- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

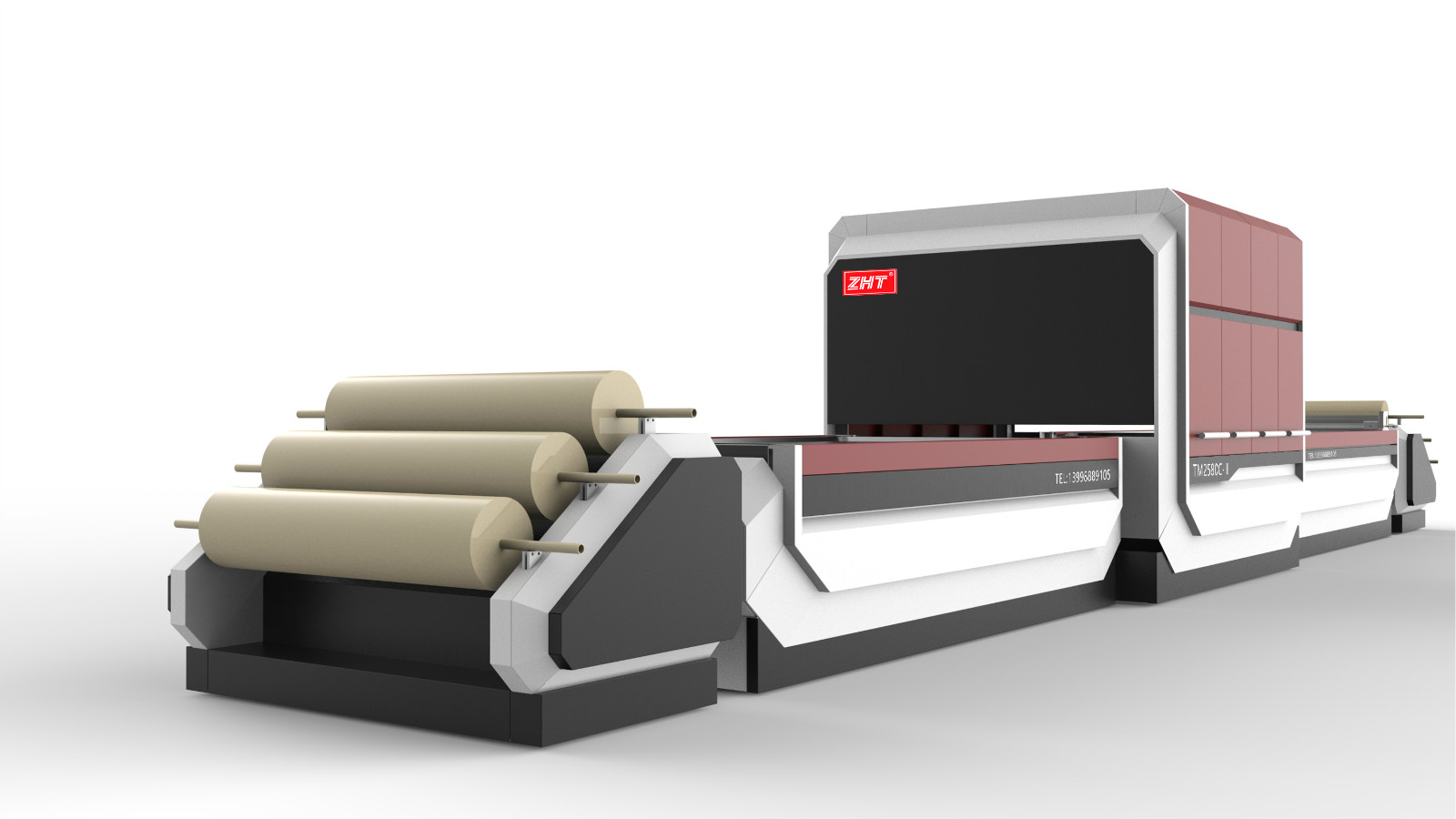

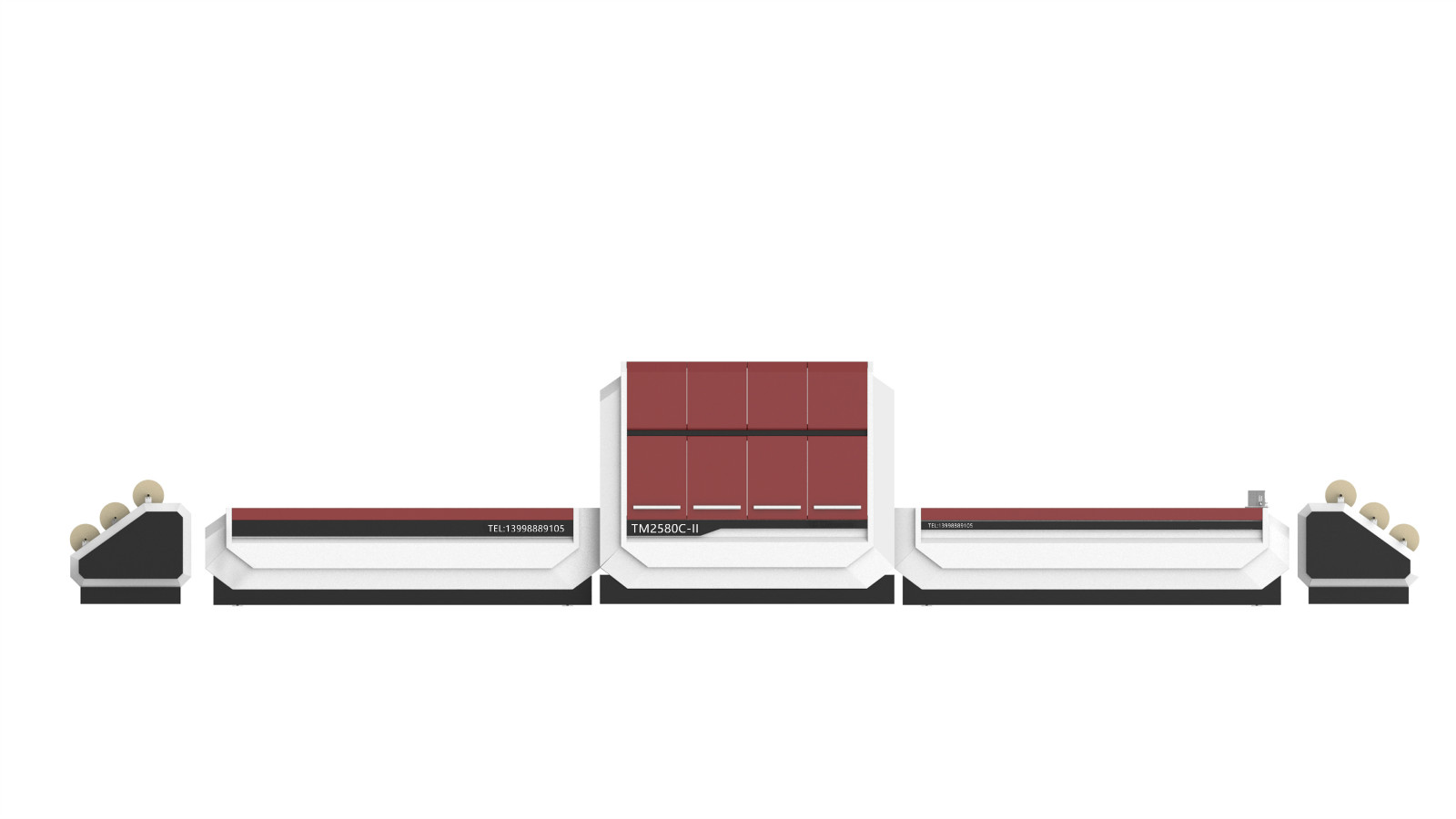

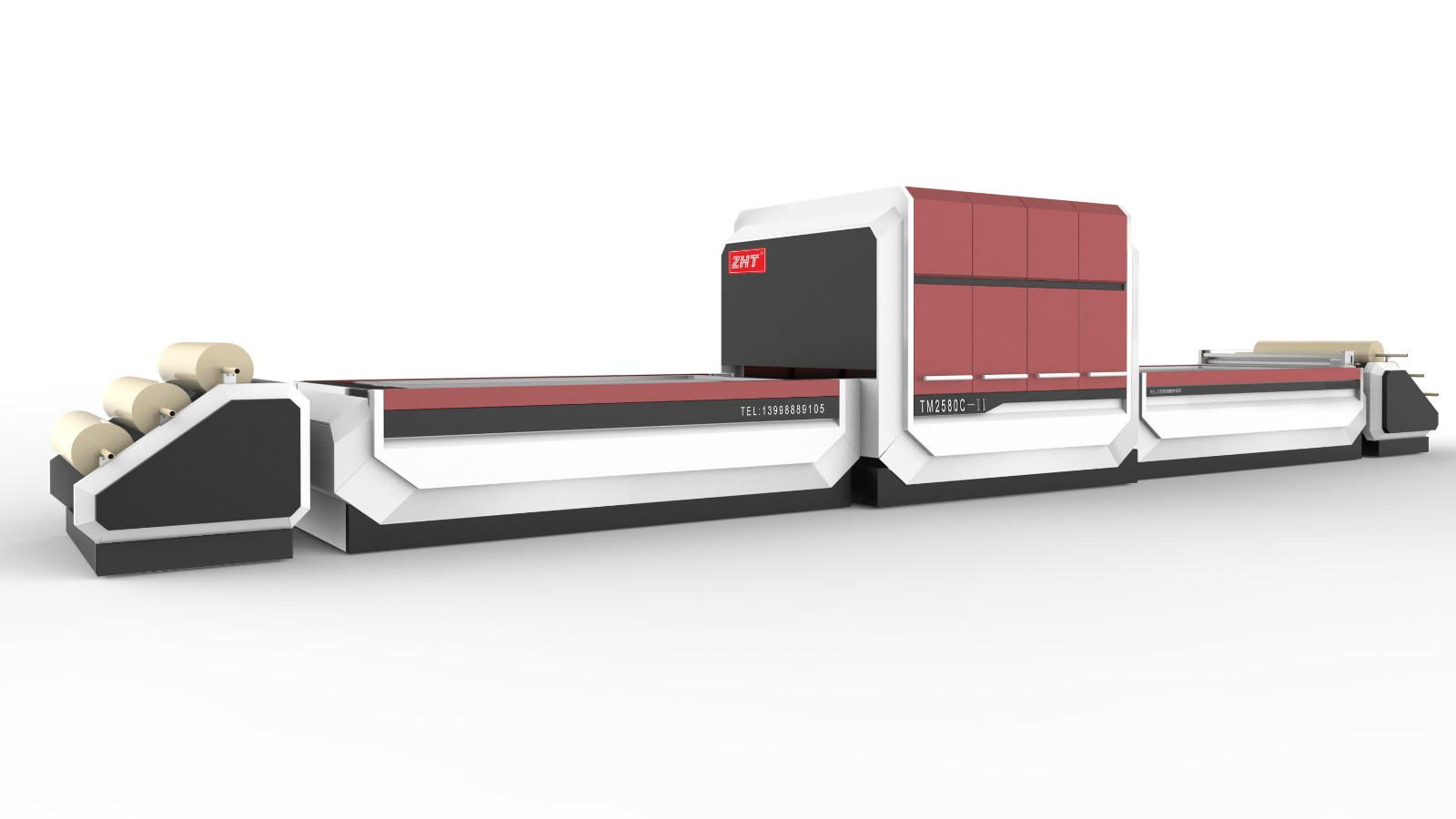

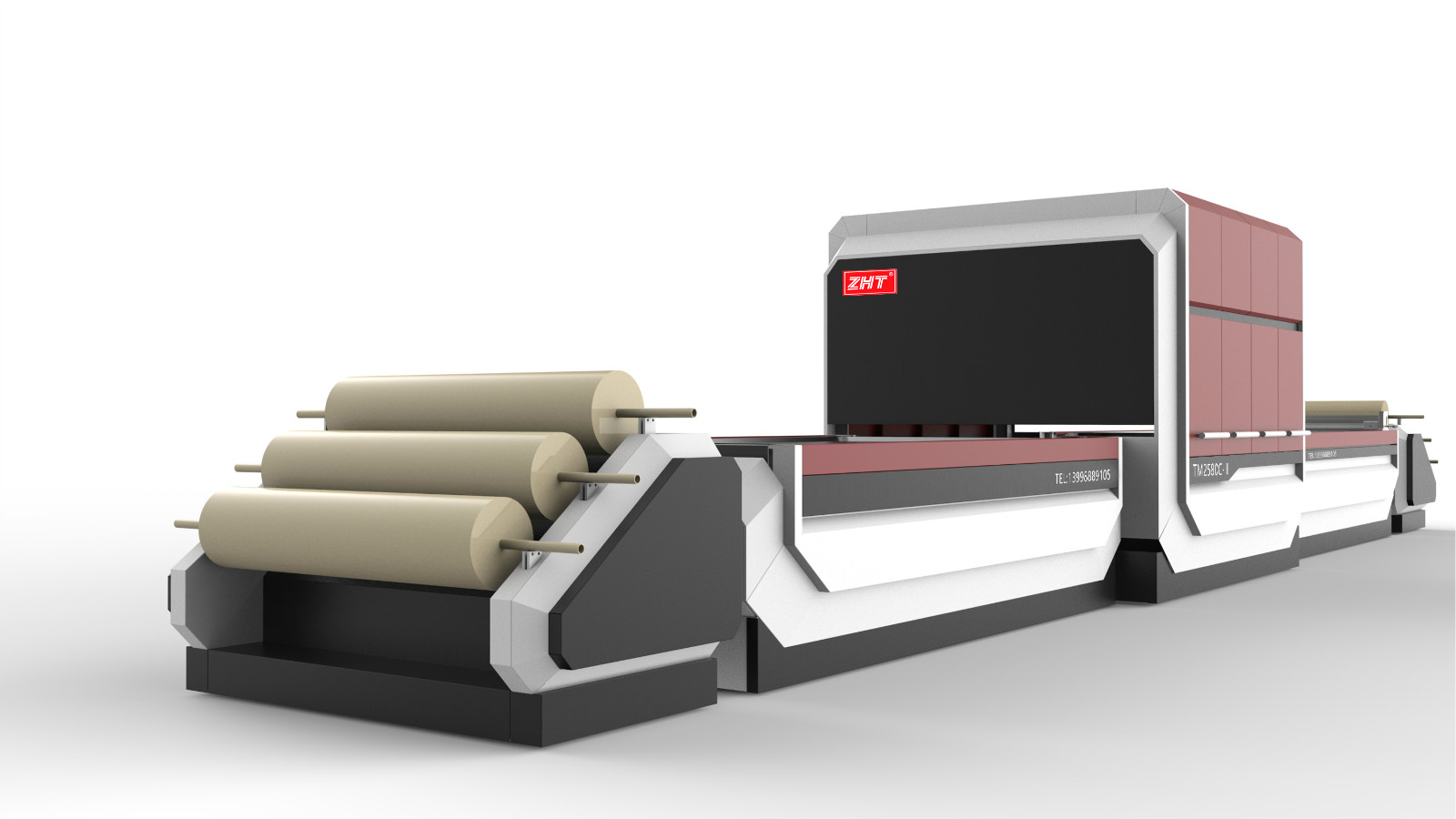

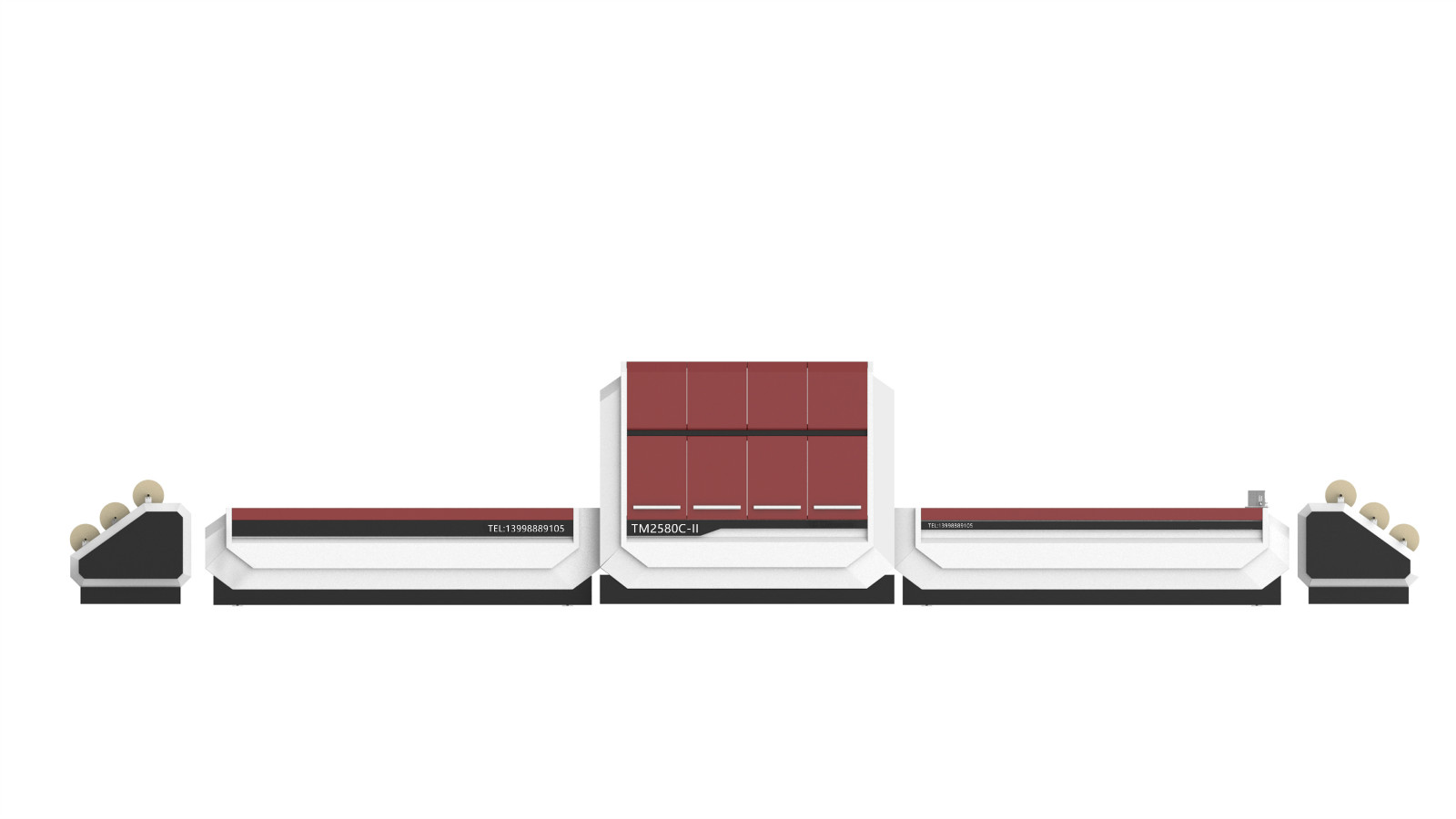

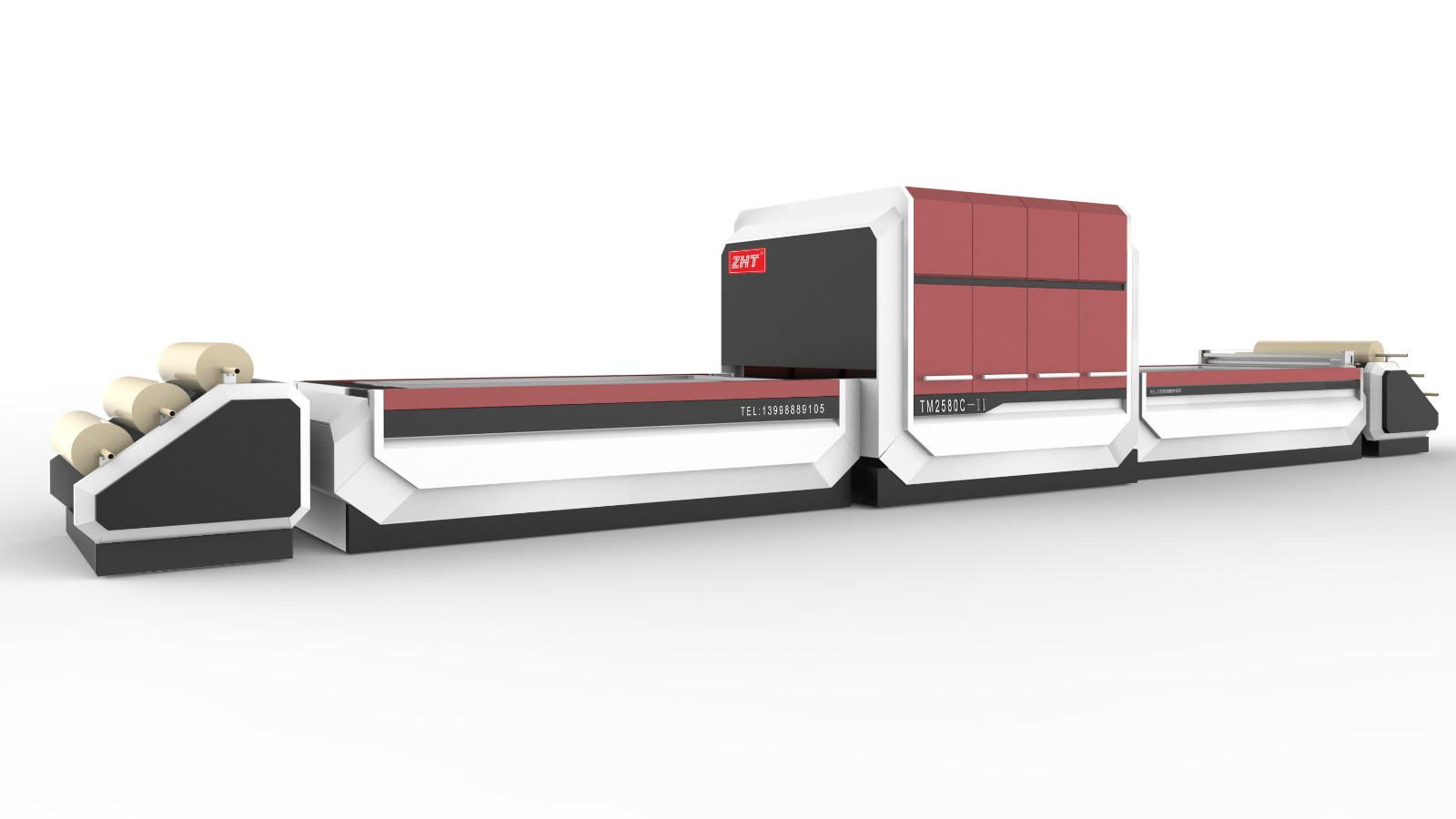

TM-2580C-Ⅱ

ZHT

Professional Mdf Cabinet Door Vacuum Membrane Press Machine

Introduction

It is used to work various high-profile PVC, hot transfer and single veneer

All kinds of PVC workpieces processed by this machine stick firmly, do not bounce off the edge.Line of groove is clear and in place.

Features

The key parts of hydraulic system adopt the import parts, the safe and reliable technology is excellent.

Vacuum pump imported from Germany, high horsepower, low fault rate.

The operating system adopts PLC to control large screen HMI, which is convenient to control, advanced in technology and high in automation.

Digital display current, voltage display, clear and intuitive.Microcomputer temperature control instrument is used for accurate temperature control.

Technical parameter

| Dimensions | 9930mm*2230mm*2150mm |

| Bed dimension | 2550mm*1270mm(inner diameter) |

| Maximum machining height | 50mm |

| Rated working pressure | positive pressure ≤0.6Mpa negative pressure ≥-0.095Mpa |

| Total power | 49.5KW |

| Actual power consumption | About 16KW |

| Total weight | 14T |

How it works

Preheating equipment

Put cabinet door on the workbench

Put cabinet door on the workbench

Pull the PVC membrane and cover cabinet door

Cutting membrane

Enter the host machine

The membrane floating up and heating

Vacuum plus negative pressure plus positive pressure

Release of positive and negative pressure

Unloading hydraulic

Drop workbench

Workbench out

Work end

Sample

Quality and Service are most important things for us

If you have any problem,please let us know

Professional Mdf Cabinet Door Vacuum Membrane Press Machine

Introduction

It is used to work various high-profile PVC, hot transfer and single veneer

All kinds of PVC workpieces processed by this machine stick firmly, do not bounce off the edge.Line of groove is clear and in place.

Features

The key parts of hydraulic system adopt the import parts, the safe and reliable technology is excellent.

Vacuum pump imported from Germany, high horsepower, low fault rate.

The operating system adopts PLC to control large screen HMI, which is convenient to control, advanced in technology and high in automation.

Digital display current, voltage display, clear and intuitive.Microcomputer temperature control instrument is used for accurate temperature control.

Technical parameter

| Dimensions | 9930mm*2230mm*2150mm |

| Bed dimension | 2550mm*1270mm(inner diameter) |

| Maximum machining height | 50mm |

| Rated working pressure | positive pressure ≤0.6Mpa negative pressure ≥-0.095Mpa |

| Total power | 49.5KW |

| Actual power consumption | About 16KW |

| Total weight | 14T |

How it works

Preheating equipment

Put cabinet door on the workbench

Put cabinet door on the workbench

Pull the PVC membrane and cover cabinet door

Cutting membrane

Enter the host machine

The membrane floating up and heating

Vacuum plus negative pressure plus positive pressure

Release of positive and negative pressure

Unloading hydraulic

Drop workbench

Workbench out

Work end

Sample

Quality and Service are most important things for us

If you have any problem,please let us know