- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

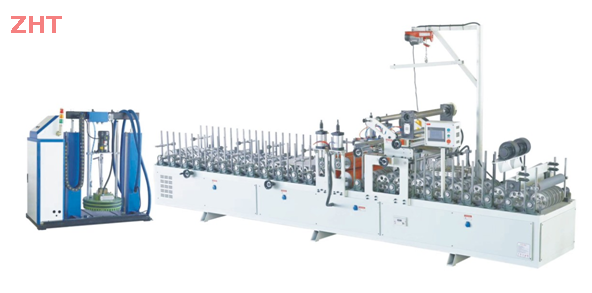

MBF-1300 PUR

ZHT

MBF-1300 PUR

MBF-1300 PUR Hot Glue Wrapping Machine (PUR)

I. Technical Parameters:

Outlined Size: 4760mm * 2700mm * 2800mm

Width of PVC Material: 1300mm

Maximum Working Height: 80mm

Glue Applied:

35-45g or so for PVC material per m².

60g or so for wooden veneer per m².

Width of Driving Wheel: 15mm

Feeding Speed: 0-30m/min (Speed adjustment by frequency conversion)

Total Power: About 50kw

Machine Weight: About 5T

II. Configuration and Functions:

The machine can apply various decorative materials on flat and strip materials to achieve perfect decorative effects.

The fuselage is welded using national standard square steel and steel plate, with high precision after aging treatment and gantry milling. The surface undergoes sandblasting, rust removal, paint spraying, and plastic spraying.

Dedusting devices for blowing off difficult-to-handle dust on the profile surface. The blowing device uses a universal connection with adjustable blowing angles.

Transmission method is worm gear, conveying shaft diameter is φ40mm, each shaft contains 9 transmission wheels with φ200mm diameter, silica gel coating. Silicone roller with φ200mm diameter is attached to the main pressure roller.

Control operation screen with touch screen and PLC control. Inch forward and backward switches for easy debugging.

Melter with pressure plate heating, controllable heating temperature, and alarm function.

PUR glue supply controlled by frequency converter-driven AC motor and gear pump. Maximum motor speed: 125, maximum glue supply: 200kg/h.

55-gallon PUR hot-melt glue machine with touch button operation, precision metering pump, motor speed curve setting, multi-stage equipment protection, and glue position indication function.

III. Configuration Selected:

Affinity Agent and Fluorescent Lamp Detection Device (Optional)

Affinity Agent Device: Applies affinity agent before profile pressing for bonding. Felt roller made of wool with controlled flow rate. Stainless steel temporary storage box and PTFE corrosion-resistant connecting pipe.

Fluorescent Lamp Detection Device: Uses TL8WBLB fluorescent lamp to detect coating uniformity of affinity solution.

Automatic Cutting (Optional)

Driven by a servo motor with rack and pinion.

Encoder measures length for horizontal cutting.

Uses oblique cutting method, and blade rises and falls using a cylinder.

Integrated with the coating machine, ensuring accurate cutting.

IV. Vulnerable Part: Silicone wheels (not covered by the warranty)

V. Delivery Time: 45 working days

VI. Accessories Included:

Various wrenches

Allen wrenches

Connecting rods

Plastic core-rubber tires

Pointed and sharp rollers of different sizes

Inner arc wheels

Steps wheels

Heat guns

Iron stepped rollers

VII. Warranty, After-sales Service, and Personnel Training:

Two-year warranty, excluding consumables (silicone wheels). Free equipment warranty during the warranty period with free consultation and troubleshooting for repairs, maintenance, and faults during the non-warranty period.

Exclusions: Damage caused by man-made and natural disasters.

Supplier provides quick response to failures within 24 hours during the warranty period, offering free qualified parts and repairs. Outside the warranty period, the supplier provides maintenance at a preferential price.

Technical personnel sent for installation, debugging, and training demand-side personnel in actual operation, processing, repair, and maintenance.

If you have any problems, please let us know.

If you have any problems, please let us know.

Quality and service are the most important things for us.

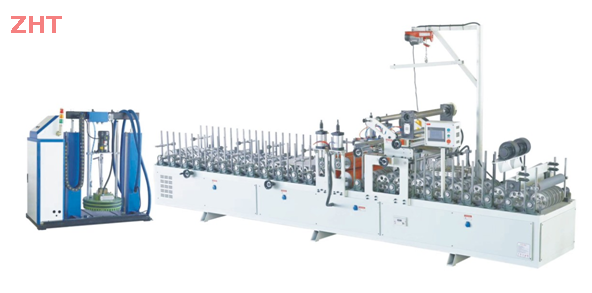

MBF-1300 PUR Hot Glue Wrapping Machine (PUR)

I. Technical Parameters:

Outlined Size: 4760mm * 2700mm * 2800mm

Width of PVC Material: 1300mm

Maximum Working Height: 80mm

Glue Applied:

35-45g or so for PVC material per m².

60g or so for wooden veneer per m².

Width of Driving Wheel: 15mm

Feeding Speed: 0-30m/min (Speed adjustment by frequency conversion)

Total Power: About 50kw

Machine Weight: About 5T

II. Configuration and Functions:

The machine can apply various decorative materials on flat and strip materials to achieve perfect decorative effects.

The fuselage is welded using national standard square steel and steel plate, with high precision after aging treatment and gantry milling. The surface undergoes sandblasting, rust removal, paint spraying, and plastic spraying.

Dedusting devices for blowing off difficult-to-handle dust on the profile surface. The blowing device uses a universal connection with adjustable blowing angles.

Transmission method is worm gear, conveying shaft diameter is φ40mm, each shaft contains 9 transmission wheels with φ200mm diameter, silica gel coating. Silicone roller with φ200mm diameter is attached to the main pressure roller.

Control operation screen with touch screen and PLC control. Inch forward and backward switches for easy debugging.

Melter with pressure plate heating, controllable heating temperature, and alarm function.

PUR glue supply controlled by frequency converter-driven AC motor and gear pump. Maximum motor speed: 125, maximum glue supply: 200kg/h.

55-gallon PUR hot-melt glue machine with touch button operation, precision metering pump, motor speed curve setting, multi-stage equipment protection, and glue position indication function.

III. Configuration Selected:

Affinity Agent and Fluorescent Lamp Detection Device (Optional)

Affinity Agent Device: Applies affinity agent before profile pressing for bonding. Felt roller made of wool with controlled flow rate. Stainless steel temporary storage box and PTFE corrosion-resistant connecting pipe.

Fluorescent Lamp Detection Device: Uses TL8WBLB fluorescent lamp to detect coating uniformity of affinity solution.

Automatic Cutting (Optional)

Driven by a servo motor with rack and pinion.

Encoder measures length for horizontal cutting.

Uses oblique cutting method, and blade rises and falls using a cylinder.

Integrated with the coating machine, ensuring accurate cutting.

IV. Vulnerable Part: Silicone wheels (not covered by the warranty)

V. Delivery Time: 45 working days

VI. Accessories Included:

Various wrenches

Allen wrenches

Connecting rods

Plastic core-rubber tires

Pointed and sharp rollers of different sizes

Inner arc wheels

Steps wheels

Heat guns

Iron stepped rollers

VII. Warranty, After-sales Service, and Personnel Training:

Two-year warranty, excluding consumables (silicone wheels). Free equipment warranty during the warranty period with free consultation and troubleshooting for repairs, maintenance, and faults during the non-warranty period.

Exclusions: Damage caused by man-made and natural disasters.

Supplier provides quick response to failures within 24 hours during the warranty period, offering free qualified parts and repairs. Outside the warranty period, the supplier provides maintenance at a preferential price.

Technical personnel sent for installation, debugging, and training demand-side personnel in actual operation, processing, repair, and maintenance.

If you have any problems, please let us know.

If you have any problems, please let us know.

Quality and service are the most important things for us.