- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TM2480M

ZHT

Anti-corrugation model TM2480M

1、 Model TM2480M

2、 Dimension 10300MM×1920MM×1730MM

3、 Worktable size 2550(2350)MM×1150MM×40MM

4、 Maximum working surface

2550(2350) MM×1150MM×40MM

5、 Maximum height of workpiece 60MM

6、 Total power 15KW

7、 Actual power consumption 5KW

8、 Total weight 2000(2500)KG

9、 Vacuum level ≥ -0.095Mpa to -0.08Mpa

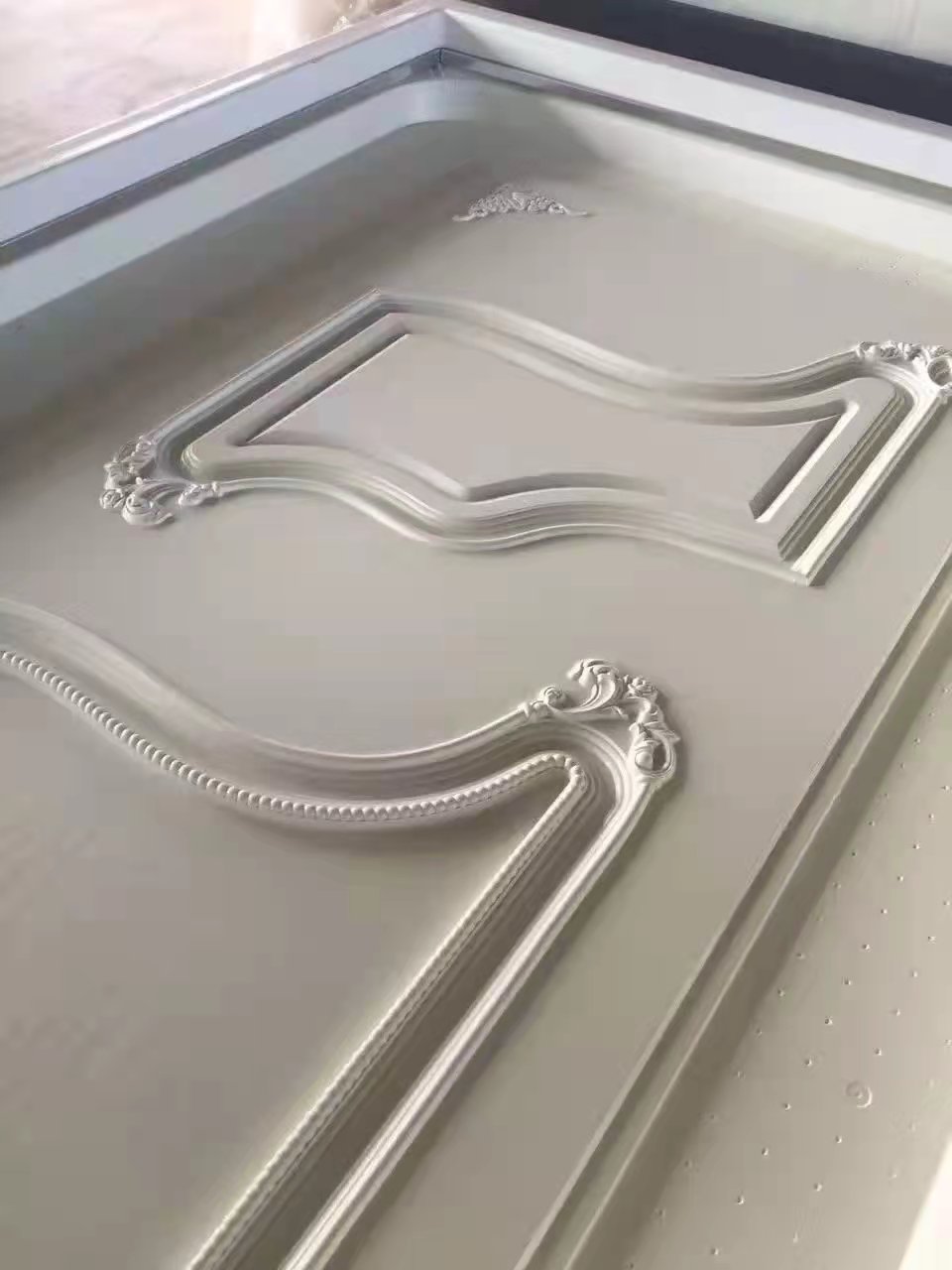

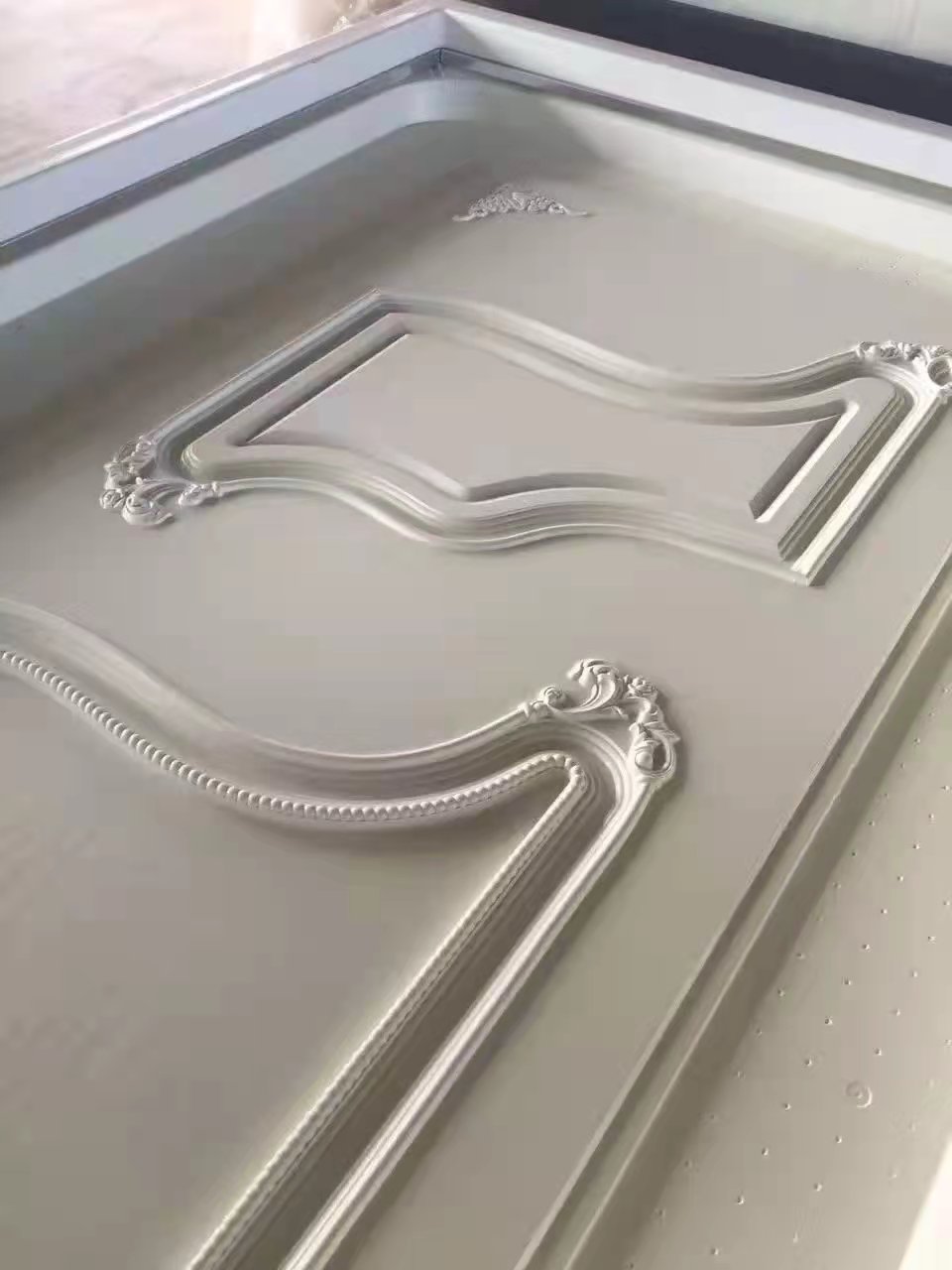

TM series vacuum laminating machine is an economical and practical vacuum laminating equipment designed and manufactured by our company on the basis of absorbing advanced technology and experience from abroad. The machine can laminate various kinds of PVC masks on various shapes of substrates, such as imitation wood, stone, leather, etc.

After years of production practice and experience, our TM type laminating machine adopts German vacuum technology and chooses domestic 2X series vacuum pump with excellent performance and electric motor as the core of power. The machine is compact and easy to operate, the heating bin is light and easy to move, and there are two kinds of working tables of different sizes to use different widths of masks. The processing time of the workpiece, processing temperature and vacuum degree in the bin are automatically controlled by digital display, thus ensuring the quality of the product and improving the production efficiency and the finished product rate.

According to the needs, our company has manual, semi-automatic, automatic and single table, double table, full width, full narrow and one wide and one narrow table series products for customers to choose.

In recent years, our products have started to be exported to Southeast Asia, Russia, Canada and other countries and regions under the human approval of customers.

Note: Optional German vacuum pump is available.

1, molding processing parts to pay attention to the surface of the workpiece to be laminated to sand, remove the surface of the wood chips and residues.

2、In order to achieve good lamination effect, rounded or beveled corners are recommended for the edges of the workpiece and the bottom of the molding.

3, the workpiece lamination part of the glue spraying to be uniform, not leak empty.

4、The glue sprayed workpiece must be dried before entering the laminating process for processing.

5、The workpiece should be placed on the workbench to maintain the corresponding distance (generally more than 2 times the height of the workpiece) to avoid the rupture of the PVC film caused by suction coating, resulting in scrap.

6、Avoid sharp workpieces from damaging the PVC film during the operation.

7、The workpiece should be padded with a pad, and the pad thickness and the thickness of the workpiece should be approximately the same, the pad surface should be slightly smaller than the workpiece 5MM, the pad should be flat, otherwise the workpiece will be fractured and cause scrap due to the large suction force during the suction, the pad should have good air permeability.

8, due to the PVC film leakage caused by the processing of individual parts of the film is not good, available transparent tape to seal the hole, and then sent to the work of the warehouse temperature absorption, individual places such as the glue is not dry caused by the absorption of bad, available electric hair dryer to heat repair.

9、After the workpiece is processed, the excess PVC film is cut off with a paper cutter.

Equipment maintenance requirements

1. Keep the inside of the workbench clean to prevent dust from entering the vacuum machine.

2. Keep the vacuum pipeline unblocked.

3. Frequently check the oil volume of the vacuum pump, replenish it in time, replace the vacuum oil regularly, and do not replace it with other oils

4. The pressing handle of the workbench should be refueled regularly to keep it lubricated.

5. In order to ensure the safety and normal operation of the machine, do not make the machine work beyond the design indicators of the machine.

6. When using maintenance parts not provided by our factory, you should consult our factory to avoid danger.

Note: Special oil for vacuum pumps, such as vacuum No. 1 oil for belt pumps, and N68# oil for direct-coupled pumps

Anti-corrugation model TM2480M

1、 Model TM2480M

2、 Dimension 10300MM×1920MM×1730MM

3、 Worktable size 2550(2350)MM×1150MM×40MM

4、 Maximum working surface

2550(2350) MM×1150MM×40MM

5、 Maximum height of workpiece 60MM

6、 Total power 15KW

7、 Actual power consumption 5KW

8、 Total weight 2000(2500)KG

9、 Vacuum level ≥ -0.095Mpa to -0.08Mpa

TM series vacuum laminating machine is an economical and practical vacuum laminating equipment designed and manufactured by our company on the basis of absorbing advanced technology and experience from abroad. The machine can laminate various kinds of PVC masks on various shapes of substrates, such as imitation wood, stone, leather, etc.

After years of production practice and experience, our TM type laminating machine adopts German vacuum technology and chooses domestic 2X series vacuum pump with excellent performance and electric motor as the core of power. The machine is compact and easy to operate, the heating bin is light and easy to move, and there are two kinds of working tables of different sizes to use different widths of masks. The processing time of the workpiece, processing temperature and vacuum degree in the bin are automatically controlled by digital display, thus ensuring the quality of the product and improving the production efficiency and the finished product rate.

According to the needs, our company has manual, semi-automatic, automatic and single table, double table, full width, full narrow and one wide and one narrow table series products for customers to choose.

In recent years, our products have started to be exported to Southeast Asia, Russia, Canada and other countries and regions under the human approval of customers.

Note: Optional German vacuum pump is available.

1, molding processing parts to pay attention to the surface of the workpiece to be laminated to sand, remove the surface of the wood chips and residues.

2、In order to achieve good lamination effect, rounded or beveled corners are recommended for the edges of the workpiece and the bottom of the molding.

3, the workpiece lamination part of the glue spraying to be uniform, not leak empty.

4、The glue sprayed workpiece must be dried before entering the laminating process for processing.

5、The workpiece should be placed on the workbench to maintain the corresponding distance (generally more than 2 times the height of the workpiece) to avoid the rupture of the PVC film caused by suction coating, resulting in scrap.

6、Avoid sharp workpieces from damaging the PVC film during the operation.

7、The workpiece should be padded with a pad, and the pad thickness and the thickness of the workpiece should be approximately the same, the pad surface should be slightly smaller than the workpiece 5MM, the pad should be flat, otherwise the workpiece will be fractured and cause scrap due to the large suction force during the suction, the pad should have good air permeability.

8, due to the PVC film leakage caused by the processing of individual parts of the film is not good, available transparent tape to seal the hole, and then sent to the work of the warehouse temperature absorption, individual places such as the glue is not dry caused by the absorption of bad, available electric hair dryer to heat repair.

9、After the workpiece is processed, the excess PVC film is cut off with a paper cutter.

Equipment maintenance requirements

1. Keep the inside of the workbench clean to prevent dust from entering the vacuum machine.

2. Keep the vacuum pipeline unblocked.

3. Frequently check the oil volume of the vacuum pump, replenish it in time, replace the vacuum oil regularly, and do not replace it with other oils

4. The pressing handle of the workbench should be refueled regularly to keep it lubricated.

5. In order to ensure the safety and normal operation of the machine, do not make the machine work beyond the design indicators of the machine.

6. When using maintenance parts not provided by our factory, you should consult our factory to avoid danger.

Note: Special oil for vacuum pumps, such as vacuum No. 1 oil for belt pumps, and N68# oil for direct-coupled pumps