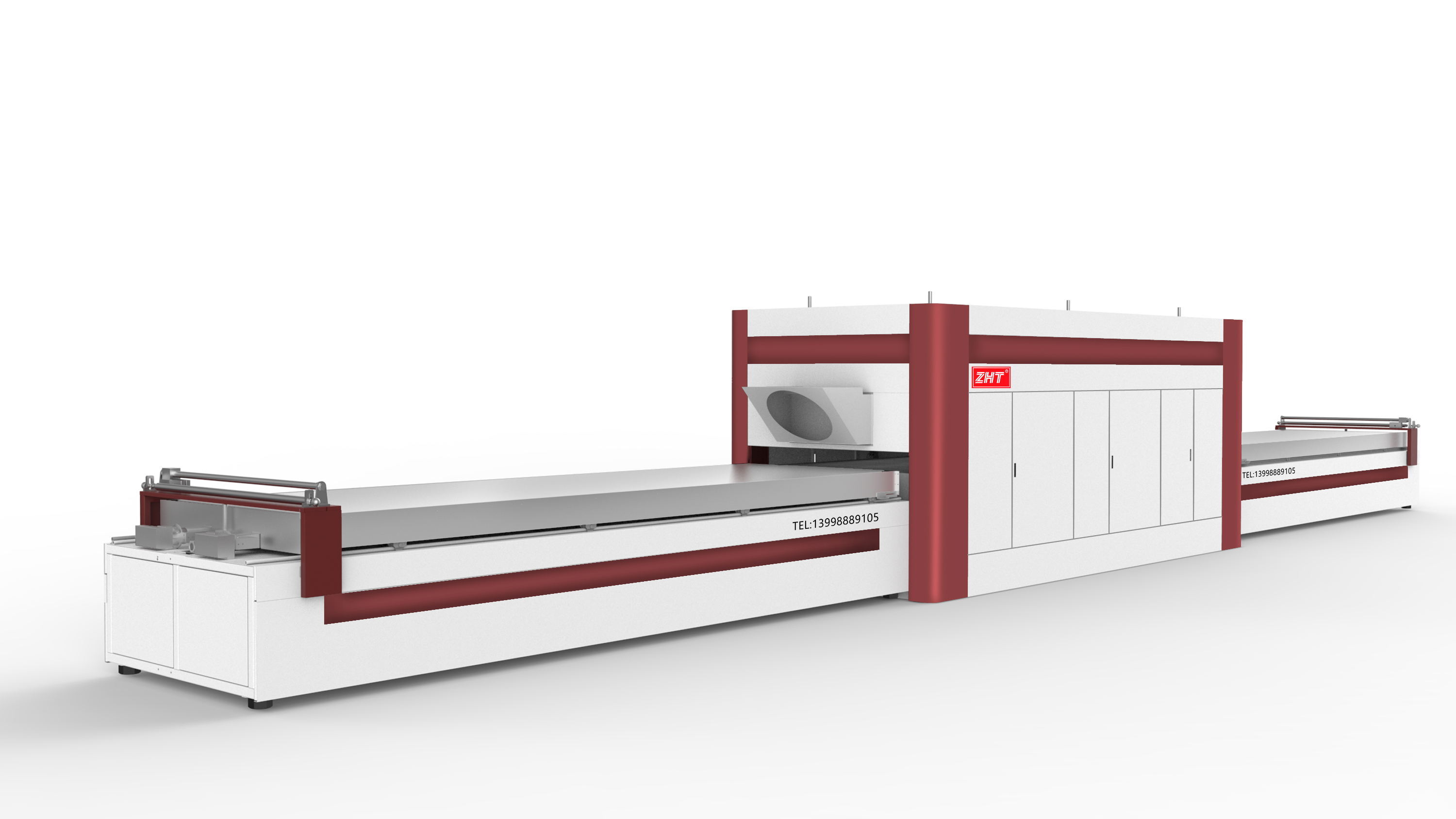

TM4500

ZHT

TM-4500

TM4500 Film Laminating Machine for PVC Paint-free Door

Feature:

1. High automation:

The machine is highly automated, easily operated with automatic feeding. Items of processing time, temperature during the process of manufacture, as well as vacuum degree shall be in the control of digital display instrument.

2. Good heat conductivity:

Aluminum plate shall be used for heating system, which is of high heat conduction for higher rate of finished products.

3. Innovative design:

The machine TM4500 comes out by our technicians out of properties of PVC film to solve the issue of failure to form and to repair one time by ordinary negative press machine.

4. High configuration:

The operation of drive system shall be done by chain drive, double reduction gear applied for feeding to avoid piece malposition, which shall lead to product waste; Electrical devices that imported with stable property shall be used for electrical system, equipped with two operating programs of high automation.

5. High working efficiency:

Heating by special craftsmanship on large bench, which highly improve product efficiency and save cost.

6.High Configuration:

Two antomatic feeding machines for PVC material, films no less than 10 rolls for each.

Technical parameter

Dimensions | 15500mm*2100mm*2000mm |

Bed dimension | 2300mm*1100mm |

Total power | 42.4KW |

Actual power consumption | 13KW |

Total weight | 7T |

Vacuum | ≤-0.095Mpa |

Parts that are easy to damage: gasket, limit switch (not covered by warranty)

Name | Unit | Quantity | Remarks |

Spanner | Bundle | 2 | 17*19,12*14 |

Phillips screwdriver | Bundle | 1 | |

Hexagon spanner 4,6 | Bundle | 2 | |

Hexagon screws | Pcs | 5 | M6*25 |

Fuse | Pcs | 2 | |

Footing | Set | 8 | Double station |

Footing | Set | 8 | Double station |

Galvanized tube | pcs | 1 | Single station |

Galvanized tube | Pcs | 2 | Double station |

PVC bracket | Pcs | 2 | Single station |

PVC bracket | Pcs | 4 | Double station |

Connection cross-bar for PVC bracket | Pcs | 3 | Single station |

Connection cross-bar for PVC bracket | Pcs | 6 | Double station |

Slot type screwdriver | Bundle | 1 | |

Limit Switch | Pcs | 2 |

Properties

1. Select the brand Busch for vacuum pump, Schneider for electrical devices. High efficiency by film laminating on two plates one time on 4.5m (inner diameter) bench with less film.

2. Maintenance: replace oil for vacuum pump every 3-6 months, clean filter every 15 days.

Warranty

1. The supplier will provide free consultation and troubleshooting for repair, maintenance.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the consultancy service,include but not limited to assistances by fhotograph, videos,calls as well as services through social communication softwares like WhatsApp, Skype, etc.

4. The supplier shall send technicians to the demander to install and debug the equipment($200/DAY borne by foreign client for our technicians travelling on business overseas,if necessary) and train the demander's personnel in practical operation, processing and maintenance.

Quality and Service are most important things for us

If you have any problem,please let us know

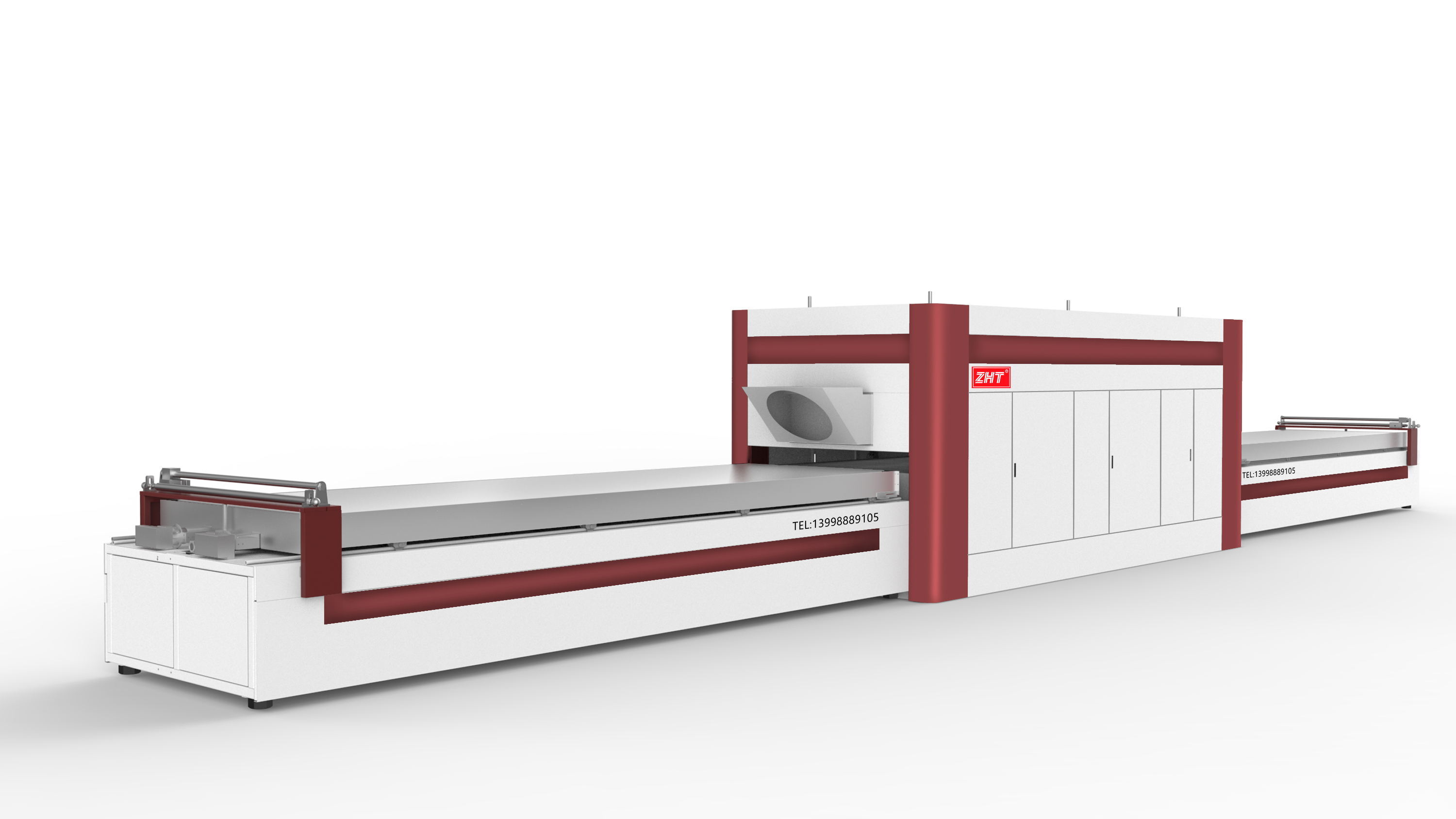

TM4500 Film Laminating Machine for PVC Paint-free Door

Feature:

1. High automation:

The machine is highly automated, easily operated with automatic feeding. Items of processing time, temperature during the process of manufacture, as well as vacuum degree shall be in the control of digital display instrument.

2. Good heat conductivity:

Aluminum plate shall be used for heating system, which is of high heat conduction for higher rate of finished products.

3. Innovative design:

The machine TM4500 comes out by our technicians out of properties of PVC film to solve the issue of failure to form and to repair one time by ordinary negative press machine.

4. High configuration:

The operation of drive system shall be done by chain drive, double reduction gear applied for feeding to avoid piece malposition, which shall lead to product waste; Electrical devices that imported with stable property shall be used for electrical system, equipped with two operating programs of high automation.

5. High working efficiency:

Heating by special craftsmanship on large bench, which highly improve product efficiency and save cost.

6.High Configuration:

Two antomatic feeding machines for PVC material, films no less than 10 rolls for each.

Technical parameter

Dimensions | 15500mm*2100mm*2000mm |

Bed dimension | 2300mm*1100mm |

Total power | 42.4KW |

Actual power consumption | 13KW |

Total weight | 7T |

Vacuum | ≤-0.095Mpa |

Parts that are easy to damage: gasket, limit switch (not covered by warranty)

Name | Unit | Quantity | Remarks |

Spanner | Bundle | 2 | 17*19,12*14 |

Phillips screwdriver | Bundle | 1 | |

Hexagon spanner 4,6 | Bundle | 2 | |

Hexagon screws | Pcs | 5 | M6*25 |

Fuse | Pcs | 2 | |

Footing | Set | 8 | Double station |

Footing | Set | 8 | Double station |

Galvanized tube | pcs | 1 | Single station |

Galvanized tube | Pcs | 2 | Double station |

PVC bracket | Pcs | 2 | Single station |

PVC bracket | Pcs | 4 | Double station |

Connection cross-bar for PVC bracket | Pcs | 3 | Single station |

Connection cross-bar for PVC bracket | Pcs | 6 | Double station |

Slot type screwdriver | Bundle | 1 | |

Limit Switch | Pcs | 2 |

Properties

1. Select the brand Busch for vacuum pump, Schneider for electrical devices. High efficiency by film laminating on two plates one time on 4.5m (inner diameter) bench with less film.

2. Maintenance: replace oil for vacuum pump every 3-6 months, clean filter every 15 days.

Warranty

1. The supplier will provide free consultation and troubleshooting for repair, maintenance.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the consultancy service,include but not limited to assistances by fhotograph, videos,calls as well as services through social communication softwares like WhatsApp, Skype, etc.

4. The supplier shall send technicians to the demander to install and debug the equipment($200/DAY borne by foreign client for our technicians travelling on business overseas,if necessary) and train the demander's personnel in practical operation, processing and maintenance.

Quality and Service are most important things for us

If you have any problem,please let us know