- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

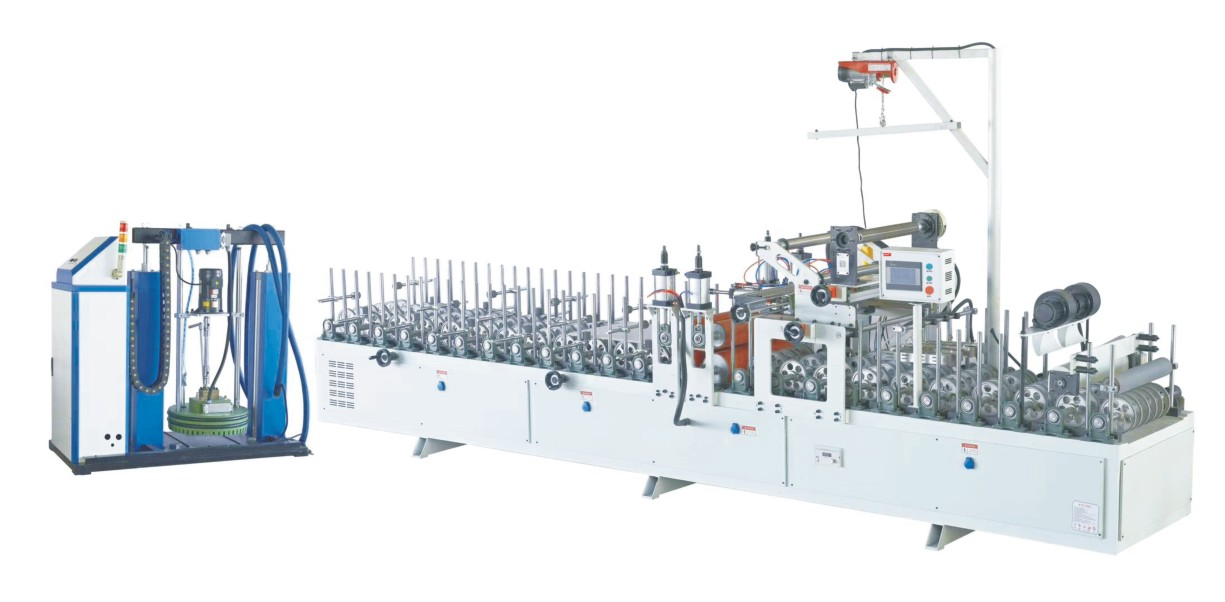

MBF-1300 PUR

ZHT

Configuration and functions

This machine can paste various decorative materials such as wood flakes, varnished paper, PVC film, etc. on the surface, side and bottom of flat and strip materials to achieve a perfect decorative effect.

The fuselage is welded by the national standard square steel and steel plate. After the aging treatment, the gantry milling is processed as a whole with high precision; the surface of the fuselage is sandblasted and rust-removed; the frame is sprayed with paint and the protective plate is sprayed with plastic;

Dedusting devices.

In the blowing device, some difficult-to-handle dust on the surface of the profile is blown off. The blowing device adopts a universal connection, and the blowing angle can be adjusted according to the actual working conditions.

The transmission method is worm gear, the diameter of the conveying shaft is φ40mm, and the distance between the shafts is 250mm. Each transmission shaft contains 9 transmission wheels. The diameter of the transmission wheel is φ200mm. The surface is hung with silica gel. The silicone roller with diameter φ200mm is attached to the main pressure roller.

The control operation screen adopts a touch screen and is equipped with a simplified diagram of the equipment flow, which can clearly observe the operation of the equipment; adopts PLC control and incorporates the functions of the melter equipment into the PLC. The equipment is equipped with inching forward and backward switches, the debugging operation is simple and convenient;

The melter adopts a pressure plate heating form; the heating temperature is controllable; the heating has an alarm function;

PUR glue supply control mode: the frequency converter drives the speed regulating AC motor to drive the gear pump to supply glue; the maximum speed of the motor: 125, the maximum glue supply of the PUR glue machine: 200kg/H;

The 55-gallon PUR hot-melt glue machine adopts touch button operation, the man-machine interface is simple and friendly, and the PUR hot-melt glue machine can be operated without complicated training. The 55-gallon PUR polyurethane hot-melt glue machine uses a precision metering pump to pump glue, PUR The hot melt glue machine is equipped with a motor speed curve setting and multi-stage PUR glue machine equipment protection. When the temperature of the heating plate of the PUR polyurethane hot melt glue machine does not reach the temperature set by the system, the main motor of the PUR polyurethane hot melt glue machine does not run to prevent Forcible operation causes damage to the pump body or motor; each throat of the 55-gallon PUR hot melt glue machine is equipped with an independent pressure control system, and the PUR hot melt glue machine adopts a standard 2-way hot melt glue hose and hose output, and two channels are reserved. Glue supply hose configuration can be expanded to 7 channels of PUR hot melt glue for glue dispensing;

The 55-gallon moisture-reactive PUR platen hot melt adhesive machine is equipped with a temperature control meter to control the temperature of the system, saving customer costs. The polyurethane PUR hot melt adhesive machine has multi-stage temperature control, and the temperature control is accurate to plus or minus 1 degrees Celsius. PUR hot melt The internal electrical and mechanical protection functions of the melter are complete, the upper and lower limit alarm settings of the polyurethane hot melt glue sol temperature, the hot melt glue machine temperature sensor damage alarm, the PUR hot melt glue machine heater damage alarm, precise and stable control of the polyurethane hot melt glue machine The work of 55 gallons of PUR hot melt glue tank glue level detection and alarm function, PUR hot melt glue machine with intelligent fault location and other functions, PUR hot melt glue machine spraying equipment suitable for PUR hot melt glue spraying, international standard 55 gallons When using barreled PUR hot melt adhesive;

PUR pressure plate hot melt glue machine glue position indication function: the unique glue quantity reminder function is designed in the 55 gallon PUR hot melt glue machine system, using green, yellow and red glue quantity indicator lights, and electronic alarm system, timely Accurately let you know the remaining amount of PUR glue in the glue bucket, and there will be a separate prompt system when the PUR hot melt glue in the glue bucket is used up;

Ⅱ. Technical Parameters

Outlined Size | 4760mm*2700mm*2800mm |

Width of PVC MATERIAL | 1300mm |

Maximum Working Height | 80mm |

Glue Applied | 1. 35-45g or so for PVC material per m2. 2. 60g or so for wooden veneer per m2. |

Width of Driving Wheel |

|

Feeding Speed | 0-30m/min.,Speed adjustment by frequency conversion |

Total Power | About 50kw |

Machine Weight | About 5T |

Ⅲ. Configuration selected:

Affinity agent and fluorescent lamp detection device (optional)

Affinity device

Before the profile enters the pressing, first use the affinity agent to apply the affinity agent to the parts to be processed to meet the bonding requirements during the profile pressing. The affinity agent flows into the felt roller from the temporary storage box and smears the surface of the profile; The felt roller is made of wool. The inner felt roller sleeve is provided with regular circular holes. The affinity agent penetrates into the felt roller through the inner felt roller sleeve and rolls on the surface of the sheet to ensure uniform application of the affinity agent. The flow rate of the affinity agent adopts a valve. Control the flow rate, easy to operate; the affinity agent temporary storage box is made of stainless steel, and the affinity agent connecting pipe is made of PTFE, which has corrosion resistance; the excess affinity agent flows to the recovery device through the affinity agent tray and is reused , Saving consumption;

Fluorescent lamp detection device

The coating uniformity of the affinity solution will directly affect the processing quality of the surface of the profile, so we must observe the working condition of the affinity solution in time. We use the TL8WBLB fluorescent lamp for detection. When the affinity solution mixed with phosphor passes through the fluorescent lamp After irradiation, we can see the application of the affinity solution with the naked eye;

Automatic cutting (optional) (optional automatic cutting costs increase by CNY 30,000 ).

Features and introduction:

1) Driven by servo motor with rack and pinion;

2) The encoder measures the length and cuts horizontally after reaching the set value;

3) Using the oblique cutting method, the cutting piece is cut from the gap between the transmission wheels

along the set angle;

4) The blade adopts cylinder to cooperate with linear guide to rise and fall;

5) The whole machine is integrated with the coating machine, and the power transmission of the coating

machine is adopted to ensure accurate cutting.

Vulnerable part:Silicone wheels (not covered by the warrant)

Delivery time: 45 working days.

Accessories Included

Items | Unit | Quantity |

17×19 Spanner | PCS | 1 |

12×14 Spanner | PCS | 1 |

PCS | 1 | |

PCS | 1 | |

PCS | 2 | |

PCS | 1 | |

PCS | 1 | |

25 double holes | PCS | 120 |

25 single hole | PCS | 60 |

25*300 connecting rod | Stick | 80 |

25*250 connecting rod | Stick | 40 |

25*250 long single hole | Stick | 12 |

50*30 plastic core-rubber-tires | PCS | 50 |

50*20 plastic core-rubber-tires | PCS | 50 |

R0.5 pointed roller | PCS | 6 |

77*15 pointed roller | PCS | 6 |

R1.3 | PCS | 6 |

R4 | PCS | 6 |

R5 | PCS | 6 |

R10 | PCS | 6 |

R15 | PCS | 6 |

R19.5 | PCS | 6 |

One-sided silicon pointed roller | PCS | 6 |

50*20 Inner arc | PCS | 6 |

60*10steps | PCS | 6 |

50*50 | PCS | 6 |

6 Heat Guns(matched 6 supports) | PCS | |

60*2 iron stepped roller | PCS | 3 |

Ⅶ Warranty, after-sales service and personnel training

In order to ensure that the purchaser can use the equipment normally, the warranty period is two years, except for consumables (silicone wheels). The supplier guarantees the equipment free of charge during the warranty period. Outside the warranty period, it provides free consultation and troubleshooting for repairs, maintenance, and faults. The warranty period starts from the day the device leaves the factory.

The warranty does not include: damage caused by man-made and natural disasters. (Such as fire, flood, earthquake).

If the equipment fails, the supplier shall rush to and solve the failure within 24 hours after receiving the notification from the buyer, and provide corresponding qualified parts and repairs free of charge during the warranty period; outside the warranty period, the supplier shall provide the buyer at a preferential price for a long time The costs incurred when the supplier comes to repair the relevant parts and components shall be settled through negotiation between the two parties.

The supplier sends technical personnel to the demand side to install and debug the cooperative equipment, and provide actual operation processing, repair and maintenance training to the demand side personnel.

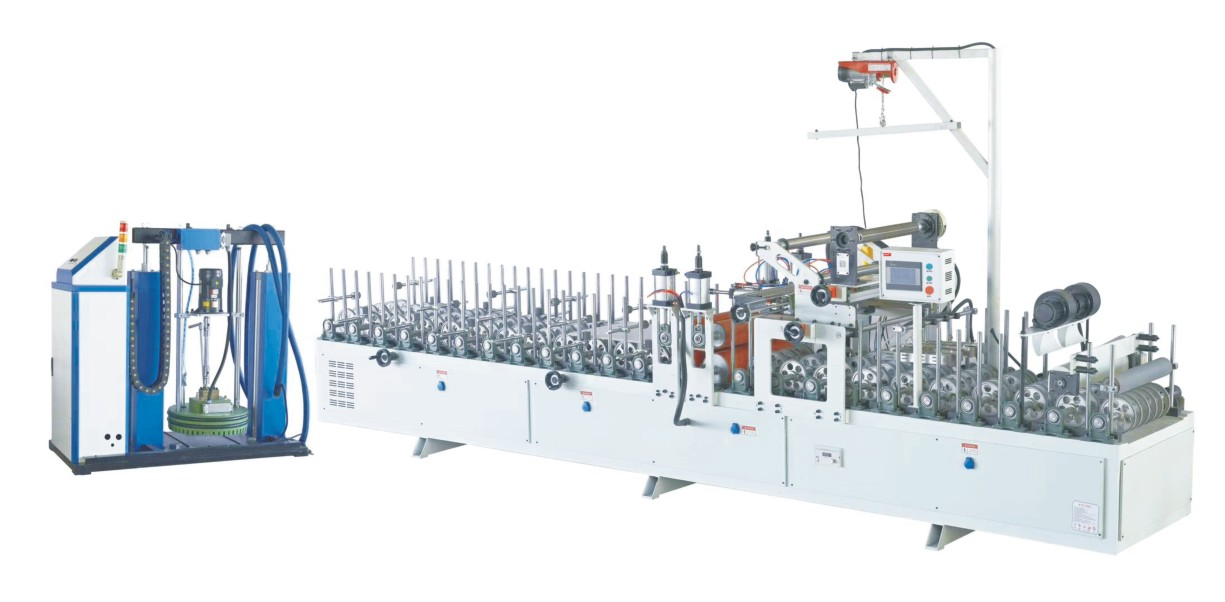

Configuration and functions

This machine can paste various decorative materials such as wood flakes, varnished paper, PVC film, etc. on the surface, side and bottom of flat and strip materials to achieve a perfect decorative effect.

The fuselage is welded by the national standard square steel and steel plate. After the aging treatment, the gantry milling is processed as a whole with high precision; the surface of the fuselage is sandblasted and rust-removed; the frame is sprayed with paint and the protective plate is sprayed with plastic;

Dedusting devices.

In the blowing device, some difficult-to-handle dust on the surface of the profile is blown off. The blowing device adopts a universal connection, and the blowing angle can be adjusted according to the actual working conditions.

The transmission method is worm gear, the diameter of the conveying shaft is φ40mm, and the distance between the shafts is 250mm. Each transmission shaft contains 9 transmission wheels. The diameter of the transmission wheel is φ200mm. The surface is hung with silica gel. The silicone roller with diameter φ200mm is attached to the main pressure roller.

The control operation screen adopts a touch screen and is equipped with a simplified diagram of the equipment flow, which can clearly observe the operation of the equipment; adopts PLC control and incorporates the functions of the melter equipment into the PLC. The equipment is equipped with inching forward and backward switches, the debugging operation is simple and convenient;

The melter adopts a pressure plate heating form; the heating temperature is controllable; the heating has an alarm function;

PUR glue supply control mode: the frequency converter drives the speed regulating AC motor to drive the gear pump to supply glue; the maximum speed of the motor: 125, the maximum glue supply of the PUR glue machine: 200kg/H;

The 55-gallon PUR hot-melt glue machine adopts touch button operation, the man-machine interface is simple and friendly, and the PUR hot-melt glue machine can be operated without complicated training. The 55-gallon PUR polyurethane hot-melt glue machine uses a precision metering pump to pump glue, PUR The hot melt glue machine is equipped with a motor speed curve setting and multi-stage PUR glue machine equipment protection. When the temperature of the heating plate of the PUR polyurethane hot melt glue machine does not reach the temperature set by the system, the main motor of the PUR polyurethane hot melt glue machine does not run to prevent Forcible operation causes damage to the pump body or motor; each throat of the 55-gallon PUR hot melt glue machine is equipped with an independent pressure control system, and the PUR hot melt glue machine adopts a standard 2-way hot melt glue hose and hose output, and two channels are reserved. Glue supply hose configuration can be expanded to 7 channels of PUR hot melt glue for glue dispensing;

The 55-gallon moisture-reactive PUR platen hot melt adhesive machine is equipped with a temperature control meter to control the temperature of the system, saving customer costs. The polyurethane PUR hot melt adhesive machine has multi-stage temperature control, and the temperature control is accurate to plus or minus 1 degrees Celsius. PUR hot melt The internal electrical and mechanical protection functions of the melter are complete, the upper and lower limit alarm settings of the polyurethane hot melt glue sol temperature, the hot melt glue machine temperature sensor damage alarm, the PUR hot melt glue machine heater damage alarm, precise and stable control of the polyurethane hot melt glue machine The work of 55 gallons of PUR hot melt glue tank glue level detection and alarm function, PUR hot melt glue machine with intelligent fault location and other functions, PUR hot melt glue machine spraying equipment suitable for PUR hot melt glue spraying, international standard 55 gallons When using barreled PUR hot melt adhesive;

PUR pressure plate hot melt glue machine glue position indication function: the unique glue quantity reminder function is designed in the 55 gallon PUR hot melt glue machine system, using green, yellow and red glue quantity indicator lights, and electronic alarm system, timely Accurately let you know the remaining amount of PUR glue in the glue bucket, and there will be a separate prompt system when the PUR hot melt glue in the glue bucket is used up;

Ⅱ. Technical Parameters

Outlined Size | 4760mm*2700mm*2800mm |

Width of PVC MATERIAL | 1300mm |

Maximum Working Height | 80mm |

Glue Applied | 1. 35-45g or so for PVC material per m2. 2. 60g or so for wooden veneer per m2. |

Width of Driving Wheel |

|

Feeding Speed | 0-30m/min.,Speed adjustment by frequency conversion |

Total Power | About 50kw |

Machine Weight | About 5T |

Ⅲ. Configuration selected:

Affinity agent and fluorescent lamp detection device (optional)

Affinity device

Before the profile enters the pressing, first use the affinity agent to apply the affinity agent to the parts to be processed to meet the bonding requirements during the profile pressing. The affinity agent flows into the felt roller from the temporary storage box and smears the surface of the profile; The felt roller is made of wool. The inner felt roller sleeve is provided with regular circular holes. The affinity agent penetrates into the felt roller through the inner felt roller sleeve and rolls on the surface of the sheet to ensure uniform application of the affinity agent. The flow rate of the affinity agent adopts a valve. Control the flow rate, easy to operate; the affinity agent temporary storage box is made of stainless steel, and the affinity agent connecting pipe is made of PTFE, which has corrosion resistance; the excess affinity agent flows to the recovery device through the affinity agent tray and is reused , Saving consumption;

Fluorescent lamp detection device

The coating uniformity of the affinity solution will directly affect the processing quality of the surface of the profile, so we must observe the working condition of the affinity solution in time. We use the TL8WBLB fluorescent lamp for detection. When the affinity solution mixed with phosphor passes through the fluorescent lamp After irradiation, we can see the application of the affinity solution with the naked eye;

Automatic cutting (optional) (optional automatic cutting costs increase by CNY 30,000 ).

Features and introduction:

1) Driven by servo motor with rack and pinion;

2) The encoder measures the length and cuts horizontally after reaching the set value;

3) Using the oblique cutting method, the cutting piece is cut from the gap between the transmission wheels

along the set angle;

4) The blade adopts cylinder to cooperate with linear guide to rise and fall;

5) The whole machine is integrated with the coating machine, and the power transmission of the coating

machine is adopted to ensure accurate cutting.

Vulnerable part:Silicone wheels (not covered by the warrant)

Delivery time: 45 working days.

Accessories Included

Items | Unit | Quantity |

17×19 Spanner | PCS | 1 |

12×14 Spanner | PCS | 1 |

PCS | 1 | |

PCS | 1 | |

PCS | 2 | |

PCS | 1 | |

PCS | 1 | |

25 double holes | PCS | 120 |

25 single hole | PCS | 60 |

25*300 connecting rod | Stick | 80 |

25*250 connecting rod | Stick | 40 |

25*250 long single hole | Stick | 12 |

50*30 plastic core-rubber-tires | PCS | 50 |

50*20 plastic core-rubber-tires | PCS | 50 |

R0.5 pointed roller | PCS | 6 |

77*15 pointed roller | PCS | 6 |

R1.3 | PCS | 6 |

R4 | PCS | 6 |

R5 | PCS | 6 |

R10 | PCS | 6 |

R15 | PCS | 6 |

R19.5 | PCS | 6 |

One-sided silicon pointed roller | PCS | 6 |

50*20 Inner arc | PCS | 6 |

60*10steps | PCS | 6 |

50*50 | PCS | 6 |

6 Heat Guns(matched 6 supports) | PCS | |

60*2 iron stepped roller | PCS | 3 |

Ⅶ Warranty, after-sales service and personnel training

In order to ensure that the purchaser can use the equipment normally, the warranty period is two years, except for consumables (silicone wheels). The supplier guarantees the equipment free of charge during the warranty period. Outside the warranty period, it provides free consultation and troubleshooting for repairs, maintenance, and faults. The warranty period starts from the day the device leaves the factory.

The warranty does not include: damage caused by man-made and natural disasters. (Such as fire, flood, earthquake).

If the equipment fails, the supplier shall rush to and solve the failure within 24 hours after receiving the notification from the buyer, and provide corresponding qualified parts and repairs free of charge during the warranty period; outside the warranty period, the supplier shall provide the buyer at a preferential price for a long time The costs incurred when the supplier comes to repair the relevant parts and components shall be settled through negotiation between the two parties.

The supplier sends technical personnel to the demand side to install and debug the cooperative equipment, and provide actual operation processing, repair and maintenance training to the demand side personnel.