- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

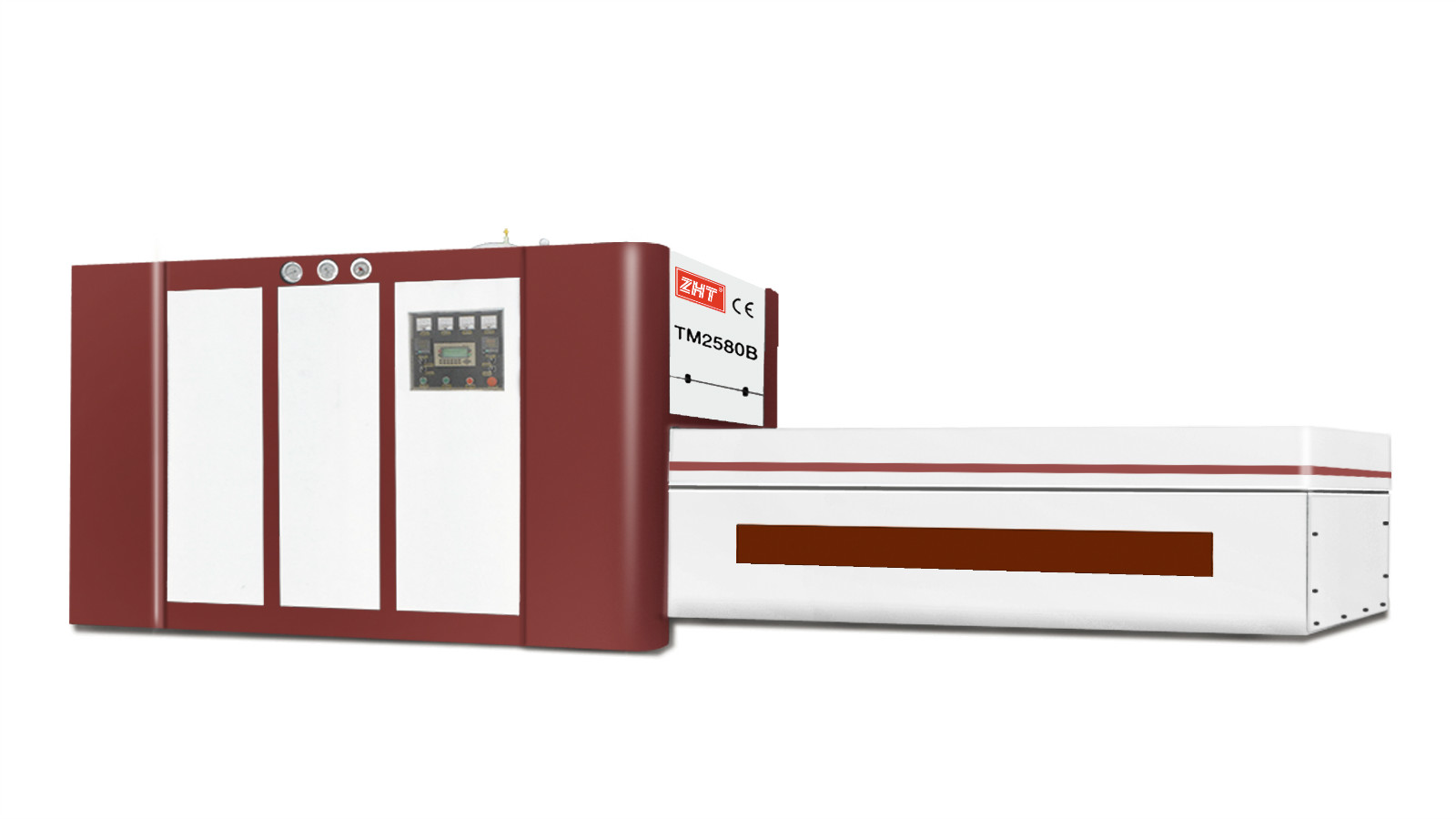

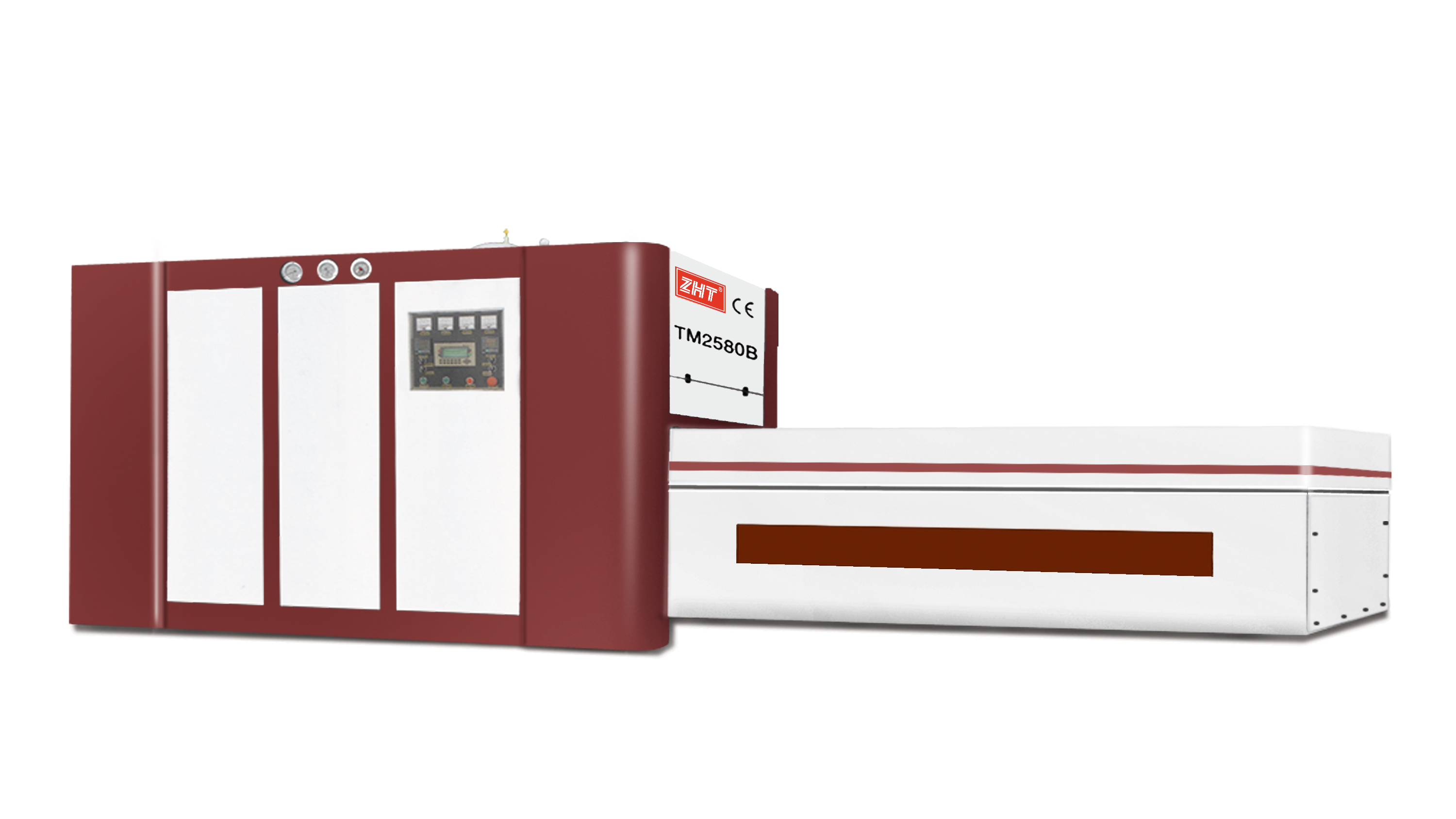

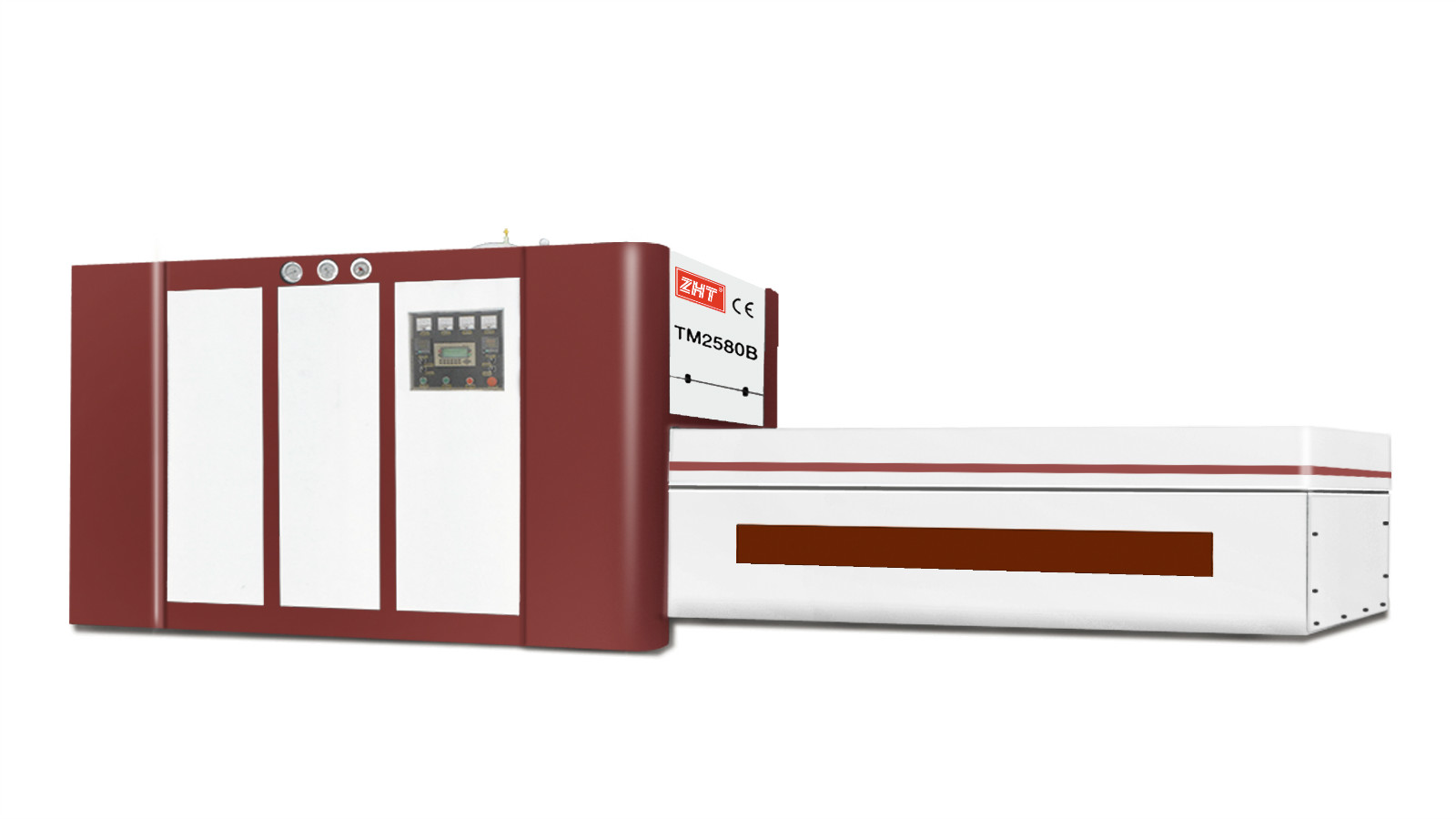

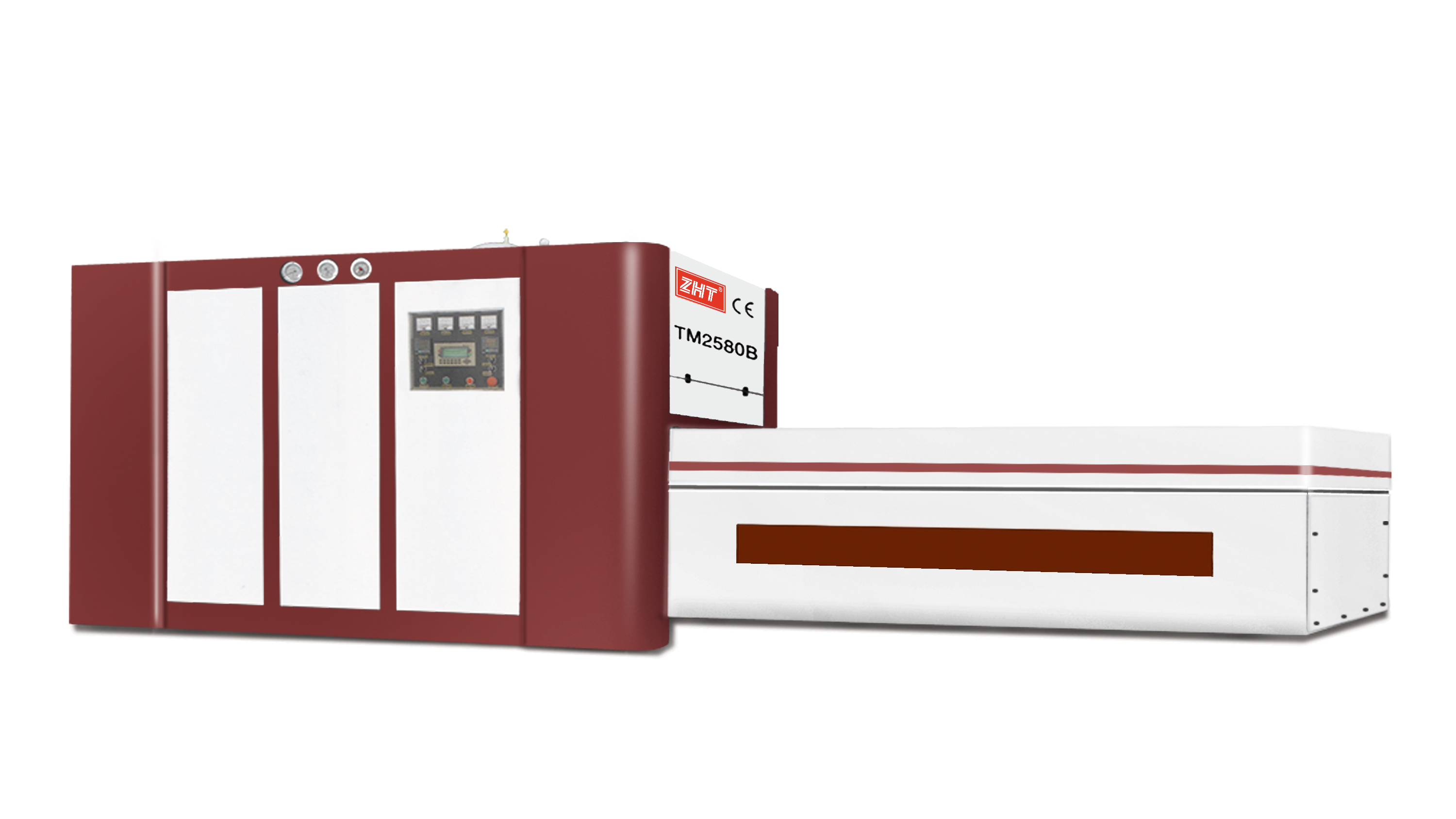

TM2580B

ZHT

PVC Veneer Vacuum Membrane Laminating Press Machine

Introduction

It is used to work various high-profile PVC, hot transfer and single veneer

All kinds of PVC workpieces processed by this machine stick firmly, do not bounce off the edge.Line of groove is clear and in place.

Feature

The operating system adopts imported brand PLC control, which is convenient to control, advanced technology and high automation.

Household electrical appliances used in electrical system contactor use imported components, low fault rate.

The main engine of the hydraulic system USES Taiwan system, the motor and the oil pump USES Taiwan KOMPASS, the hydraulic system principle is the board type interpolation, the international advanced structure, the fault rate is low, the large flow, the pressure is rapid, effectively improves the production efficiency.

Equipment is added wrinkle resistant PVC, greatly improve the yield of the product, higher than that of normal pressure yield of 15-20 ℅.

Technical parameter

| Dimensions | 6400mm*1900mm*2150mm |

| Bed dimension | 2300mm*1100mm(inner diameter) |

| Maximum machining height | 50mm |

| Rated working pressure | positive pressure ≤0.4Mpa negative pressure≥-0.095Mpa |

| Total power | 23KW |

| Actual power consumption | About 6KW |

| Total weight | 11T |

Upgrade improvements

u The walking guide is made in Taiwan, and the workbench walks more smoothly.

u The racks are all sandblasted to enhance corrosion resistance.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

Component display

Electric component Air tank

Host housing Frame

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1型 | 1 | Chint | ||||

3 | ammeter | 85L1型 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

How it works

This machine adopts human-computer interface, easy to understand and operate, automatic double-station machine

v Preheating equipment

v Put product on the workbench

v Pull the PVC membrane and cover cabinet door

v Cutting membrane

v Enter the machine

v The membrane floating up and heating

v Vacuum plus negative pressure plus positive pressure

v Release of positive and negative pressure

v Unloading hydraulic

v Drop workbench

v Workbench out

v Flipped board sucking sample up

v Cut membrane

v Work end

This process is done automatically by one click

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Differences from other machine

1. Low energy consumption: The press adopts nano heating mode, which has heat conduction heating and infrared radiation heating at the same time. The heating power per hour is about 10KW, which saves half of the electricity cost compared with other manufacturers. And the heating is even and reliable.

2, work efficiency: high yield of coated workpieces, fast work cycle, short cycle, a film finished product process is about 3 minutes and a half.

3, reduce labor costs: the machine operators always need 3-4 people, is one-half of the peer equipment. There are 2 people in the table, 1 person in the station (1 person can be borrowed from the table), 1 person in the trimming position; 6 people in the same position, 2 people in the table, 1 person in the station, pull The film position is 2 people, and the trimming position is 1 person.

4, large capacity: standard operation 350-400 flat / day, peers are 320-360 flat / day; non-standard operation 230-270 flat / day, peers are 200-240 flat / day.

5. The lifting of the top block is faster: the top block can realize the locking of the corresponding height due to the principle of gravity action, and the operation is simple and practical. There is no scanning mechanism, which saves the workpiece from entering the press preparation time, the work cycle is shorter, and the work efficiency is higher.

6. The top block connection does not fall: the connection between the top block and the bottom plate is locked by an aluminum sleeve, which not only increases the strength of the aluminum plate, but also prevents the top block from being taken out when flipping and sucking, thereby prolonging the service life of the bottom plate.

7. Cover protection and safety: The equipment cover is beautiful in appearance and designed by professional industrial designers. The corresponding parts are also equipped with protective nets to achieve double protection.

8. Air film pressure: The equipment has two modes: air film pressure and silica gel film pressure. Users can choose the membrane pressure method at will. The choice is flexible and convenient, greatly improving the service life of the silicone membrane and saving the operating cost of the plant.

9. Fast suction speed: The vacuum pumping speed of the suction pump is 200 cubic meters per hour, the pumping speed is fast, and the pumping time is short.

10. High-quality oil cylinder: 8 cylinders of press, cylinder diameter is 180, Rexroth quality cylinder, greatly reducing the probability of oil leakage, improving the stability of the equipment, the jacking pressure is relatively abundant, and it is not easy to leak when charging positive pressure. After a few years of use, the base plate may undergo some deformation, and after the lifting pressure of the cylinder is raised, the press can continue to be used, which prolongs the service life of the press.

11. High yield: Since the photoelectric scanning mechanism is not required, there is no possibility that the yield of the workpiece is greatly reduced.

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall send technicians to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance

PVC Veneer Vacuum Membrane Laminating Press Machine

Introduction

It is used to work various high-profile PVC, hot transfer and single veneer

All kinds of PVC workpieces processed by this machine stick firmly, do not bounce off the edge.Line of groove is clear and in place.

Feature

The operating system adopts imported brand PLC control, which is convenient to control, advanced technology and high automation.

Household electrical appliances used in electrical system contactor use imported components, low fault rate.

The main engine of the hydraulic system USES Taiwan system, the motor and the oil pump USES Taiwan KOMPASS, the hydraulic system principle is the board type interpolation, the international advanced structure, the fault rate is low, the large flow, the pressure is rapid, effectively improves the production efficiency.

Equipment is added wrinkle resistant PVC, greatly improve the yield of the product, higher than that of normal pressure yield of 15-20 ℅.

Technical parameter

| Dimensions | 6400mm*1900mm*2150mm |

| Bed dimension | 2300mm*1100mm(inner diameter) |

| Maximum machining height | 50mm |

| Rated working pressure | positive pressure ≤0.4Mpa negative pressure≥-0.095Mpa |

| Total power | 23KW |

| Actual power consumption | About 6KW |

| Total weight | 11T |

Upgrade improvements

u The walking guide is made in Taiwan, and the workbench walks more smoothly.

u The racks are all sandblasted to enhance corrosion resistance.

u The lifting balance system is easy to adjust, and the rise and fall are more stable.

u Hydraulic system oil port improvement and maintenance is more convenient.

u The aluminum frame is processed by one body, and no weld seam increases the strength.

Component display

Electric component Air tank

Host housing Frame

List of main disc components (main panel length 1250mm, width 500mm) | ||||||||

No | Name | Model | Quantity (unit) | Manufacturer | ||||

1 | residual current operated circuit breaker | DZ15LE-1004901 | 1 | Chint | ||||

2 | Current Transformer | BH-0.66 | 3 | Chint | ||||

3 | low voltage fuse base(insurance) 6A fuse link | RT18-32 R015 | 5 5 | Chint | ||||

4 | Control Transformer | BK-50VA(380-220V) | 1 | Chint | ||||

5 | phase-phase sequence protection relay | XJ3-G | 1 | Chint | ||||

6 | plug-in relay (single open and single closed) Base socket | RXM2LB2P7 RXMZEM2C | 13 13 | Schneider | ||||

7 | plastic case circuit breaker | DZ108-20(5-8A) DZ108-20(5-3.2A) | 1 1 | Chint | ||||

8 | miniature circuit breaker | DZ47-60 | 4 | Chint | ||||

9 | 0910 Series AC Contactor | LC|E0910M5N | 3 | Schneider | ||||

10 | 2510 Series AC Contactor | LC|E2510M5N | 5 | Schneider | ||||

11 | 24V power supply | S-100-24 | 1 | Chint | ||||

12 | PLC host | VBO-32MR | 1 | Vigor | ||||

13 | PLC expansion slot | VB-8YR | 1 | Vigor | ||||

14 | PLC display | HITECH | 1 | Schneider | ||||

15 | E310 Series Inverter | E318-402-H3 | 1 | Vigor | ||||

16 | terminal block terminal block | TD-20A TB-4504 | 71 10 | Chint | ||||

17 | trunking | 500mm 890mm | 2 4 | Chint | ||||

List of panel components (length 450mm, width 385mm) | ||||||||

1 | Thermostat | HMT7 | 4 | TaiWan | ||||

2 | voltmeter | 82L1型 | 1 | Chint | ||||

3 | ammeter | 85L1型 | 3 | Chint | ||||

4 | green button | XB2-BA35 | 1 | Schneider | ||||

5 | red button | XB2-BD25 | 1 | Schneider | ||||

6 | single open button (single file) | XB2-BD25 | 6 | Schneider | ||||

7 | Emergency stop | XB2-BS545 | 1 | Schneider | ||||

Equipment maintenance

every 3-6 months, the vacuum pump changes oil once, and the filter is cleaned every 15 working days;

How it works

This machine adopts human-computer interface, easy to understand and operate, automatic double-station machine

v Preheating equipment

v Put product on the workbench

v Pull the PVC membrane and cover cabinet door

v Cutting membrane

v Enter the machine

v The membrane floating up and heating

v Vacuum plus negative pressure plus positive pressure

v Release of positive and negative pressure

v Unloading hydraulic

v Drop workbench

v Workbench out

v Flipped board sucking sample up

v Cut membrane

v Work end

This process is done automatically by one click

Silicone plate life

The silicone plate is imported from Korea and can be used for 3-4 months (about 1000 hours) and can be repaired. (This accessory is not covered by the warranty)

Differences from other machine

1. Low energy consumption: The press adopts nano heating mode, which has heat conduction heating and infrared radiation heating at the same time. The heating power per hour is about 10KW, which saves half of the electricity cost compared with other manufacturers. And the heating is even and reliable.

2, work efficiency: high yield of coated workpieces, fast work cycle, short cycle, a film finished product process is about 3 minutes and a half.

3, reduce labor costs: the machine operators always need 3-4 people, is one-half of the peer equipment. There are 2 people in the table, 1 person in the station (1 person can be borrowed from the table), 1 person in the trimming position; 6 people in the same position, 2 people in the table, 1 person in the station, pull The film position is 2 people, and the trimming position is 1 person.

4, large capacity: standard operation 350-400 flat / day, peers are 320-360 flat / day; non-standard operation 230-270 flat / day, peers are 200-240 flat / day.

5. The lifting of the top block is faster: the top block can realize the locking of the corresponding height due to the principle of gravity action, and the operation is simple and practical. There is no scanning mechanism, which saves the workpiece from entering the press preparation time, the work cycle is shorter, and the work efficiency is higher.

6. The top block connection does not fall: the connection between the top block and the bottom plate is locked by an aluminum sleeve, which not only increases the strength of the aluminum plate, but also prevents the top block from being taken out when flipping and sucking, thereby prolonging the service life of the bottom plate.

7. Cover protection and safety: The equipment cover is beautiful in appearance and designed by professional industrial designers. The corresponding parts are also equipped with protective nets to achieve double protection.

8. Air film pressure: The equipment has two modes: air film pressure and silica gel film pressure. Users can choose the membrane pressure method at will. The choice is flexible and convenient, greatly improving the service life of the silicone membrane and saving the operating cost of the plant.

9. Fast suction speed: The vacuum pumping speed of the suction pump is 200 cubic meters per hour, the pumping speed is fast, and the pumping time is short.

10. High-quality oil cylinder: 8 cylinders of press, cylinder diameter is 180, Rexroth quality cylinder, greatly reducing the probability of oil leakage, improving the stability of the equipment, the jacking pressure is relatively abundant, and it is not easy to leak when charging positive pressure. After a few years of use, the base plate may undergo some deformation, and after the lifting pressure of the cylinder is raised, the press can continue to be used, which prolongs the service life of the press.

11. High yield: Since the photoelectric scanning mechanism is not required, there is no possibility that the yield of the workpiece is greatly reduced.

Tool List | ||

Name | Unit | Quantity |

1. spanner12×14 | bundle | 1 |

2. Hexagon spanner | set | 1 |

3. Phillips screwdriver | bundle | 1 |

4. slot type screwdriver | bundle | 1 |

5. pvc bracket | set | 2 |

6. pvc branch | stick | 2 |

7. fuse | stick | 2 |

8. spanner17×19 | bundle | 1 |

9. O-ring | pcs | 5 |

10.compound gasket | pcs | 5 |

11. Limit switch | pcs | 1pcs entry table 1pcs workbench out |

12. ScrewsM8*30 | pcs | 12 |

13. Nuts M8*30 | pcs | 12 |

14. ScrewsM6*30 | pcs | 10 |

15. Nuts M6*30 | pcs | 10 |

Warranty

1. In order to ensure that the demander can use the equipment normally, the warranty period is one year, except for consumables (pressure buckle, gas strut). The supplier will provide free warranty service during the warranty period, non warranty period provide free consultation and troubleshooting for repair, maintenance. The warranty period is calculated from the day when the equipment is shipped.

2. The warranty does not include: damage caused by man-made and natural disasters. (such as fire, flood, earthquake)

3. If the equipment occurs error, The supplier shall provide free qualified parts and maintenance during the warranty period; outside the warranty period, the supplier shall provide the demand at a preferential price for a long time. The cost incurred by the supplier for maintenance shall be settled by both parties through negotiation

4. The supplier shall send technicians to the demander to install and debug the equipment, and train the demander's personnel in practical operation, processing and maintenance