- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TM2580F

Furniture Vacuum Membrane Press Machine TM2580F

Features

1. Fast speed: the working period of ordinary workpiece is less than 2 minutes after it enters the main machine, which is 2-4 times of the efficiency of common positive and negative pressure membrane pressure equipment.

2. Good effect: the product processed by common film has clear groove, no open side, bubbling, no color difference, and high light working surface has strong adhesion, and the effect reaches the international leading level.

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Upgrade improvements

1. The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

2. The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

3. The lifting balance system is easy to adjust, and the rise and fall are more stable.

4. Hydraulic system oil port improvement and maintenance is more convenient.

5. The aluminum frame is processed by one body, and no weld seam increases the strength.

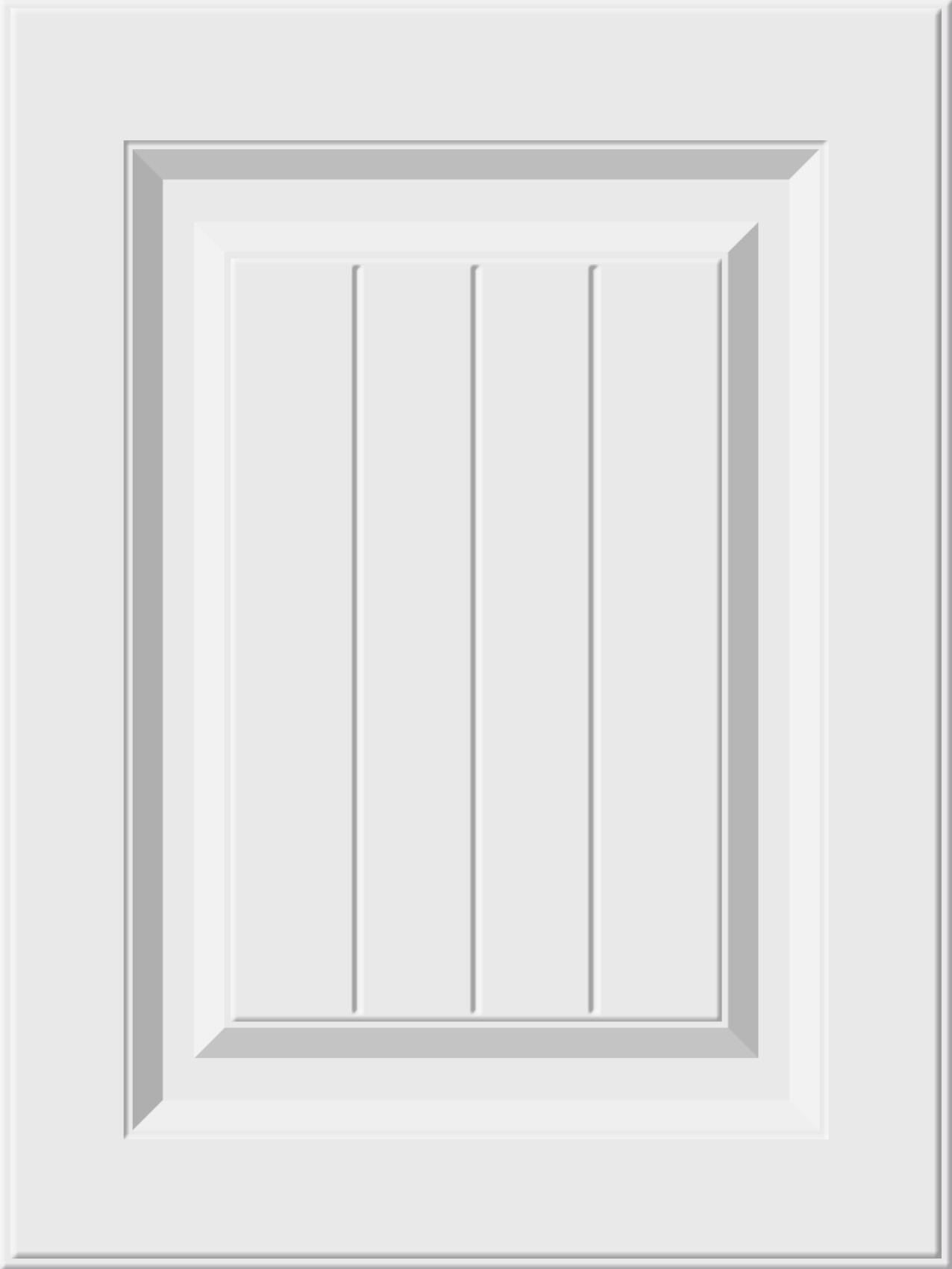

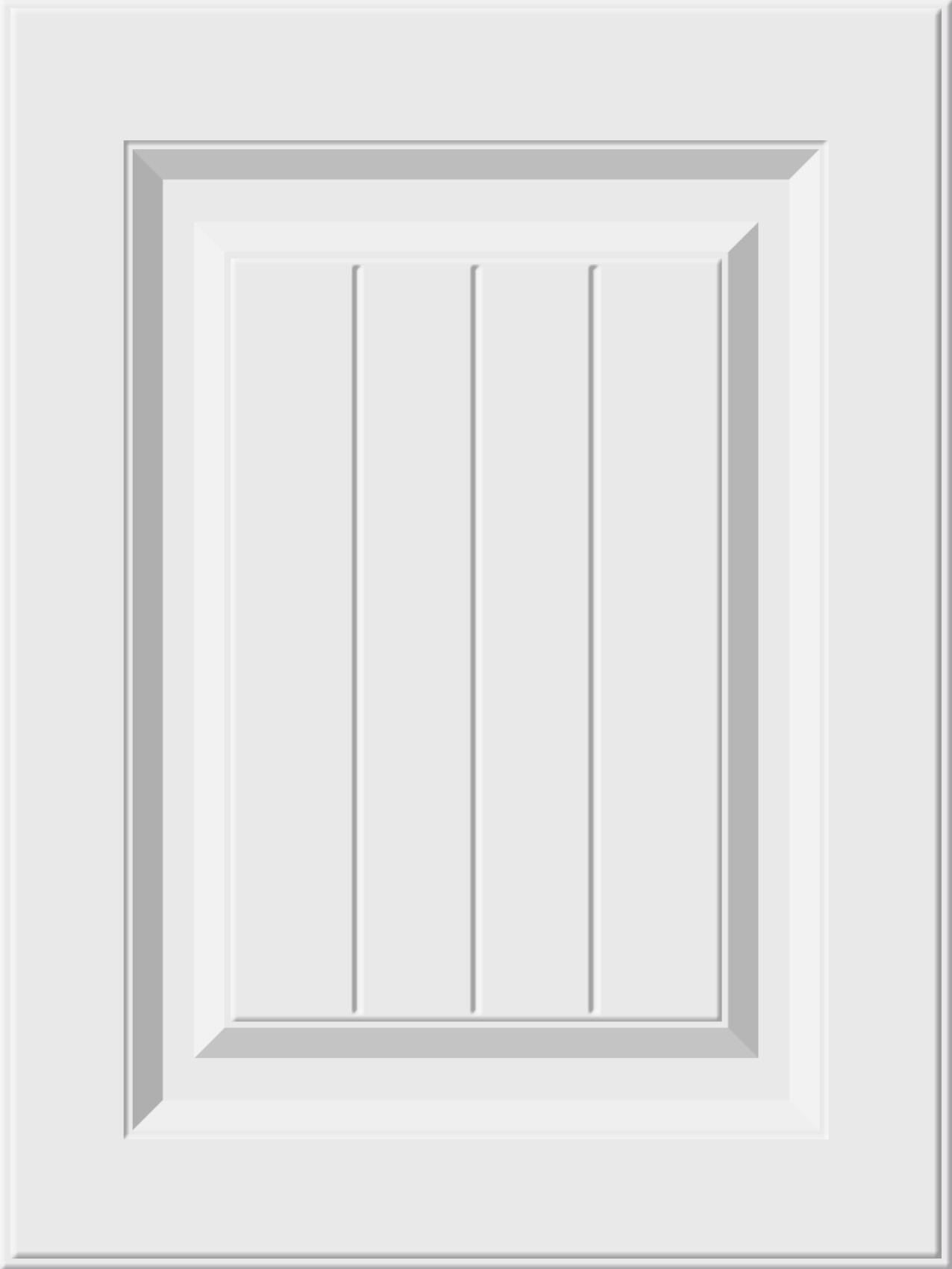

workpiece display

Component display

Solid 180mm cylinder Rack blasting Lifting system

Upper tray PVC bracket Aluminum frame

Furniture Vacuum Membrane Press Machine TM2580F

Features

1. Fast speed: the working period of ordinary workpiece is less than 2 minutes after it enters the main machine, which is 2-4 times of the efficiency of common positive and negative pressure membrane pressure equipment.

2. Good effect: the product processed by common film has clear groove, no open side, bubbling, no color difference, and high light working surface has strong adhesion, and the effect reaches the international leading level.

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Upgrade improvements

1. The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

2. The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

3. The lifting balance system is easy to adjust, and the rise and fall are more stable.

4. Hydraulic system oil port improvement and maintenance is more convenient.

5. The aluminum frame is processed by one body, and no weld seam increases the strength.

workpiece display

Component display

Solid 180mm cylinder Rack blasting Lifting system

Upper tray PVC bracket Aluminum frame