- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

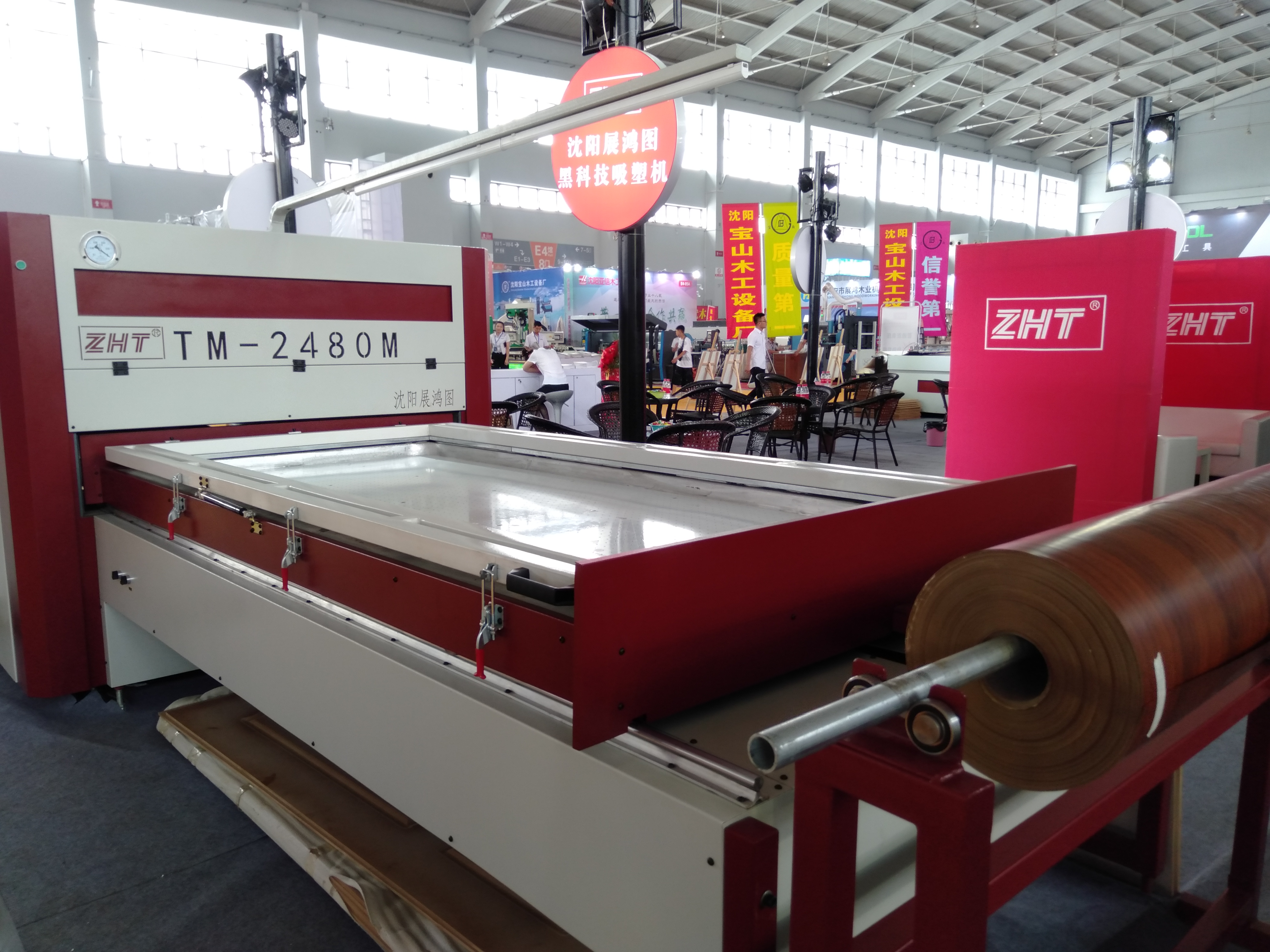

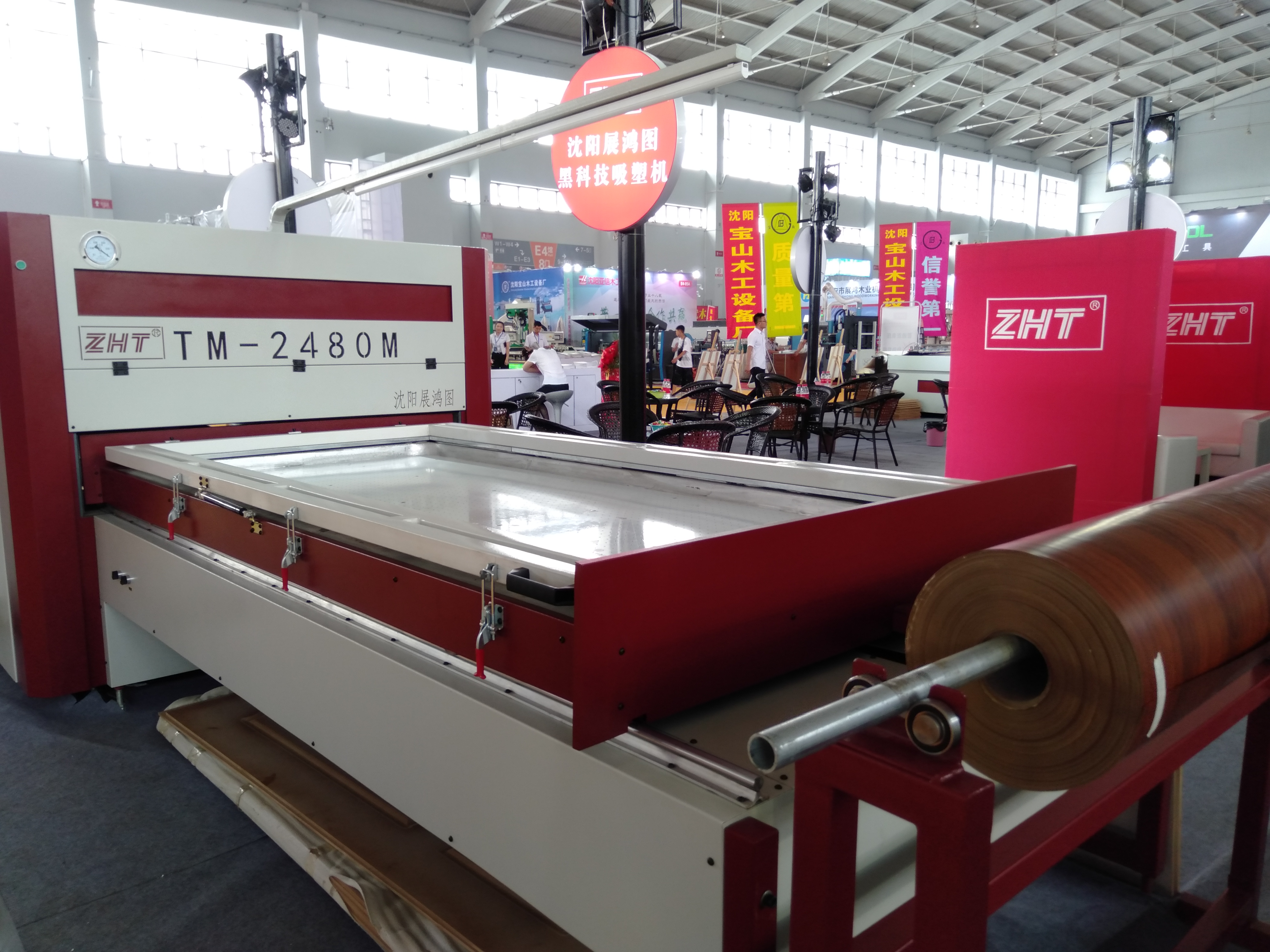

TM-2480M

ZHT

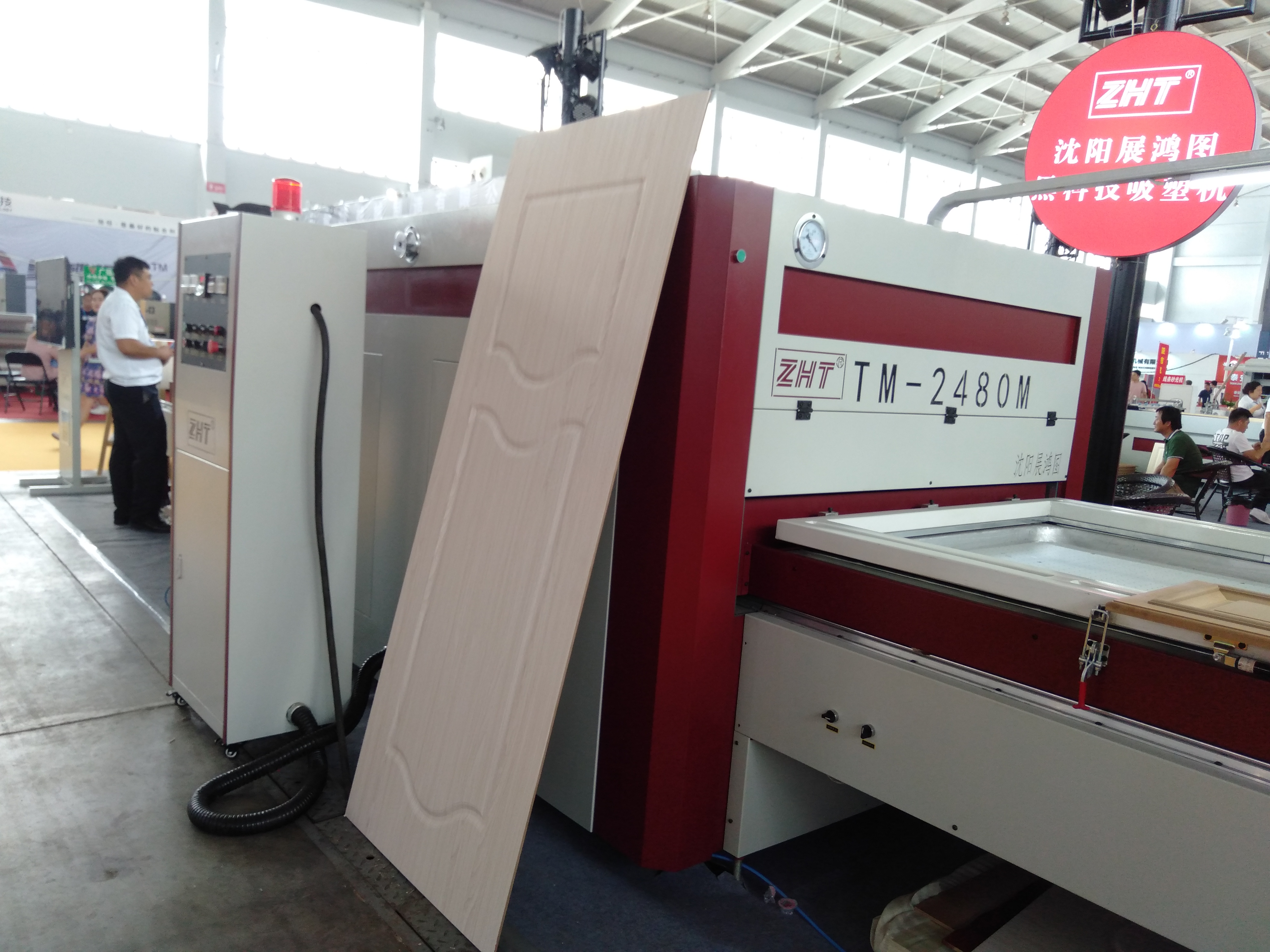

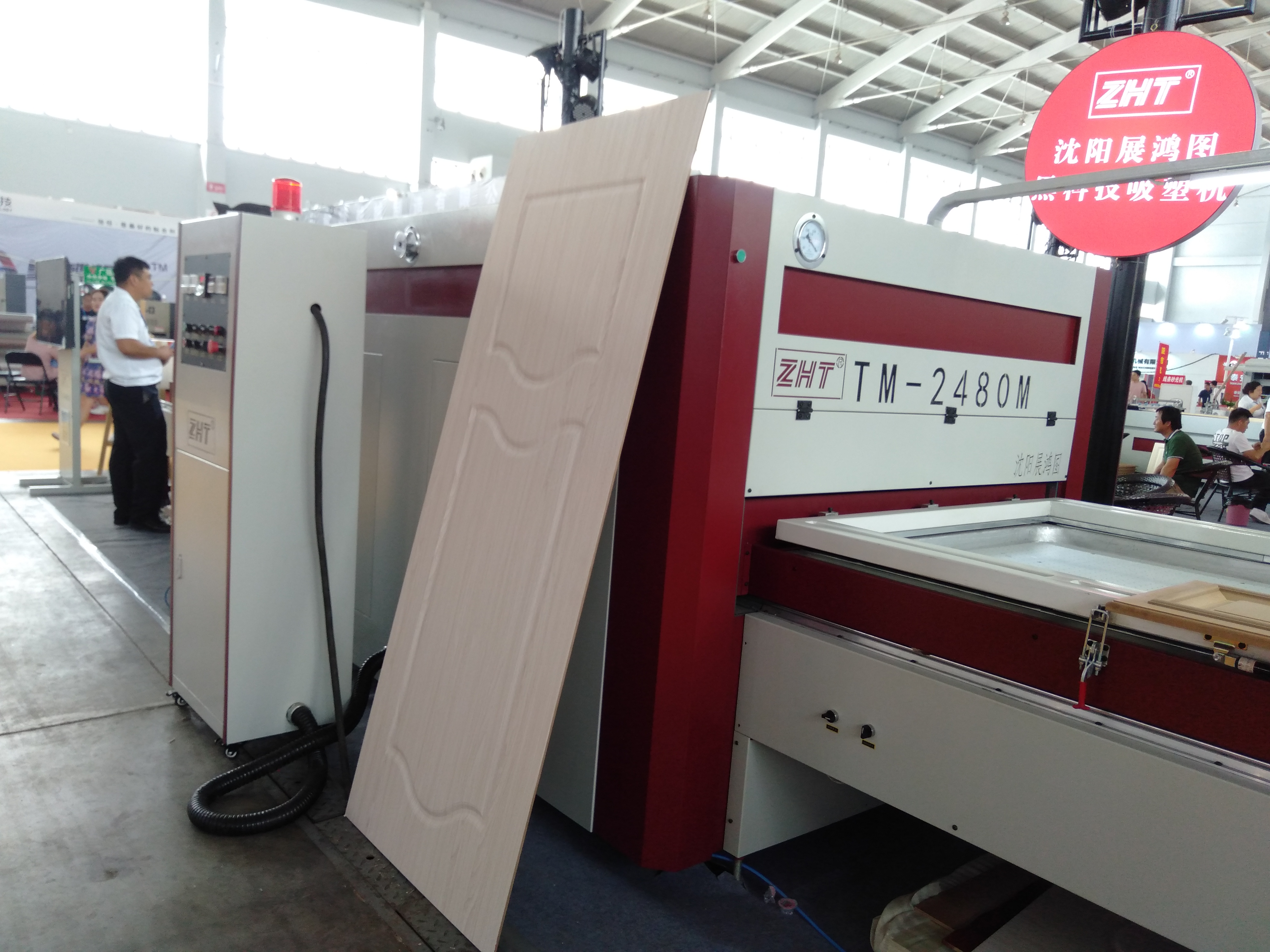

TM2480M pvc foil vacuum membrane press machine for PVC Paint-Free Door

Function

This machine specially designed for paint free doors, it uses air pressure to press PVC film on MDF wooden panels. With the advantages of: Bright in colorful;strong corrosion resistance;good heat resistance;sun-proof ;flame retarded;eco-friendly it rapidly received a large arrange of high praise.

This machine is a fully automatic vacuum coating equipment, which can be used for surface finishing of various kinds of high-grade PVC.

The machine is highly automatic and easy to operate. The work table is fully automatic in and out of the warehouse.The processing time, processing temperature and vacuum in the warehouse are automatically controlled by digital display, thus ensuring product quality and improving production efficiency.

Features

1、Membrane is fed steadily without creases curled edges or wrinkle.

2、Benefits from rationality of structure design,membrane receives less tensile force so it barely had no color variation.

3、Do not need compressing-frame to hold the membrane in some way it saves PVC membrane.

4、The whole working process from work-piece incoming to finish processing takes less than one minute.

5、Adopts high quality Imported vacuum pump which performs more stable.

6、Special technology to prevent film wrinkles

Available configurations are:

1、single tray for door skin

2、single tray for glazed door

3、twin tray with both side for door skin

4、twin tray with both side for glazed door

5、twin tray with one side for door skin,one side for glazed door

Note: We can upgrade workbench with auto PIN SYSTEM for any used positive and negative pressure membrane press machine

If you need we can help design.

Technical parameter

Dimensions | 9950mm x1900mm x1770mm |

Bed dimension(for glazed glass door) | 2550mm x1100mm |

Bed dimension(for door panel) | 2500mm x 1280mm |

weight | 2.5T |

Total power | 15kw |

Actual power consumption | 5kw |

Voltage | 380V 50HZ optional |

Rated working pressure | negative pressure ≥-0.095Mpa |

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance

Quality and Service are most important things for us

If you have any problem,please let us know

TM2480M pvc foil vacuum membrane press machine for PVC Paint-Free Door

Function

This machine specially designed for paint free doors, it uses air pressure to press PVC film on MDF wooden panels. With the advantages of: Bright in colorful;strong corrosion resistance;good heat resistance;sun-proof ;flame retarded;eco-friendly it rapidly received a large arrange of high praise.

This machine is a fully automatic vacuum coating equipment, which can be used for surface finishing of various kinds of high-grade PVC.

The machine is highly automatic and easy to operate. The work table is fully automatic in and out of the warehouse.The processing time, processing temperature and vacuum in the warehouse are automatically controlled by digital display, thus ensuring product quality and improving production efficiency.

Features

1、Membrane is fed steadily without creases curled edges or wrinkle.

2、Benefits from rationality of structure design,membrane receives less tensile force so it barely had no color variation.

3、Do not need compressing-frame to hold the membrane in some way it saves PVC membrane.

4、The whole working process from work-piece incoming to finish processing takes less than one minute.

5、Adopts high quality Imported vacuum pump which performs more stable.

6、Special technology to prevent film wrinkles

Available configurations are:

1、single tray for door skin

2、single tray for glazed door

3、twin tray with both side for door skin

4、twin tray with both side for glazed door

5、twin tray with one side for door skin,one side for glazed door

Note: We can upgrade workbench with auto PIN SYSTEM for any used positive and negative pressure membrane press machine

If you need we can help design.

Technical parameter

Dimensions | 9950mm x1900mm x1770mm |

Bed dimension(for glazed glass door) | 2550mm x1100mm |

Bed dimension(for door panel) | 2500mm x 1280mm |

weight | 2.5T |

Total power | 15kw |

Actual power consumption | 5kw |

Voltage | 380V 50HZ optional |

Rated working pressure | negative pressure ≥-0.095Mpa |

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall provide technical support to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance

Quality and Service are most important things for us

If you have any problem,please let us know