- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

TM2580F

ZHT

Vacuum Upper Pressure Membrane Machine Specification

Features

1. Fast speed: the working period of ordinary workpiece is less than 2 minutes after it enters the main machine, which is 2-4 times of the efficiency of common positive and negative pressure membrane pressure equipment.

2. Good effect: the product processed by common film has clear groove, no open side, bubbling, no color difference, and high light working surface has strong adhesion, and the effect reaches the international leading level.

3. Low energy consumption: the total power of the machine is 18KW, which is one half of that of the peer equipment; The main heating starting power is 15KW, and the average power consumption is 8KW/h.

4. High configuration: the key part of the machine adopts original parts from Germany, Japan and Taiwan, which is high configuration and stable performance.

Upgrade improvements

u The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

u The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

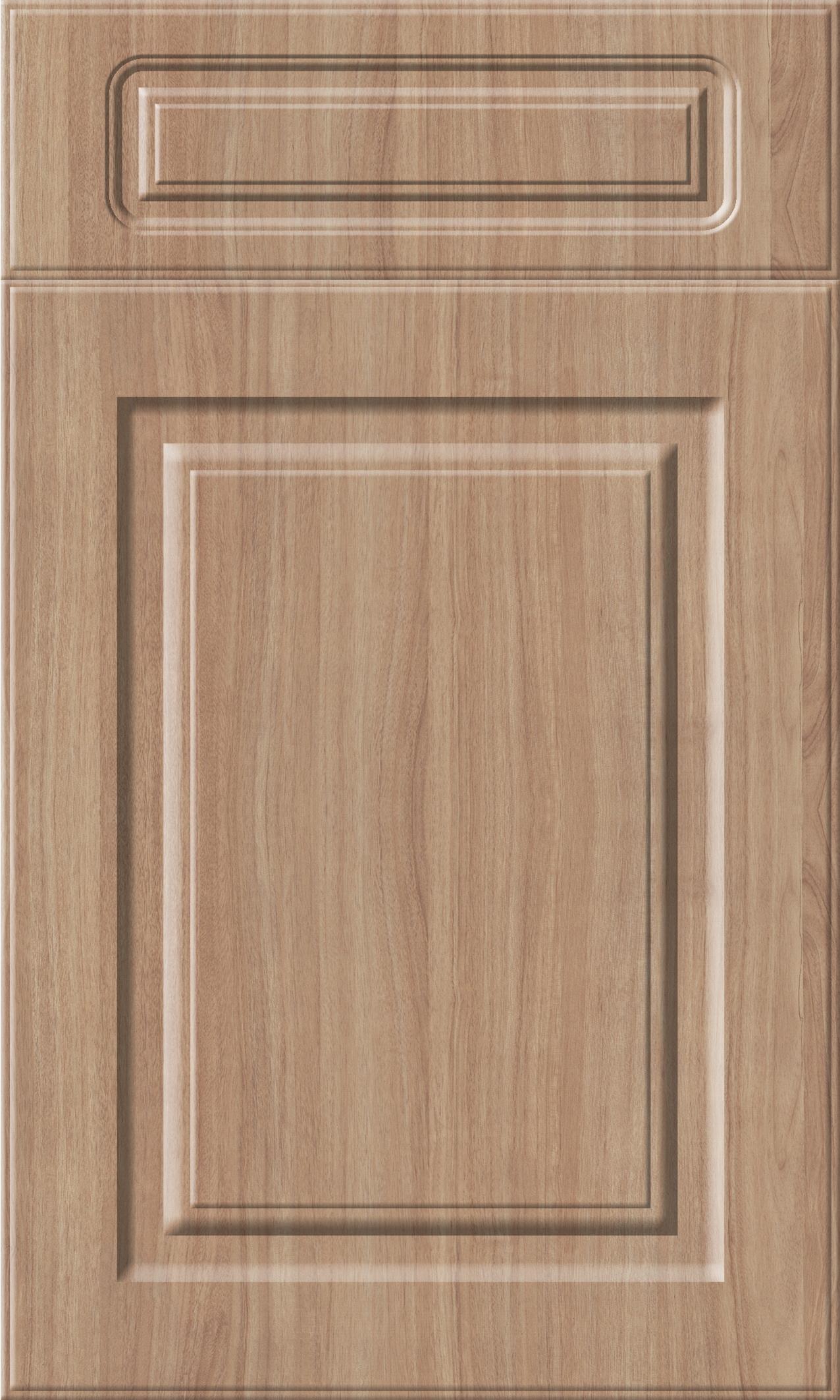

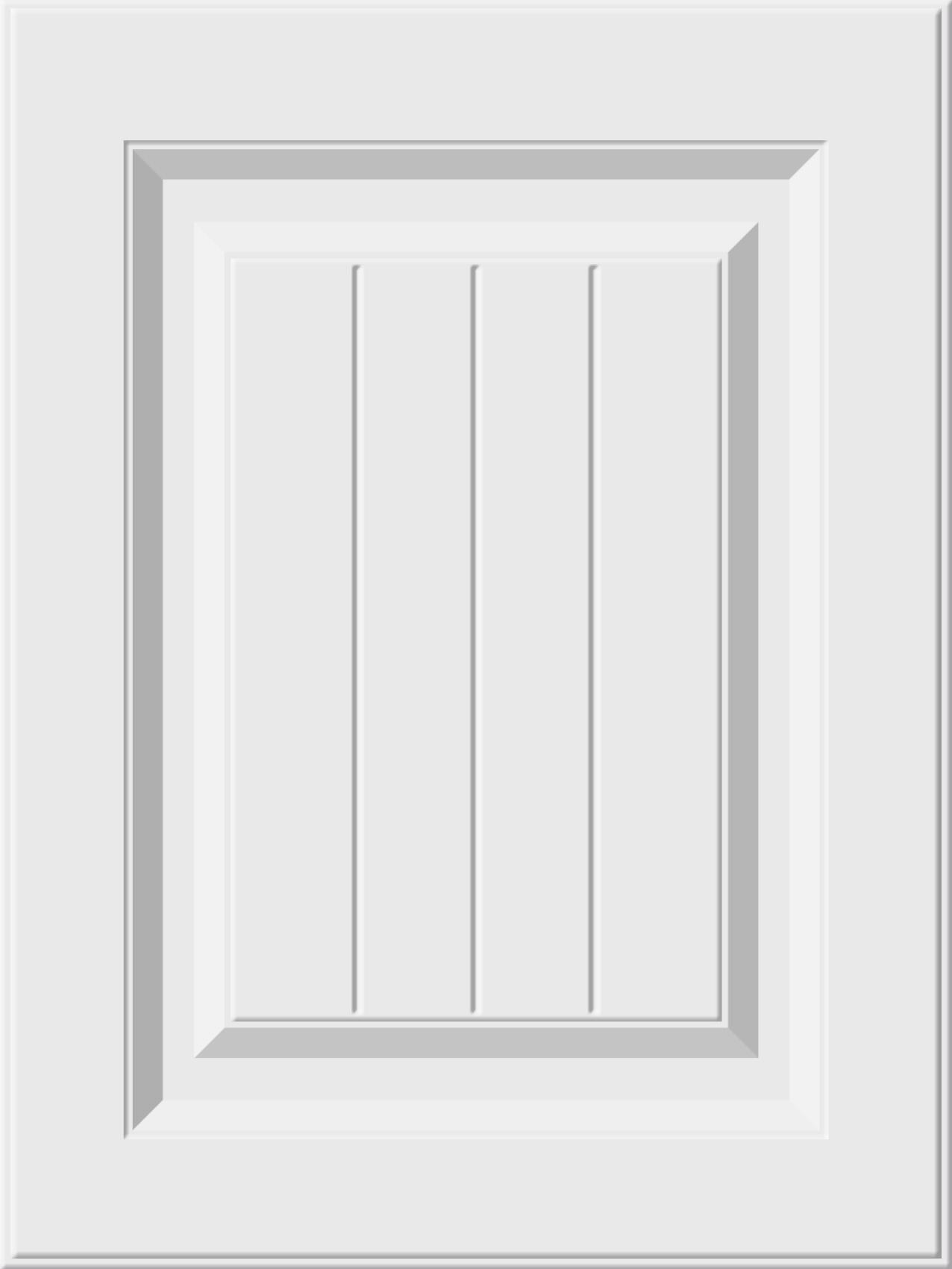

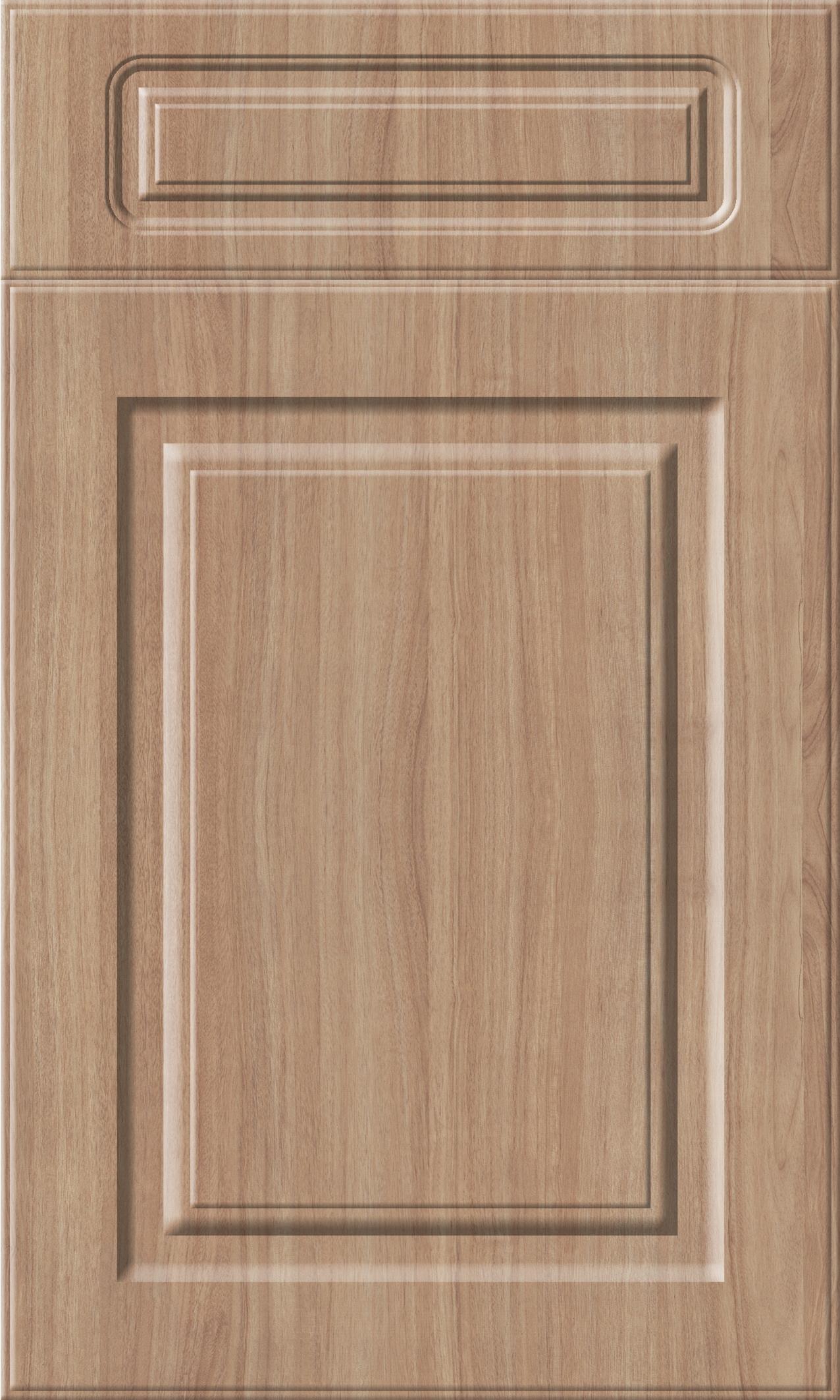

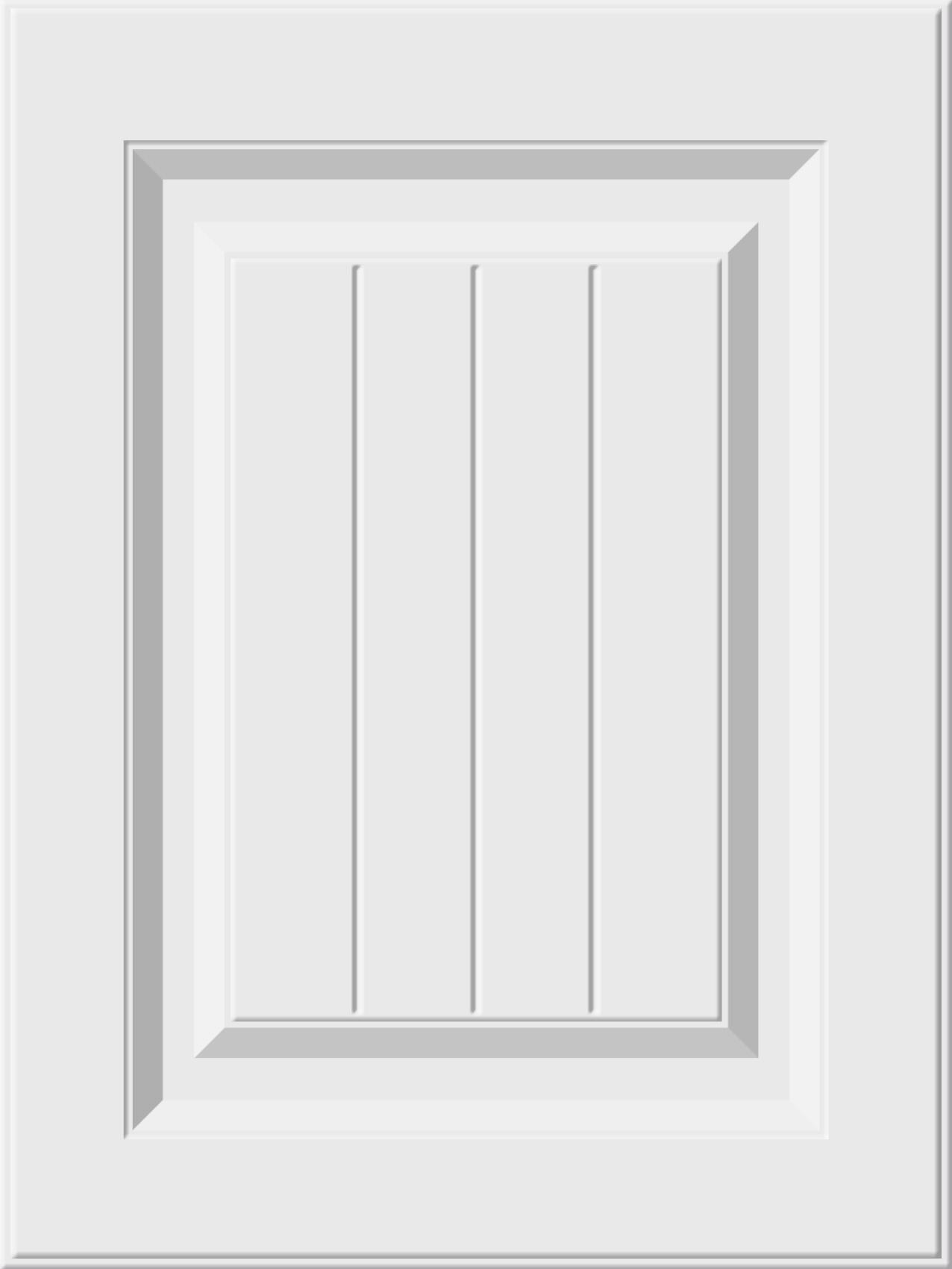

Workpiece Display

Electrical component list

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1 | 1 | Chint | ||||

3 | ammeter | 85L1 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

Component display

Solid 180mm cylinder Rack blasting Lifting system

Upper tray PVC bracket Aluminum frame

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

How it works

This machine adopts human-computer interface, easy to understand and operate, automatic double-station machine

Preheating equipment

Put product on the workbench

Pull the PVC membrane and cover cabinet door

Cutting membrane

Enter the machine

The membrane floating up and heating

Vacuum plus negative pressure plus positive pressure

Release of positive and negative pressure

Unloading hydraulic

Drop workbench

Workbench out

Work end

This process is done automatically by one click

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Silicone plate size

This machine is equipped with a silicone plate size of 1.75m*3.05m 3T (thickness)

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Click here to contact Michelle on Facebook

Quality and Service are most important things for us

If you have any problem,please let us know

Vacuum Upper Pressure Membrane Machine Specification

Features

1. Fast speed: the working period of ordinary workpiece is less than 2 minutes after it enters the main machine, which is 2-4 times of the efficiency of common positive and negative pressure membrane pressure equipment.

2. Good effect: the product processed by common film has clear groove, no open side, bubbling, no color difference, and high light working surface has strong adhesion, and the effect reaches the international leading level.

3. Low energy consumption: the total power of the machine is 18KW, which is one half of that of the peer equipment; The main heating starting power is 15KW, and the average power consumption is 8KW/h.

4. High configuration: the key part of the machine adopts original parts from Germany, Japan and Taiwan, which is high configuration and stable performance.

Upgrade improvements

u The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

u The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Workpiece Display

Electrical component list

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1 | 1 | Chint | ||||

3 | ammeter | 85L1 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

Component display

Solid 180mm cylinder Rack blasting Lifting system

Upper tray PVC bracket Aluminum frame

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

How it works

This machine adopts human-computer interface, easy to understand and operate, automatic double-station machine

Preheating equipment

Put product on the workbench

Pull the PVC membrane and cover cabinet door

Cutting membrane

Enter the machine

The membrane floating up and heating

Vacuum plus negative pressure plus positive pressure

Release of positive and negative pressure

Unloading hydraulic

Drop workbench

Workbench out

Work end

This process is done automatically by one click

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Silicone plate size

This machine is equipped with a silicone plate size of 1.75m*3.05m 3T (thickness)

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Click here to contact Michelle on Facebook

Quality and Service are most important things for us

If you have any problem,please let us know