- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

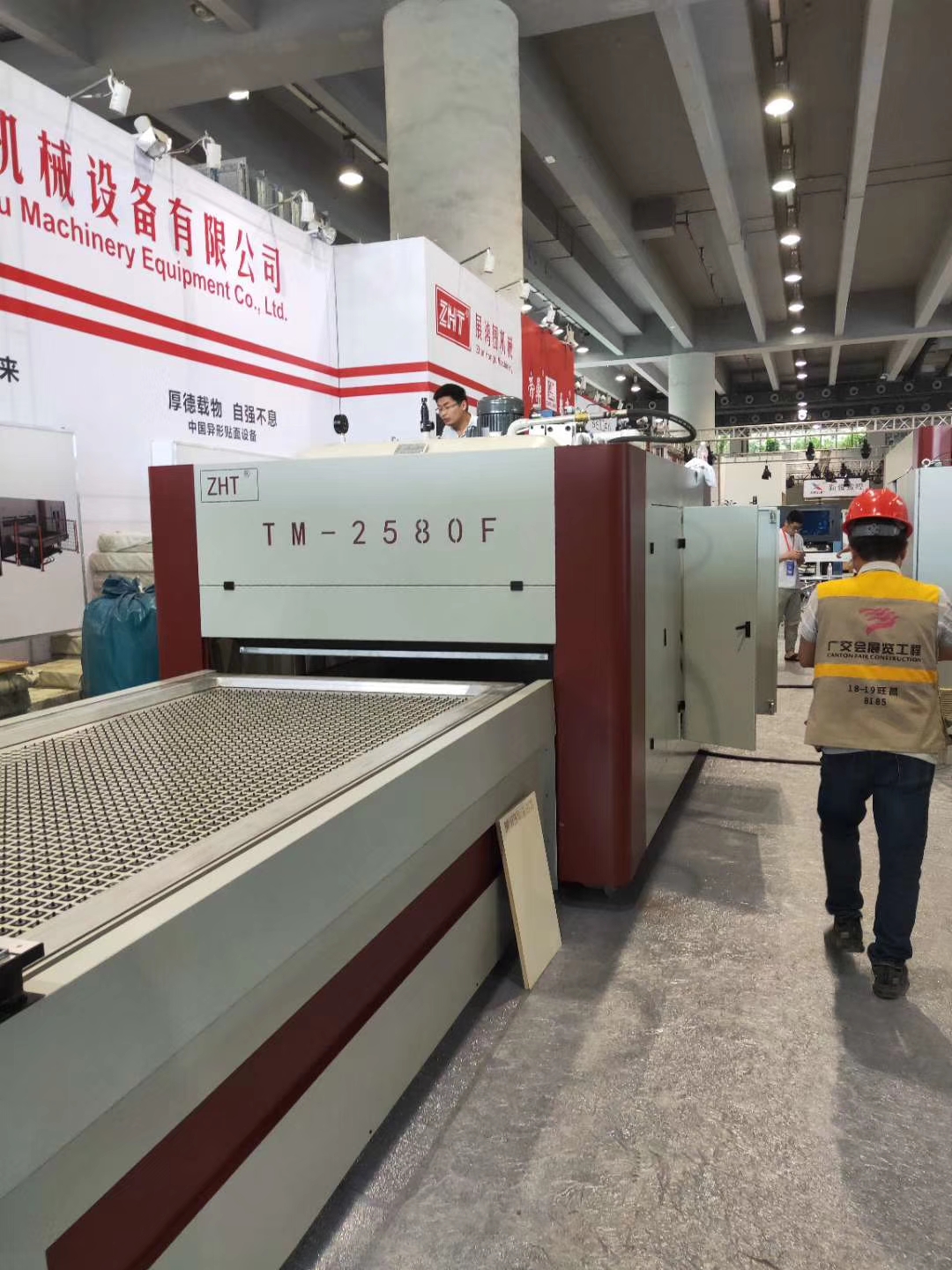

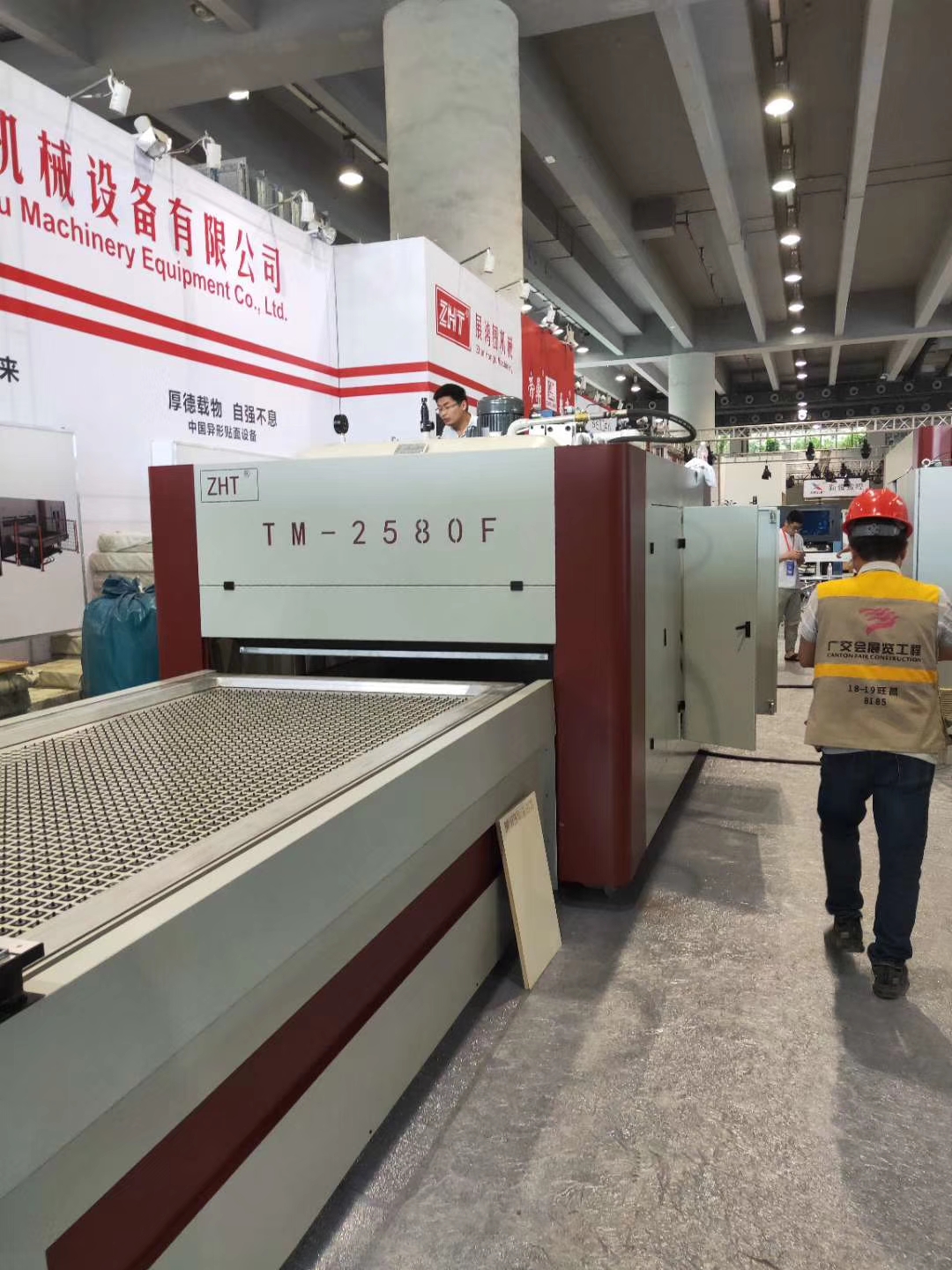

TM2580F-P

ZHT

Thermofoil Vacuum Press Machine with Pin Support System

Equipment characteristics:

1. Fast speed: the working period of highlight and ordinary workpieces entering the host to come out is within 2 minutes, which is 2-4 times the efficiency of ordinary positive and negative pressure membrane pressure equipment;

2. Good effect: The finished products of ordinary film have clear grooves in place, no open edges, blisters, no color difference, strong adhesion of high-gloss work surface, and the effect reaches the international leading level.

3. Low energy consumption: the heating power of this machine is 28KW, which is one-half of the power of peer equipment; the main heating start power is 21 KW, and the average power consumption is about 10KW/h

4. High configuration: The key parts of the machine are made of original components from Germany, Japan and Taiwan, with high configuration and stable performance;

5. The whole machine can be equipped with the automatic top block of the upgrade table, which saves the process of making the pad plate compared with other domestic equipment, and saves the cost of raw materials for the process. The technology can be adapted to different manufacturers and different positive and negative pressure equipment, saving the cost of replacing equipment. The sequence of scanning actions of the equipment pads is omitted, and the time for laminating is saved, which greatly improves work efficiency and reduces labor costs.

6. Manpower requires 3 people, one trimming and two swing boards. Large production capacity: standard operation 270-300 square meters/day, non-standard operation 210-250 square meters/day.

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Upgrade improvements

u The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

u The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

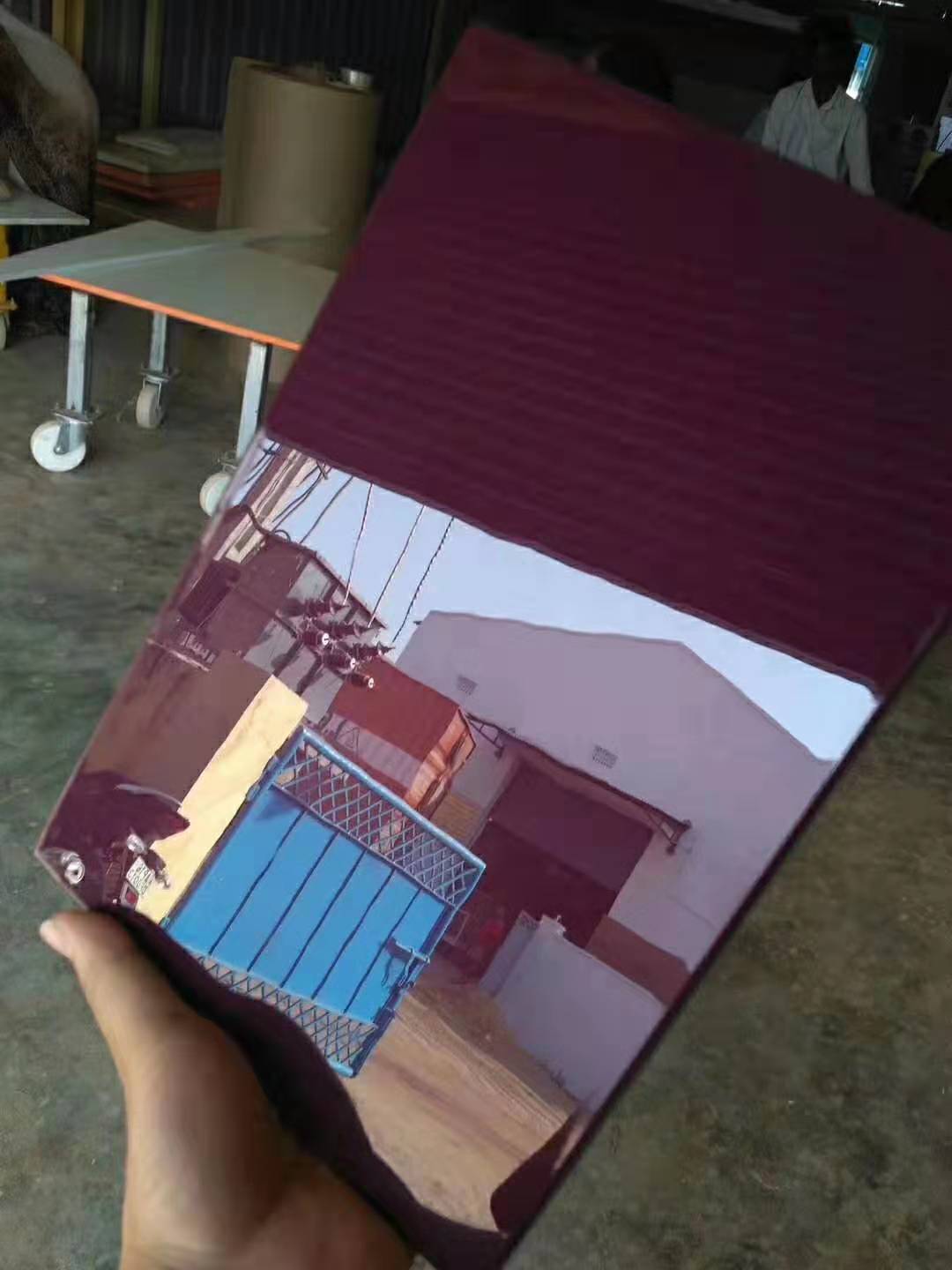

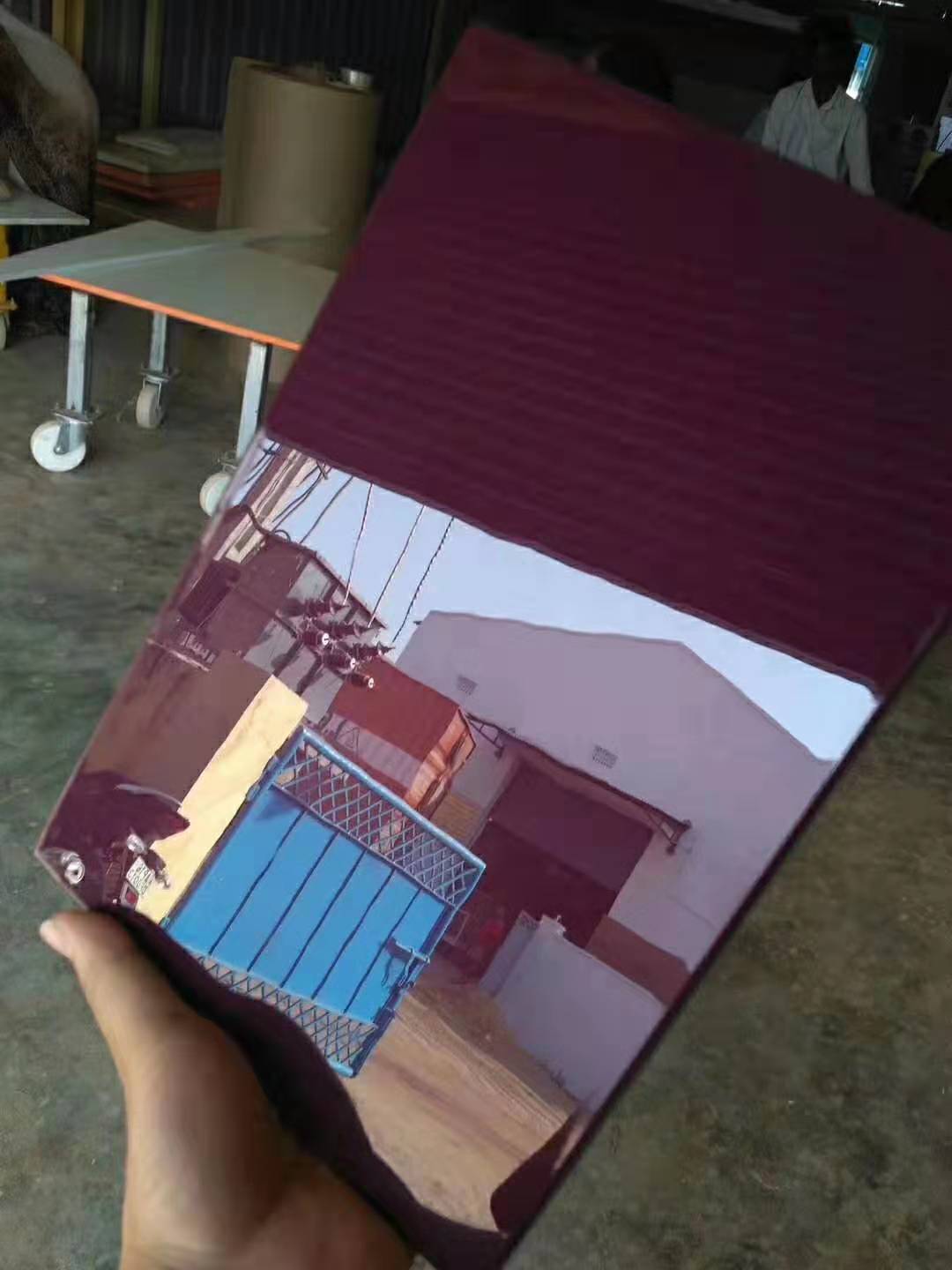

Workpiece Display

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Silicone plate size

This machine is equipped with a silicone plate size of 1.75m*3.05m 3T (thickness)

Quality and Service are most important things for us

If you have any problem,please let us know

Thermofoil Vacuum Press Machine with Pin Support System

Equipment characteristics:

1. Fast speed: the working period of highlight and ordinary workpieces entering the host to come out is within 2 minutes, which is 2-4 times the efficiency of ordinary positive and negative pressure membrane pressure equipment;

2. Good effect: The finished products of ordinary film have clear grooves in place, no open edges, blisters, no color difference, strong adhesion of high-gloss work surface, and the effect reaches the international leading level.

3. Low energy consumption: the heating power of this machine is 28KW, which is one-half of the power of peer equipment; the main heating start power is 21 KW, and the average power consumption is about 10KW/h

4. High configuration: The key parts of the machine are made of original components from Germany, Japan and Taiwan, with high configuration and stable performance;

5. The whole machine can be equipped with the automatic top block of the upgrade table, which saves the process of making the pad plate compared with other domestic equipment, and saves the cost of raw materials for the process. The technology can be adapted to different manufacturers and different positive and negative pressure equipment, saving the cost of replacing equipment. The sequence of scanning actions of the equipment pads is omitted, and the time for laminating is saved, which greatly improves work efficiency and reduces labor costs.

6. Manpower requires 3 people, one trimming and two swing boards. Large production capacity: standard operation 270-300 square meters/day, non-standard operation 210-250 square meters/day.

Technical parameter

Dimensions | 11200mm×2480mm×2150mm |

Bed dimension | 2560mm×1270mm |

Maximum machining height | 50mm |

Rated working pressure | positive pressure≤0.6Mpa negative pressure≥-0.095Mpa |

Total power | 28Kw |

Actual power consumption | about 10kw |

Total weight | 14T |

Power | 380V 50HZ |

Hardware Configuration

Rack | The whole steel plate is cutting |

Diameter of oil tank | 180mm |

Cylinder structure | Solid |

Cylinder structure | 200mm |

Hydraulic system | TaiWan |

Heating method | Electrical heating (nano technology) |

Vacuum pump(import) | SV100 |

Relay(import) | Schneider |

Upgrade improvements

u The equipment uses imported solid core diameter 180mm cylinder to prevent oil leakage.

u The frame is made of manganese steel plate and sandblasted to enhance corrosion resistance and load bearing.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

Workpiece Display

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Silicone plate size

This machine is equipped with a silicone plate size of 1.75m*3.05m 3T (thickness)

Quality and Service are most important things for us

If you have any problem,please let us know